Novel multi-effect water distillation machine

A distilled water machine, a new type of technology, applied in water/sewage treatment, heating water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of impurity, waste, and untimely recycling of distilled water, to ensure purity, guarantee The effect of rational use and avoidance of energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

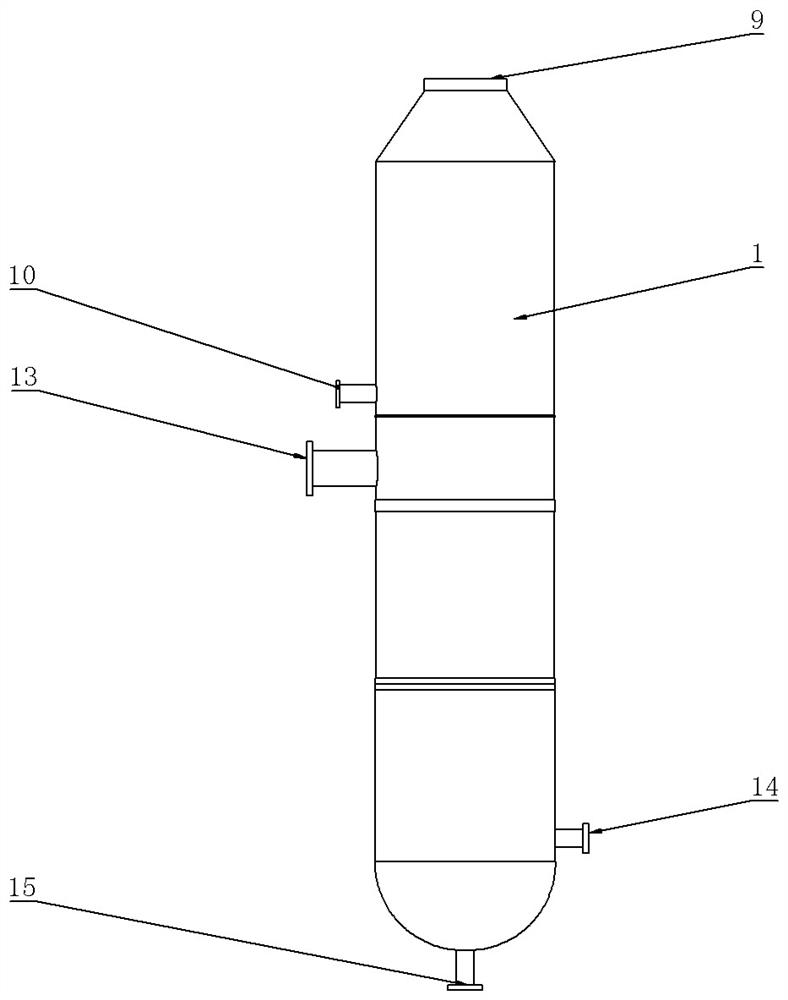

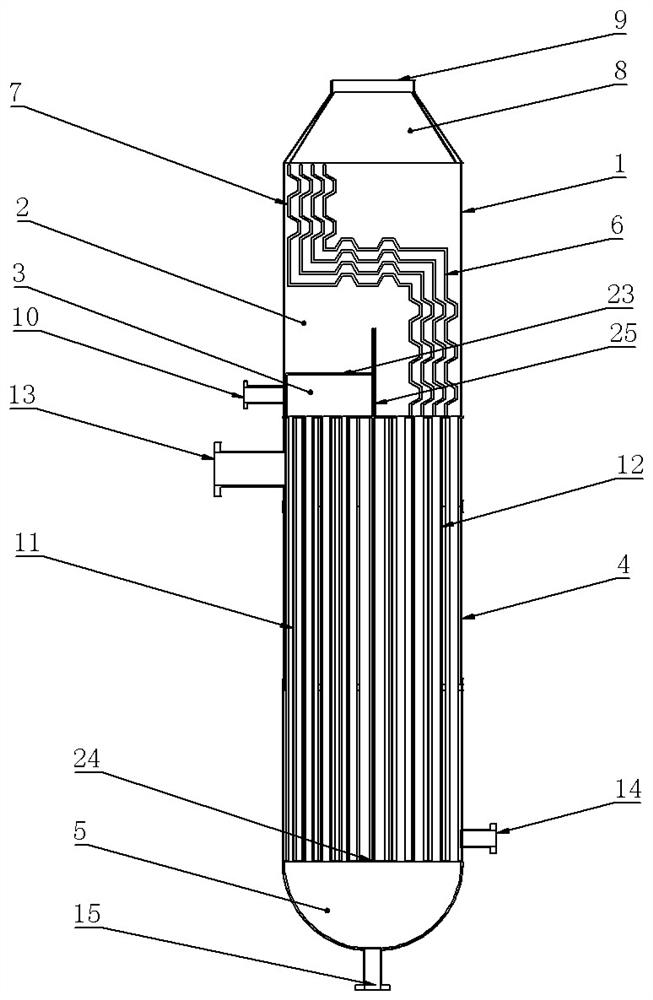

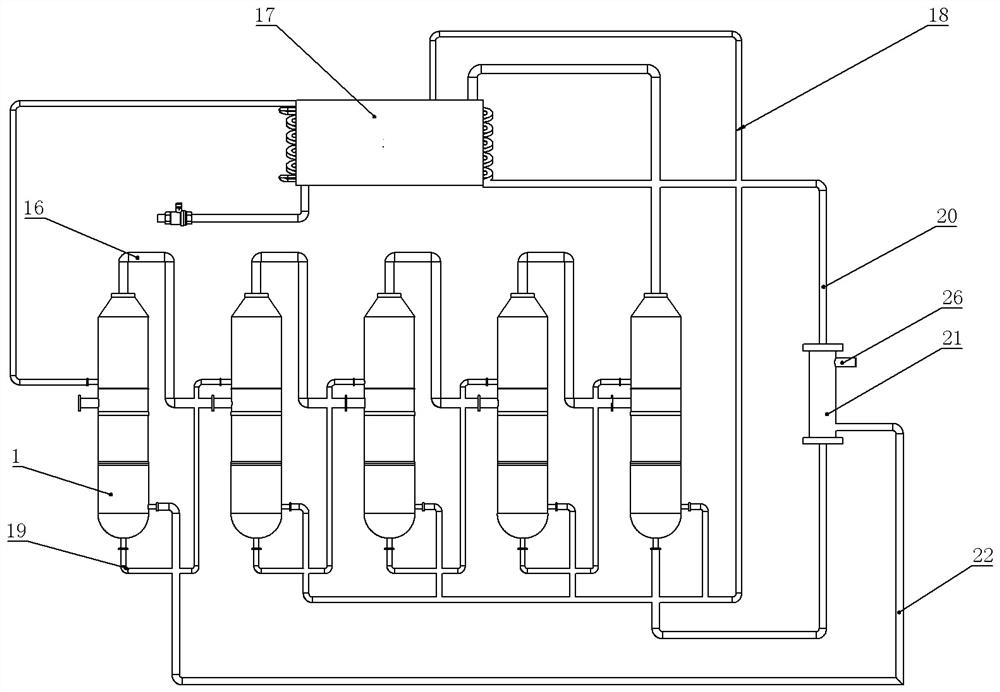

[0019] Specific implementation method: combined Figure 1-3 As shown, a novel multi-effect distilled water machine is characterized in that it includes several single-effect distilled water machines 1, and the inside of the distilled water machine 1 includes an upper gas-liquid separation chamber 2, a middle falling film water chamber 3, and a lower rising The falling film evaporation chamber 4 and the rising film water chamber 5 at the bottom; the inside of the gas-liquid separation chamber 2 is provided with a number of baffles 6, and the vertical connection between the baffles 6 forms a stepped baffle 7, The top of the stepped baffle 7 is connected with a spiral separator 8, and the top of the gas-liquid separation chamber 2 is a water vapor outlet 9; one side of the outer wall of the falling film water chamber 3 is provided with a purified water inlet 10 , the interior of the rising film falling film evaporation chamber 4 is provided with a number of rising film tubes 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com