Pointer type pressure gauge automatic calibrator indicating value reading method based on machine vision

A technology for indication readings and pressure gauges, which is applied to the measurement of fluid pressure, calibration/testing of force/torque/power measuring instruments, instruments, etc., and can solve cumbersome manual calculations, heavy tasks for testers, and inconsistent visual errors in manual readings And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

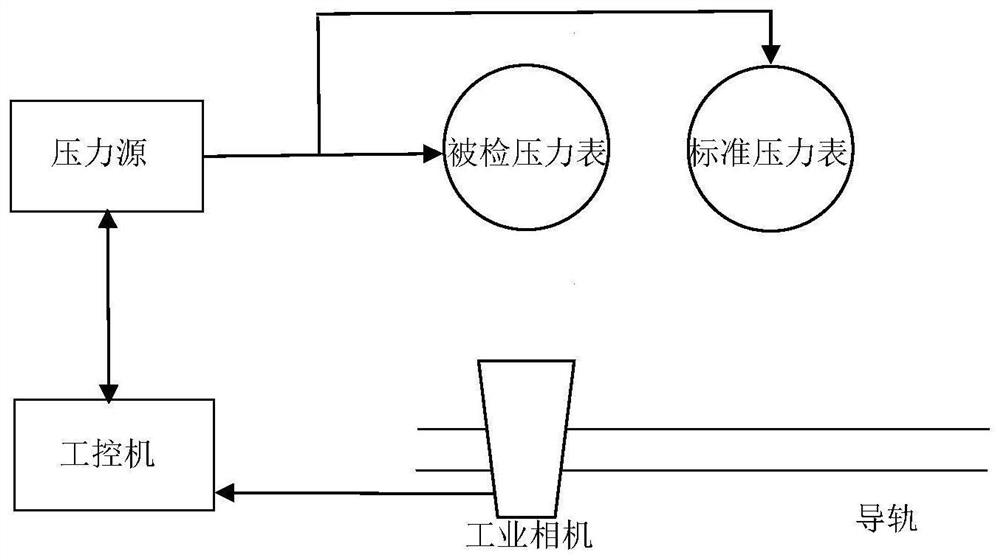

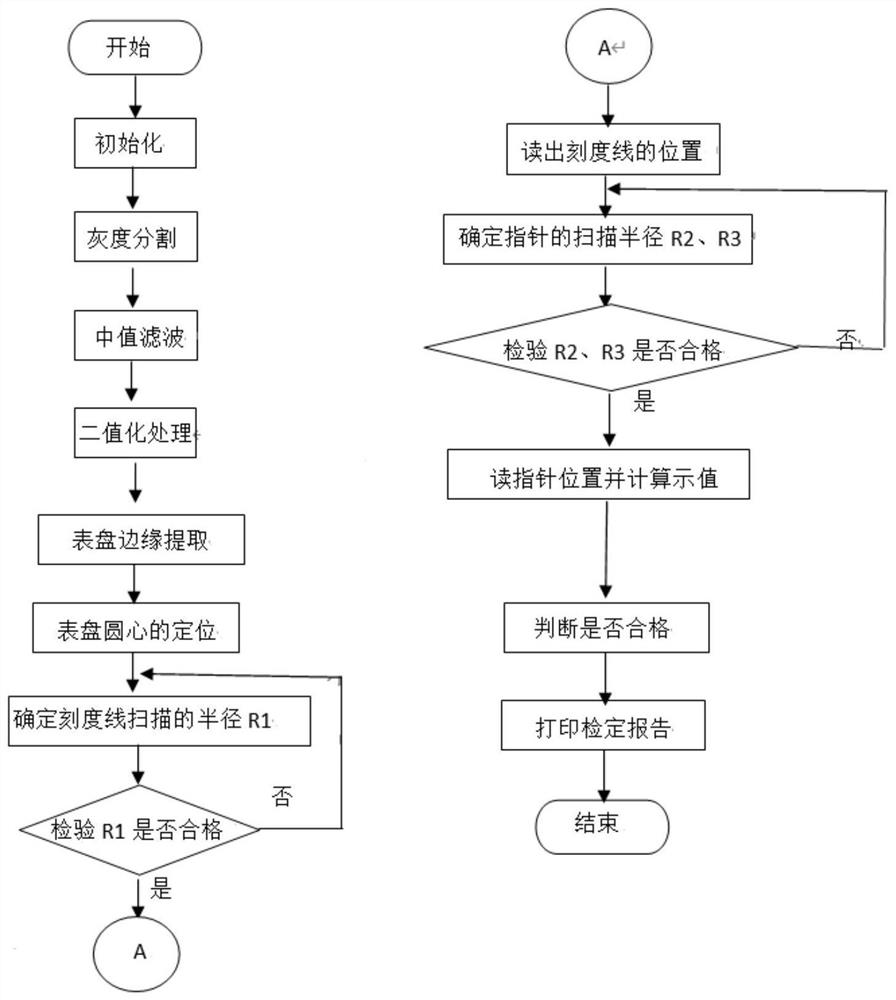

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. In the image of the pressure gauge in this embodiment, the actual size of the dial is 150 mm in outer diameter, and the range of the pressure gauge is 2.5 MPa.

[0017] (1) Firstly, grayscale operation is performed on the collected pressure gauge image, and then noise reduction processing is performed on it. In this embodiment, adaptive median filtering is used to complete the image filtering process. The specific process is as follows:

[0018] Define a rectangular window S of m×n xy as a filter area. Define the following variables in this area: Z min is S xy The minimum gray value in Z, Z max is S xy The maximum gray value in Z med is S xy Medium gray average, Z xy is the gray value at coordinates (x, y), S MAX is S xy The maximum size allowed. The adaptive median ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com