Jet-assisted multi-pulse-width laser peeling method for crystal ingot

An ingot and pulse width technology, applied in laser welding equipment, electrical components, circuits, etc., can solve the problems of poor processing efficiency, reduced processing efficiency, and high hardware cost, so as to improve peeling efficiency and quality, improve processing efficiency, The effect of continuous processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

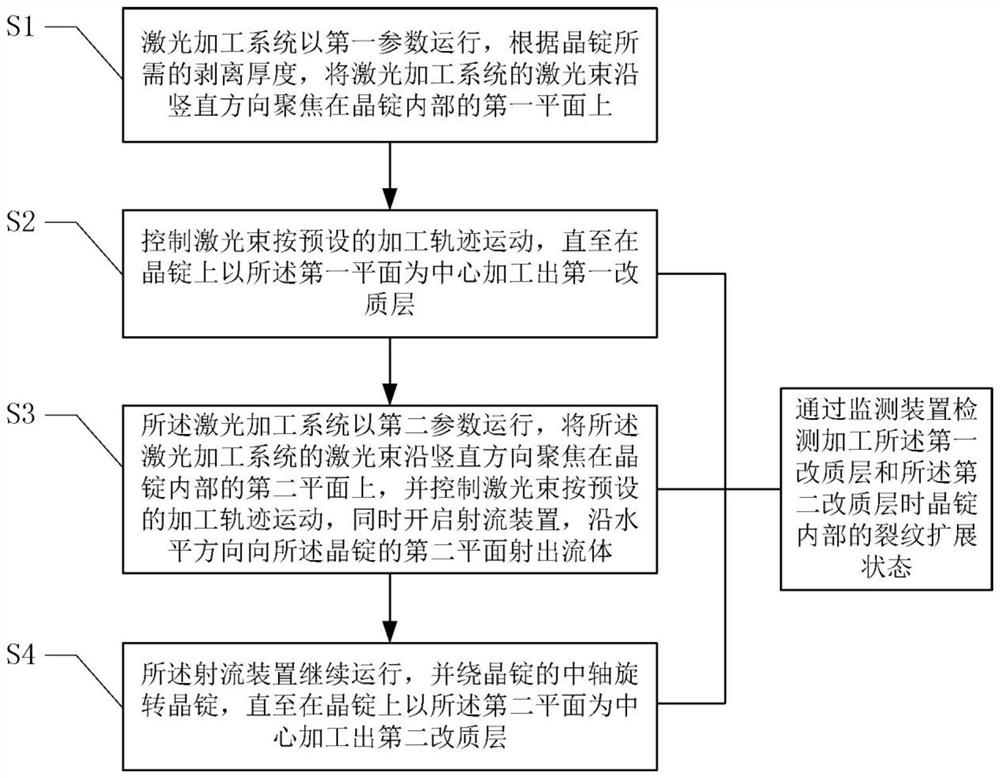

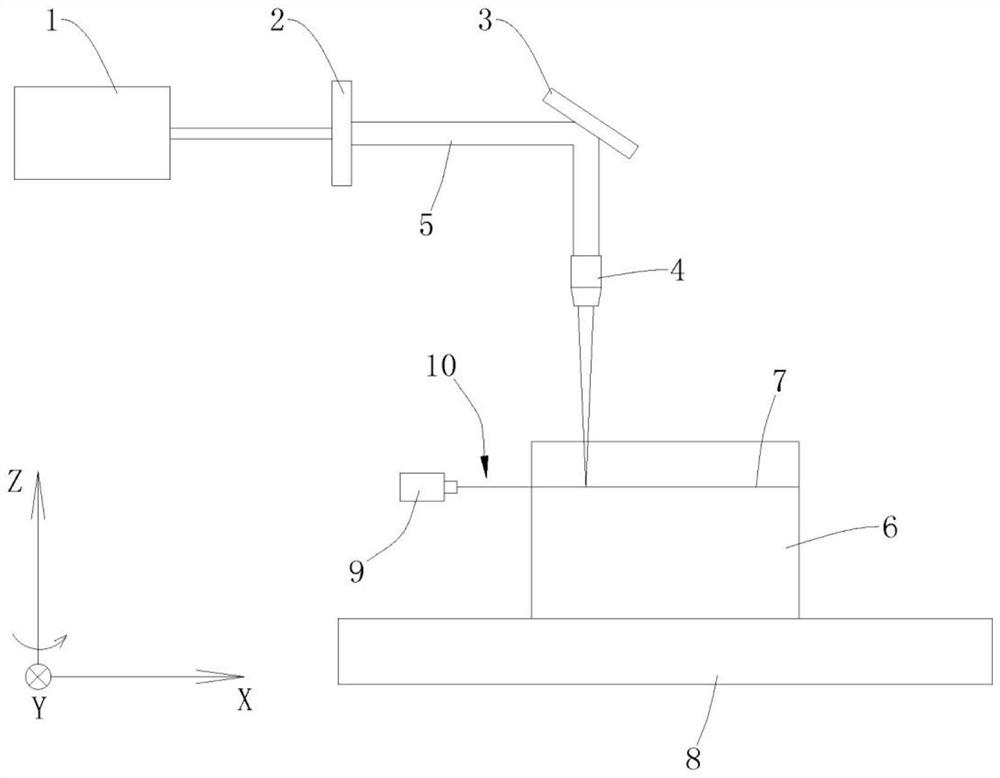

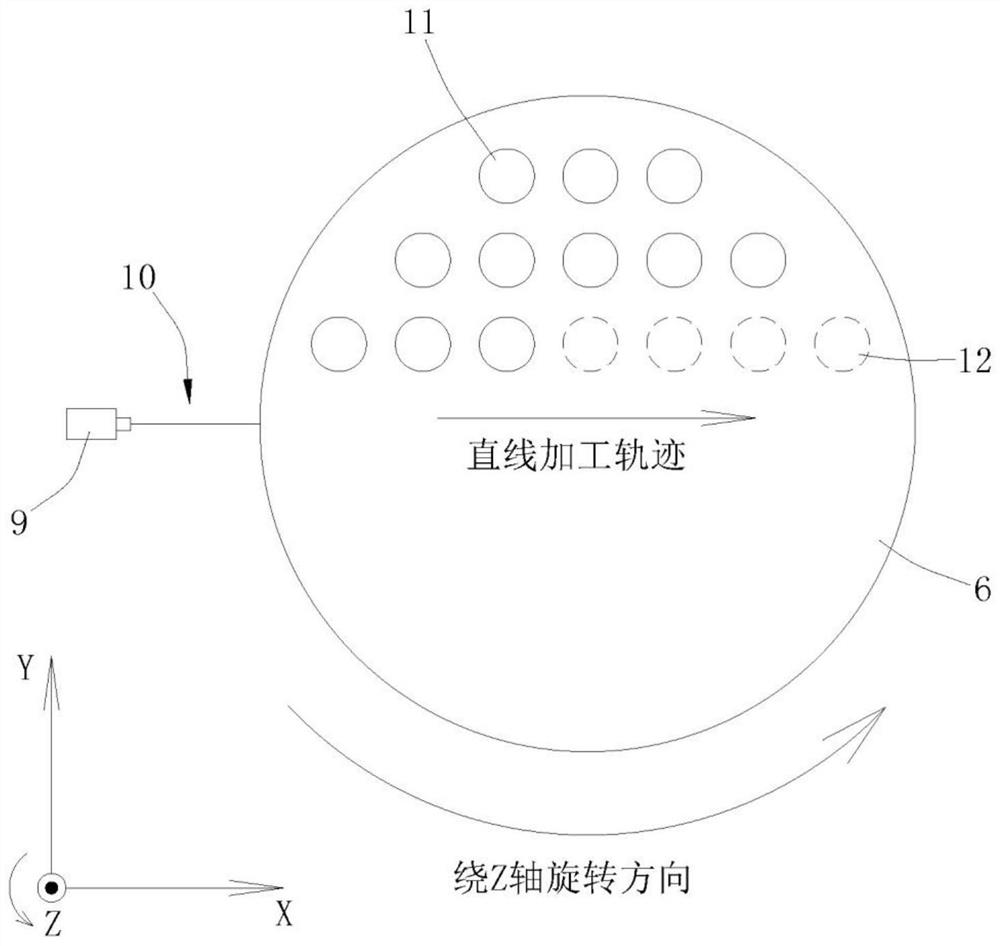

[0066] This embodiment provides a jet-assisted multi-pulse width laser crystal ingot stripping method, specifically:

[0067] Workers or robots fix the crystal ingot 6 on the fixture of the precision motion platform 8 in advance, move the crystal ingot 6 along the X-axis and Y-axis direction, and determine the initial processing position of the crystal ingot 6 on the X-axis and Y-axis. The position is located at the edge of the crystal ingot 6, the laser processing system is set as the first parameter, the laser beam 5 of the laser processing system is focused on the first plane 500 μm away from the upper surface of the crystal ingot 6 along the vertical direction, starting from the initial processing position, Use the laser beam 5 with a pulse width of 300fs, a wavelength of 1030nm, a power of 1.5W, and a repetition rate of 100kHz to move according to the preset linear processing trajectory at a speed of 150mm / s until the laser beam 5 moves along the processing trajectory and ...

Embodiment 2

[0070] This embodiment provides a jet-assisted multi-pulse width laser crystal ingot stripping method, specifically:

[0071] Workers or robots fix the crystal ingot 6 on the fixture of the precision motion platform 8 in advance, move the crystal ingot 6 along the X-axis and Y-axis direction, and determine the initial processing position of the crystal ingot 6 on the X-axis and Y-axis. The position is located at the edge of the crystal ingot 6, the laser processing system is set as the first parameter, the laser beam 5 of the laser processing system is focused on the first plane 450 μm away from the upper surface of the crystal ingot 6 along the vertical direction, starting from the initial processing position, Use the laser beam 5 with a pulse width of 800fs, a wavelength of 1064nm, a power of 1.2W, and a repetition rate of 120kHz to move according to the preset linear processing trajectory at a speed of 130mm / s until the laser beam 5 moves along the processing trajectory and ...

Embodiment 3

[0074] This embodiment provides a jet-assisted multi-pulse width laser crystal ingot stripping method, specifically:

[0075] Workers or robots fix the crystal ingot 6 on the fixture of the precision motion platform 8 in advance, move the crystal ingot 6 along the X-axis and Y-axis direction, and determine the initial processing position of the crystal ingot 6 on the X-axis and Y-axis. The position is located at the edge of the crystal ingot 6, the laser processing system is set as the first parameter, the laser beam 5 of the laser processing system is focused on the first plane 550 μm away from the upper surface of the crystal ingot 6 along the vertical direction, starting from the initial processing position, The laser beam 5 with a pulse width of 10ps, a wavelength of 532nm, a power of 1W, and a repetition rate of 80kHz is used to process the trajectory according to the preset curve and move at a speed of 70mm / s until the laser beam 5 moves along the processing trajectory. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com