Control circuit and control method for industrial camera system time sequence

A technology of industrial cameras and control circuits, which is applied in the direction of program control, program control, and electrical program control in sequence/logic controllers. Impact on lifespan, enhance control, and provide system stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following, specific examples will be used to describe in detail and illustrate the technical solutions of the present invention.

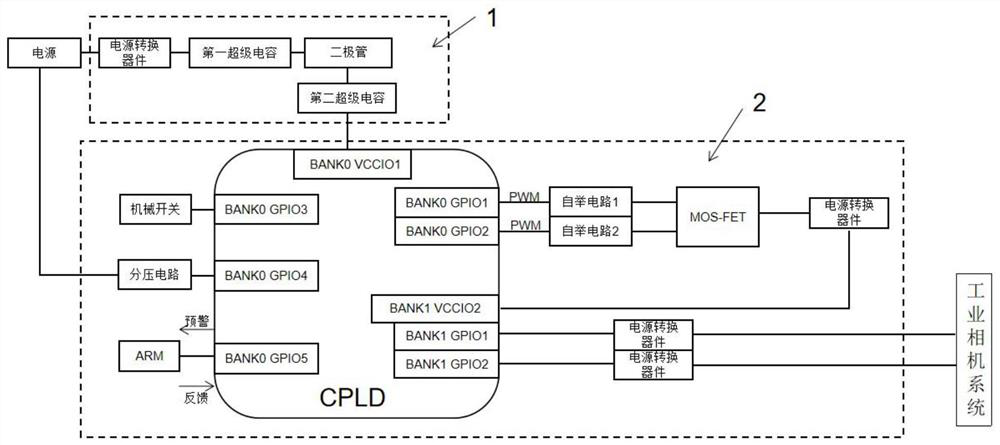

[0037] Such as figure 1 As shown, the control circuit schematic diagram of the industrial camera system timing is given. The control circuit includes an energy storage circuit 1 and a power-on sequence control circuit 2. The energy storage circuit 1 includes two sets of supercapacitors, namely the first supercapacitor and the second supercapacitor Two supercapacitors, a power conversion device is provided between the input terminal of the first supercapacitor and the input power supply, usually directly purchased power conversion modules (220V to 48V / 24V / 12V) or power adapters. Here, the number of supercapacitors in the first and second supercapacitors is 1, and the capacity is selected according to the overall power consumption of the system and the required application scenarios. A diode is connected in series between the first and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com