Multi-layer melt-blown non-woven fabric and preparation method thereof

A melt-blown non-woven fabric and melt-blown technology, applied in the directions of non-woven fabrics, textiles and papermaking, fiber types, etc., can solve the problems of small variable degree, small fiber diameter, singleness, etc., and achieve the goal of improving filtration efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

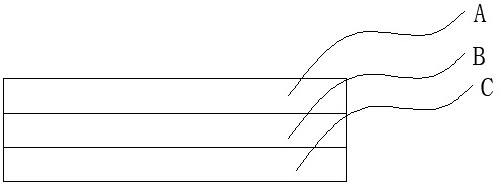

[0031] Refer to attached figure 1 , 2 , a multi-layer melt-blown non-woven fabric is composed of A layer of melt-blown non-woven fabric, B layer of melt-blown non-woven fabric, and C layer of melt-blown non-woven fabric. Spray non-woven fabric, layer B melt-blown non-woven fabric is provided with C-layer melt-blown non-woven fabric.

[0032] A multi-layer melt-blown non-woven fabric is a melt-blown non-woven fabric composed of three different fiber diameters: A-layer melt-blown non-woven fabric, B-layer melt-blown non-woven fabric, and C-layer melt-blown non-woven fabric.

[0033] Among them, the layer A melt-blown non-woven fabric belongs to the primary filter layer, which mainly filters particles above 40um.

[0034] The layer A melt-blown non-woven fabric is made of polypropylene through a melt-blown process.

[0035] The fiber diameter of the layer A melt-blown non-woven fabric is 5-15 denier (denier).

[0036] The grammage of the melt-blown non-woven fabric of the A l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com