Low-temperature sterilizing process of raisins for fructus arecae immaturi

A technology for raisins and dried betel nut, applied in the field of raisin processing, can solve the problems of thin raisin skin and easily damaged water absorption, unsatisfactory sterilization effect, influence on the quality of dried betel nut, etc., and achieves the effects of consolidating sterilization effect, improving taste and flavor, and inhibiting bacterial reproduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A low-temperature sterilization process for raisins for dried betel nut, including the following steps:

[0023] S1. Select green raisins without mildew, no rot, and intact fruit, and freeze the green raisins at -20°C for 3 minutes to obtain frozen raisins;

[0024] S2. After cleaning the chicken feces vine leaves, add 2 times the mass of water, add 2% chicken feces vine leaves mass vinegar and 1% salt to squeeze the juice, filter to prepare chicken feces vine juice; put the frozen raisins in the chicken In the dung vine juice, the mass ratio of the two is 1:0.8, soak and sterilize at 0℃ for 25 minutes to obtain the raisins after sterilization;

[0025] S3. Rinse the raisins processed in step S2 with ultrapure water, the rinse time is 2min, the ultrapure water temperature is 5℃, and the pulsed strong light sterilization is placed after the rinse, the pulsed strong light sterilization intensity is 4J / cm 2 , The flashing distance is 16cm, the flashing time is 15s, the flashing i...

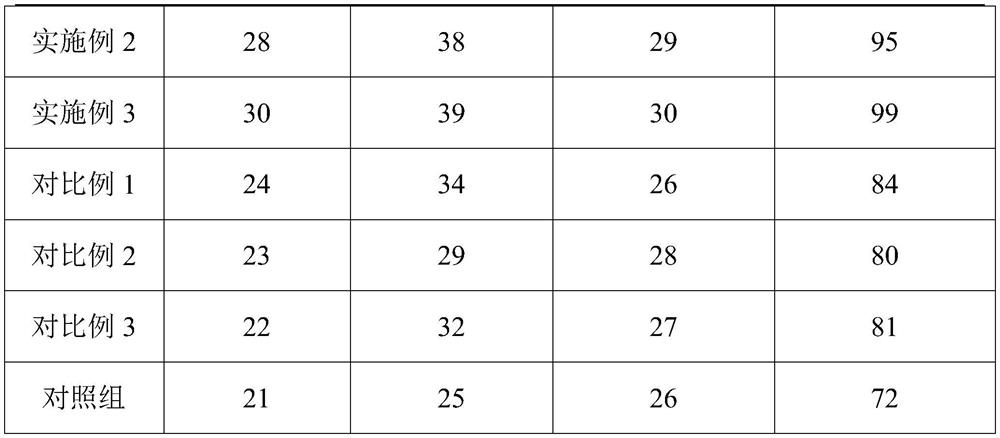

Embodiment 2

[0028] A low-temperature sterilization process for raisins used for dried betel nut, including the following steps:

[0029] S1. Select green raisins without mold, rot, and intact fruit, and freeze the green raisins at -15°C for 5 minutes;

[0030] S2. After cleaning the chicken feces vine leaves, add 4 times the mass of water, add chicken feces vine leaves 3% vinegar and 0.5% salt to squeeze the juice, filter to prepare chicken feces vine juice; put the frozen raisins in the chicken In the dung vine juice, the mass ratio of the two is 1:1.2, soak and sterilize at 4°C for 30 minutes to obtain a sterilized raisin;

[0031] S3. Rinse the raisins treated in step S2 with ultrapure water, the rinse time is 4min, the temperature of ultrapure water is 8℃, and the leaching is placed in pulsed strong light for sterilization, the pulsed strong light sterilization intensity is 5J / cm 2 , The flashing distance is 22cm, the flashing time is 12s, the flashing is 5 times per second, and the raisins ...

Embodiment 3

[0034] A low-temperature sterilization process for raisins for dried betel nut, including the following steps:

[0035] S1. Choose green raisins without mildew, no rot, and intact fruit, and freeze the green raisins at -18°C for 4 minutes;

[0036] S2. After cleaning the chicken feces vine leaves, add 3 times the mass of water, add 2.3% vinegar of chicken feces vine leaves and 0.8% salt to squeeze the juice, filter to prepare chicken feces vine juice; put the frozen raisins in the chicken In the dung vine juice, the mass ratio of the two is 1:1, soak and sterilize at 0°C for 30 minutes to obtain the raisins after sterilization;

[0037] S3. Rinse the raisins treated in step S2 with ultrapure water, the rinse time is 3min, the ultrapure water temperature is 7℃, and the pulsed strong light is used for sterilization after the rinse, the pulsed strong light sterilization intensity is 5J / cm 2 , The flashing distance is 19cm, the flashing time is 13s, the flashing is 5 times per second, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com