Workpiece surface defect detection method and system based on SSD network model

A workpiece surface and network model technology, applied in the direction of instruments, scanning probe technology, etc., can solve the problem of reducing the workload of manual design features, and achieve the effect of strengthening network continuity, reducing workload, and increasing network complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

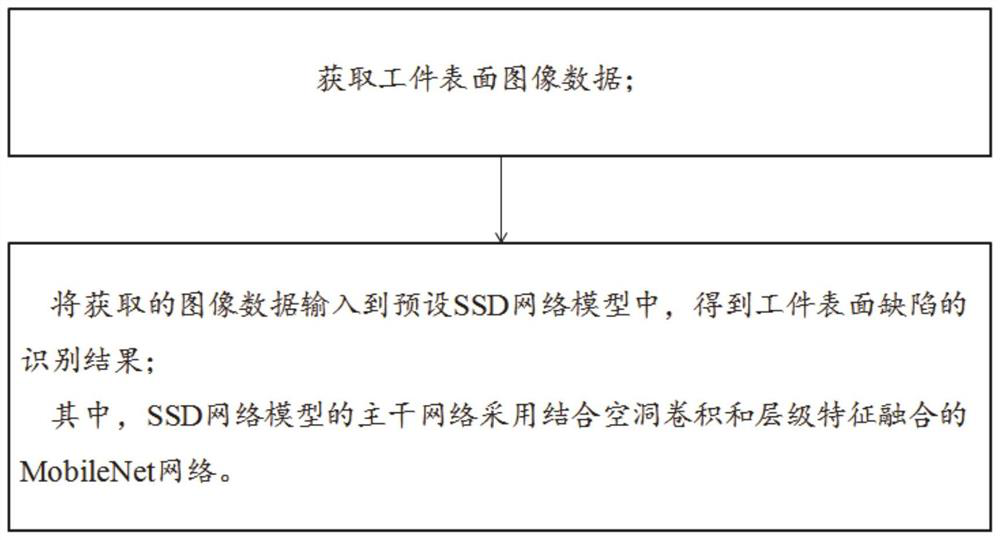

[0047] like figure 1 As shown, embodiment 1 of the present disclosure provides a method for detecting workpiece surface defects based on SSD network model, comprising the following steps:

[0048] Obtain image data of workpiece surface;

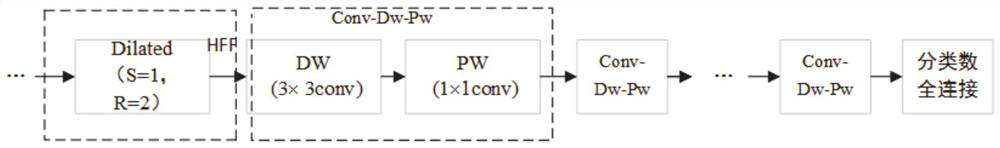

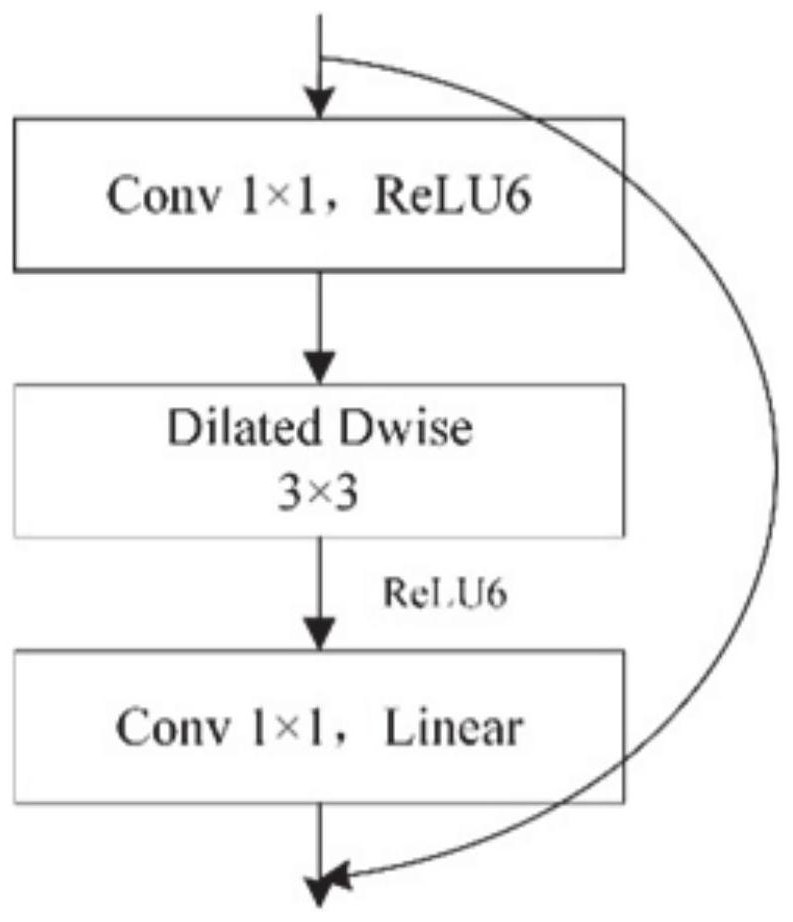

[0049] Input the acquired image data into the preset SSD network model to obtain the recognition result of workpiece surface defects;

[0050] Among them, the backbone network of the SSD network model adopts the MobileNet network combined with hole convolution and hierarchical feature fusion.

[0051] In detail, include the following:

[0052] S1: Image acquisition, using a scanning electron microscope to acquire images of workpiece surface defects at different positions, and then sending them to the image analysis stage.

[0053] SEM image acquisition involves the following steps:

[0054] S1.1: Put nitrogen into the sample exchange chamber until the light is on;

[0055] S1.2: Open the sample exchange chamber, put the sample stage with...

Embodiment 2

[0084] Embodiment 2 of the present disclosure provides a workpiece surface defect detection system based on an SSD network model, including:

[0085] The data acquisition module is configured to: acquire workpiece surface image data;

[0086] The defect recognition module is configured to: input the acquired image data into the preset SSD network model to obtain the recognition result of the workpiece surface defect;

[0087] Among them, the backbone network of the SSD network model adopts the MobileNet network combined with hole convolution and hierarchical feature fusion.

[0088] The working method of the system is the same as the method for detecting workpiece surface defects based on the SSD network model provided in Embodiment 1, and will not be repeated here.

Embodiment 3

[0090] Embodiment 3 of the present disclosure provides a workpiece surface defect detection system based on an SSD network model, including a scanning electron microscope, a high-performance server, and a control terminal;

[0091] The scanning electron microscope is configured to collect workpiece surface image data;

[0092] The high-performance server is configured to perform the following method:

[0093] Obtain image data of workpiece surface;

[0094] Input the acquired image data into the preset SSD network model to obtain the recognition result of workpiece surface defects;

[0095] Among them, the backbone network of the SSD network model adopts the MobileNet network combined with hole convolution and hierarchical feature fusion.

[0096] The detailed steps are the same as the SSD network model-based workpiece surface defect detection method provided in Embodiment 1, and will not be repeated here.

[0097] The control terminal includes input devices such as a keybo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com