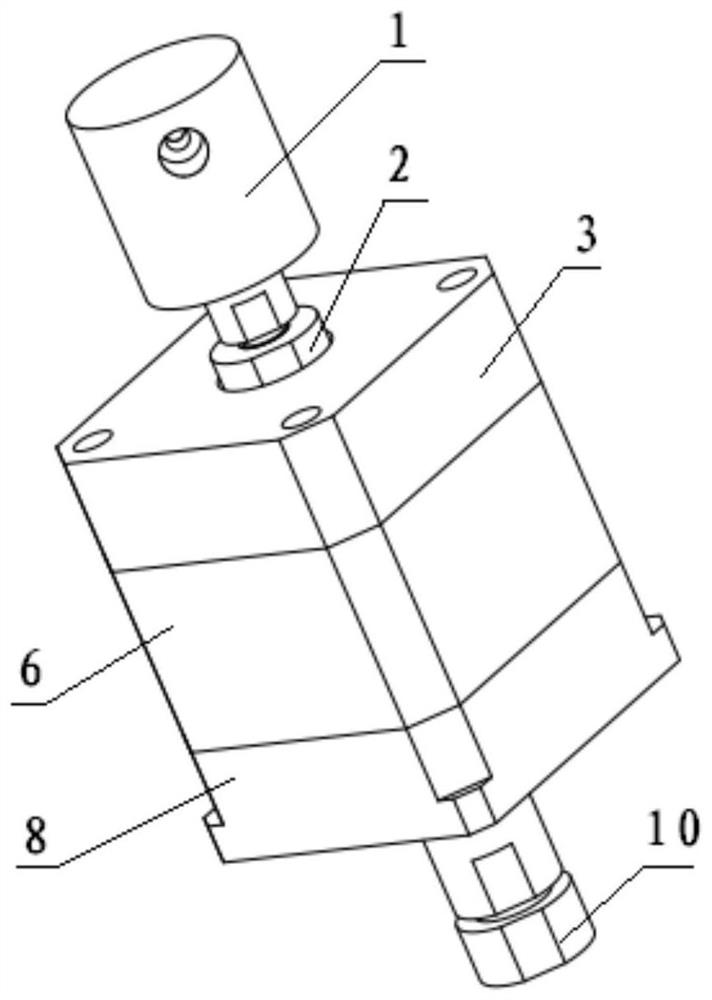

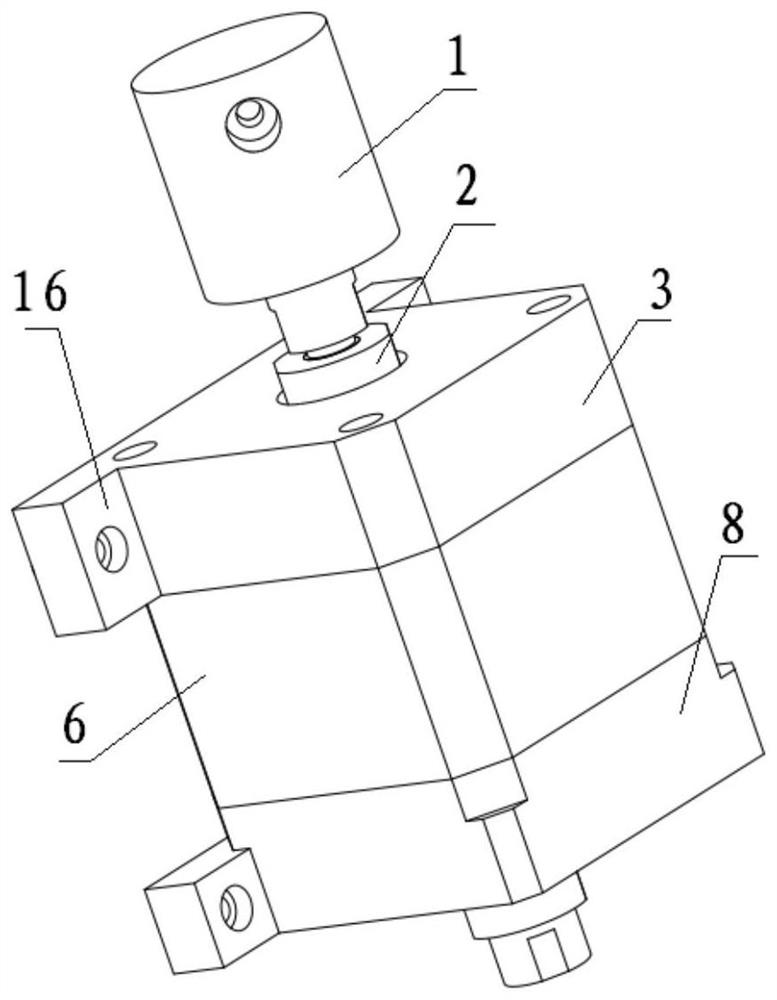

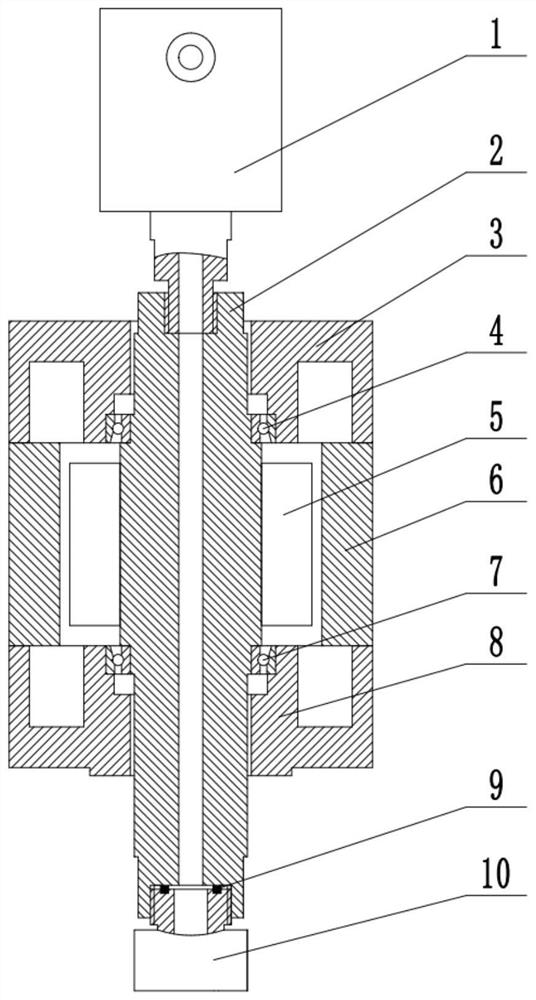

Rotating jet flow polishing device and method

A polishing device and jet technology, which is applied to used abrasive treatment devices, abrasives, metal processing equipment, etc., can solve the problems of low polishing efficiency and small removal function spots, so as to improve polishing efficiency, improve processing quality, and ensure The effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] In this embodiment, the rotary jet nozzle part 15 of the present invention can be installed on the multi-axis motion platform 13, and the motion platform 13 has three degrees of freedom of linear motion of X, Y, and Z and one around the A axis. rotational degrees of freedom, such as Figure 7 As shown, the jet nozzle part 15 is installed on the Z-axis slider of the motion platform 13 through the replacement device 14, and the workpiece to be processed is fixed on the workbench. The jet nozzle part 15 is driven by the Z-axis slider of the moving platform 13 and moved to a suitable position. The liquid supply system 11 transports the polishing liquid to the liquid collection chamber 102 of the polishing nozzle 10 through the liquid supply pipeline, and then passes through the jet nozzle hole 103 is sprayed onto the surface of the workpiece, and the polishing liquid jet rotates around its removal spots to form a Gaussian removal function. Through the rotational speed cont...

Embodiment 2

[0062] In this embodiment, the jet nozzle part 15 of the present invention can be installed on the mechanical arm of an industrial robot. As the end effector of the industrial robot, the rotating nozzle can adjust the distance between the nozzle and the surface of the workpiece and the relative posture of the nozzle and the workpiece by controlling the movement of the mechanical arm. When polishing the workpiece, it is necessary to plan the movement trajectory of the mechanical arm in advance and generate the CNC machining program. The liquid supply system delivers the polishing liquid to the rotating nozzle through the liquid supply pipeline. Driven by the mechanical arm, it is sprayed onto the surface of the workpiece, which can be used for complex curved surfaces. for polishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com