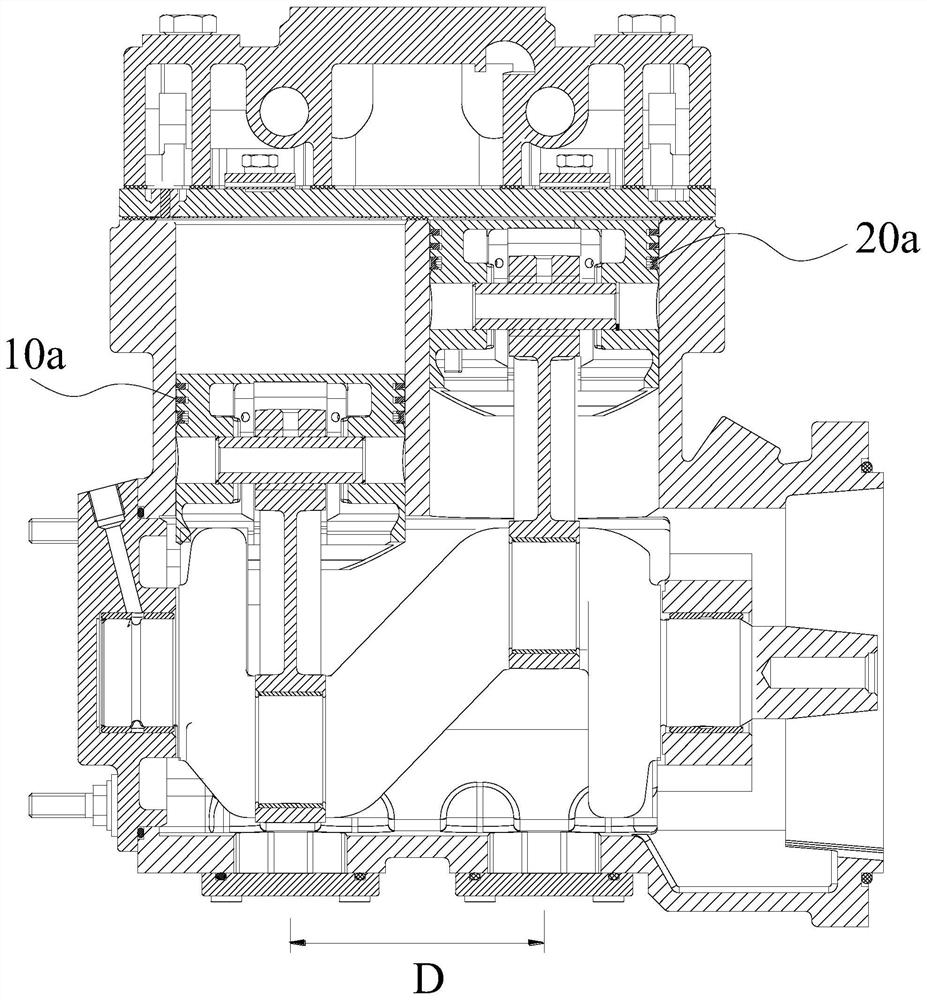

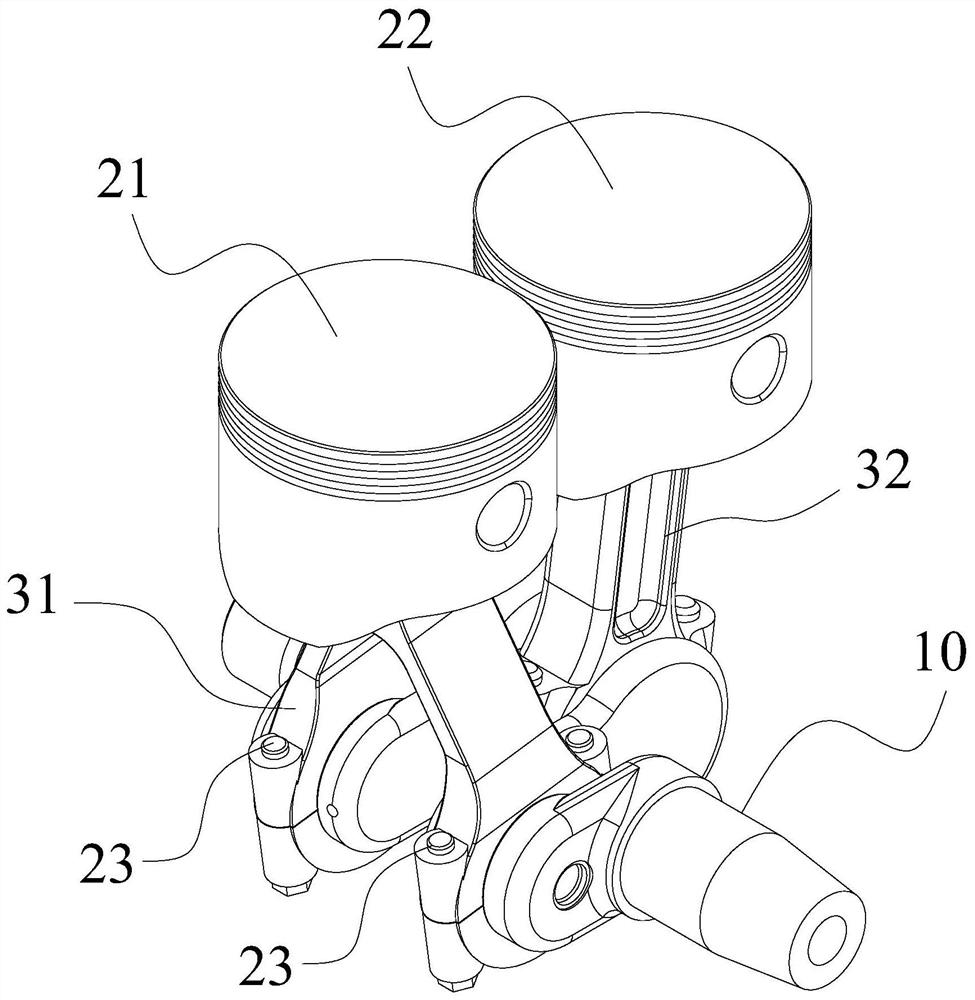

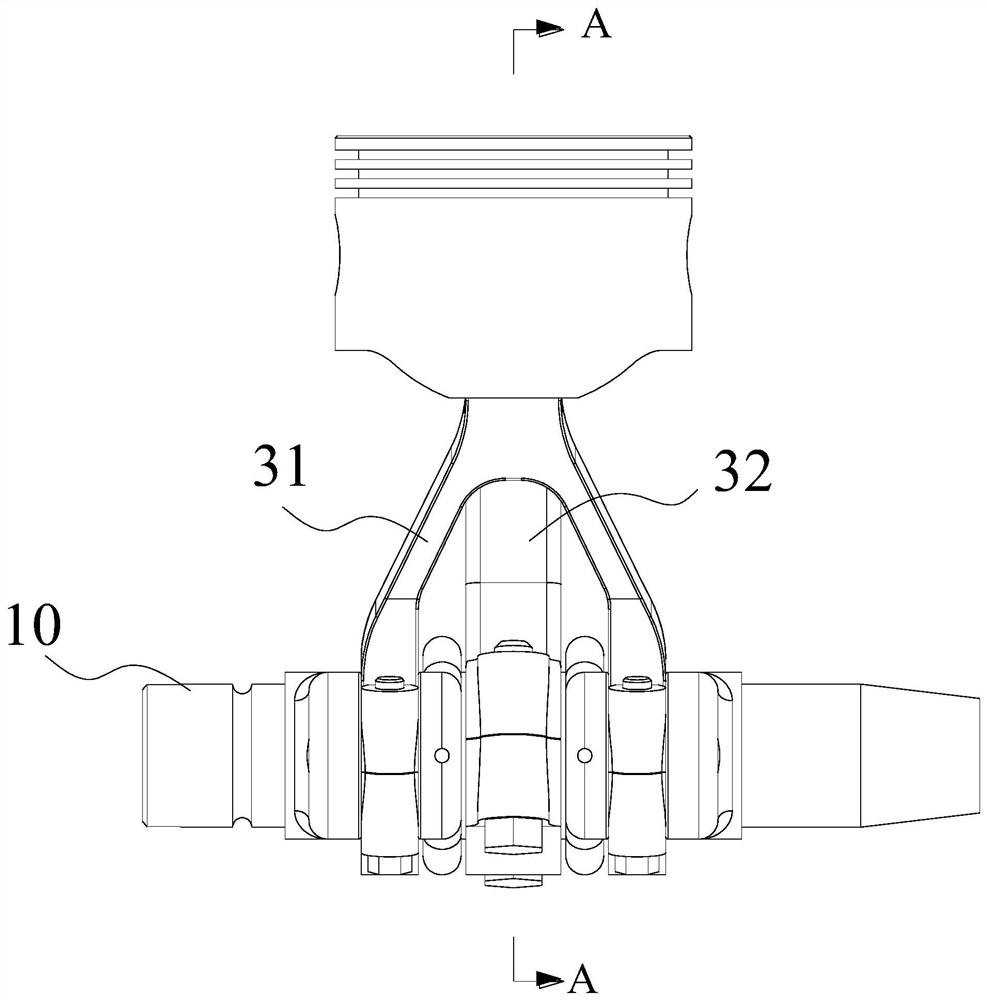

Two-stage compressed air compressor

A technology for compressing air and compressors, which is applied to multi-stage pumps, mechanical equipment, machines/engines, etc. It can solve problems such as insufficient compression, large energy loss, and low gas compression efficiency, so as to reduce vibration amplitude and alleviate vibration problems , the effect of service life guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] An embodiment of a two-stage compressed air compressor according to the present invention will be described below with reference to the accompanying drawings. As those skilled in the art would realize, the described embodiments may be modified in various different ways, all without departing from the spirit and scope of the present invention. Accordingly, the drawings and description are illustrative in nature and not intended to limit the scope of the claims. Also, in this specification, the drawings are not drawn to scale, and like reference numerals denote like parts.

[0041] It should be noted that the expressions "first" and "second" used in the embodiments of the present invention are used to distinguish between two entities with the same name but different parameters or different parameters. It can be seen that "first" and "second " is only for the convenience of expression, and should not be understood as a limitation on the embodiments of the invention, and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com