Drying device for food processing

A drying device and food processing technology, which is applied in the direction of drying gas arrangement, drying solid materials, and dry cargo handling, etc. It can solve the problems of mixing mechanism, limited mixing area, limited range, unfavorable uniform distribution of hot water vapor, etc., and achieves good drying effect , uniform heating, and the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

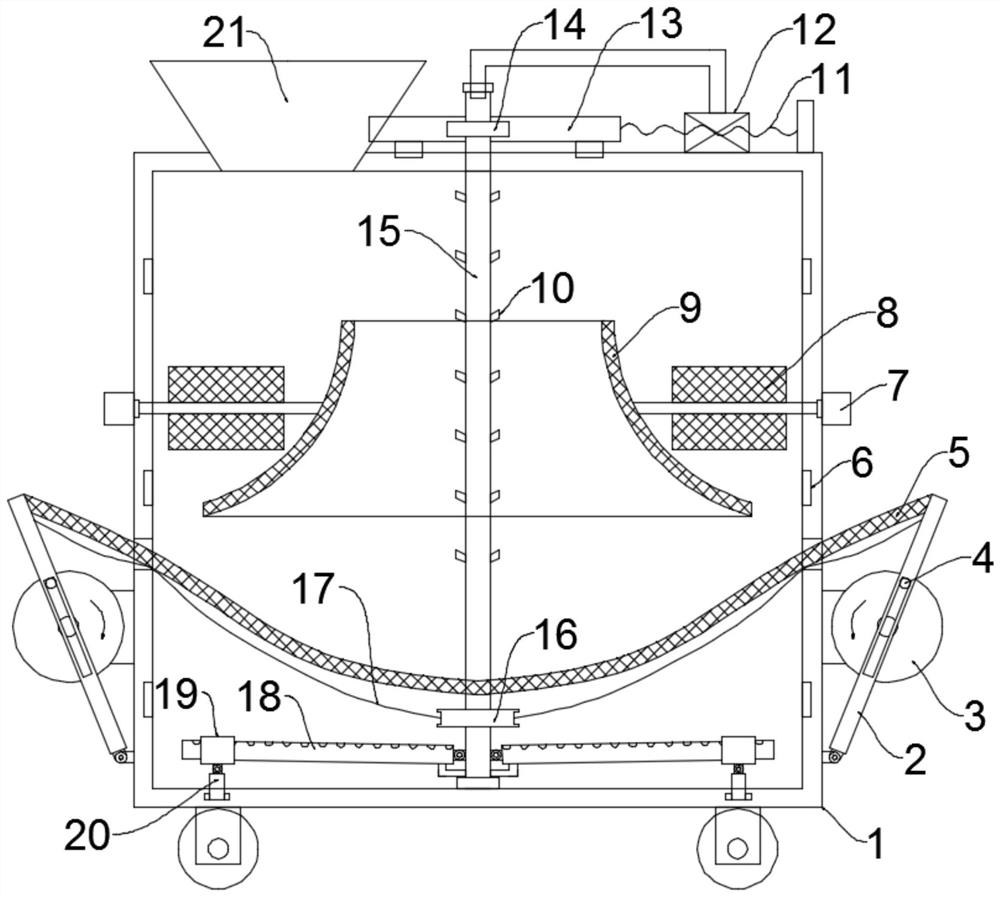

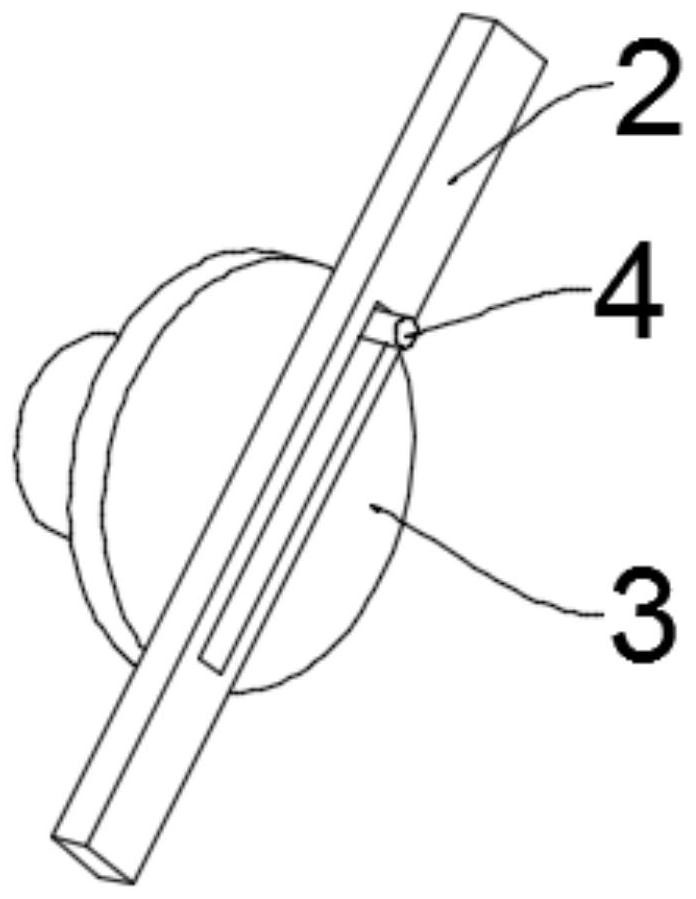

[0024] See Figure 1~3 In the embodiment of the present invention, a drying device for food processing includes a box body 1 and a drying unit. The bottom of the box body 1 is uniformly and symmetrically fixed with rollers to facilitate the movement of the device. The top of the box body 1 is provided with a hopper 21 A box door is installed on the box body 1 to facilitate material retrieval and maintenance. In this embodiment, the box door is preferably installed on the box body 1 through hinges and buckles, and a plurality of electric heating elements are installed on both side walls of the box body 1. 6. The drying unit includes a dispersing assembly for dispersing materials and an air jet assembly for spraying hot air for drying. The dispersing assembly includes a support net 5, a first motor, a disc 3 and a drive rod 2. The support The net 5 is set in the lower part of the inner cavity of the box 1 for placing raw materials. The width of the supporting net 5 is not less th...

Embodiment 2

[0028] See Figure 4 The difference between the embodiment of the present invention and the embodiment 1 is that the top of the box body 1 is provided with an exhaust port, and an exhaust fan 23 is installed at the exhaust port on the box body 1 to quickly extract water vapor. Speed up the drying speed.

[0029] The working principle of the present invention is: start the first motor, the first motor drives the disc 3 to rotate, and the disc 3 drives the drive rod 2 to reciprocate, such as figure 1 As shown, when the driving rod 2 rotates to the side close to the box body 1, the supporting net 5 gradually sinks. When the driving rod 2 swings to the side away from the box body 1, due to the quick return characteristic, the supporting net 5 is quickly pulled outward, so that The raw material on the support net 5 obtains a relatively high speed, scatters upwards, is fully and evenly heated, and improves the drying efficiency; when the driving rod 2 rotates to the side close to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com