Device and method for detecting coking condition of water-cooled wall based on mid-infrared holographic imaging

A holographic imaging and water-cooled wall technology, which is applied in measurement devices, optical devices, phase influence characteristic measurement, etc., to reduce coking, improve operating efficiency, and reduce equipment loss and accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

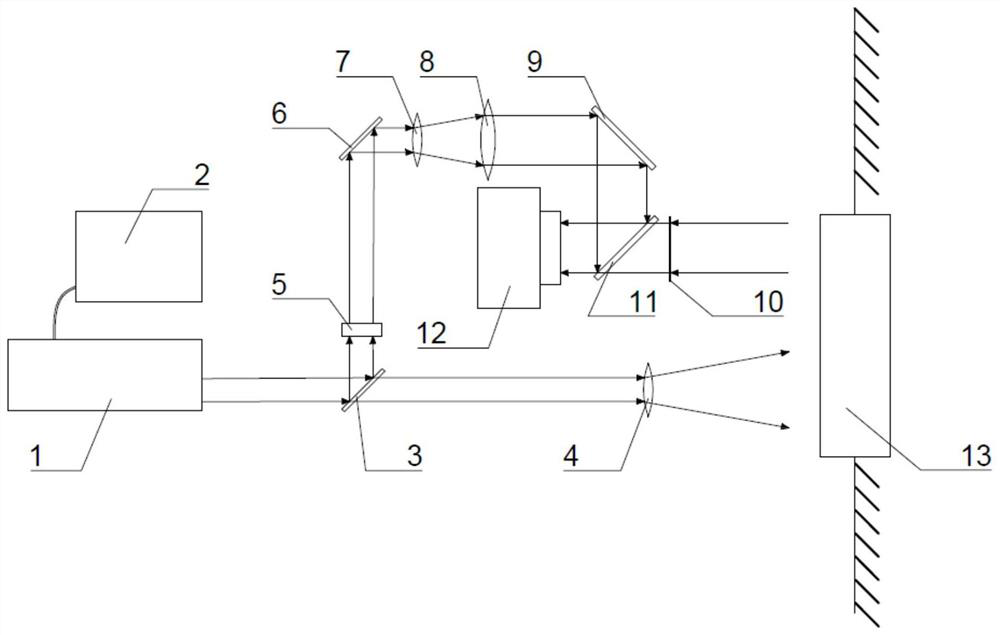

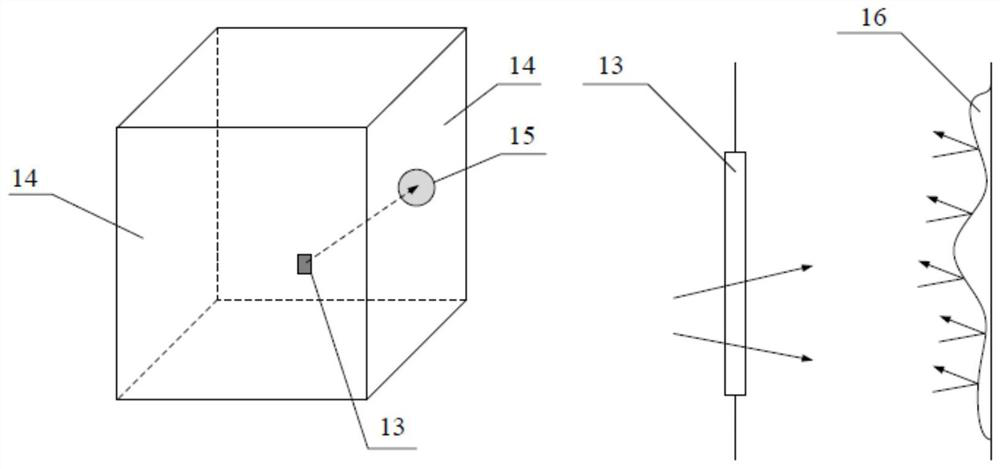

[0052] The device and method for detecting coking of the water wall based on mid-infrared holographic imaging provided in this embodiment are as follows: figure 1 with figure 2 shown.

[0053] Specifically, in this embodiment, the laser light with a wavelength of 10.6 μm emitted by the carbon dioxide laser 1 is divided into two laser beams by the beam splitter 3, which are respectively transmitted light and reflected light, and the intensity ratio of the two is 9:1; the transmitted light After passing through the first focusing lens 4, divergent incident light is formed, passes through the fire viewing hole 13 on the water cooling wall, and irradiates on the measured area 15 of the furnace water cooling wall. The focal length of the first focusing lens 4 can be determined according to The size and distance are selected; the incident light is scattered by the surface of the water wall or the coke surface 16 to form the object light, and after passing through the narrow-band f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com