Automatic injection molding system and control method thereof

An automatic injection molding and injection molding system technology, applied in the direction of manufacturing tools, feeding devices, positioning devices, etc., can solve problems such as low automation, low production efficiency, and injection molding process errors, achieve excellent punching performance and save labor costs , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

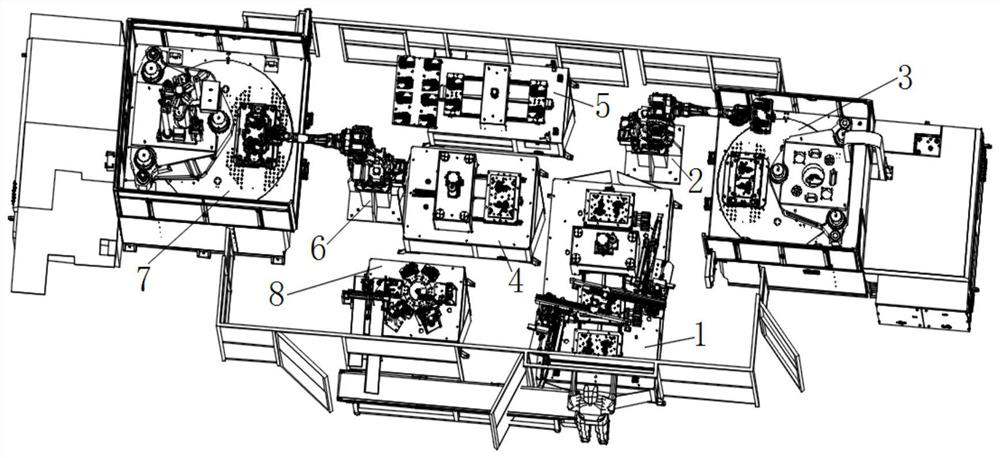

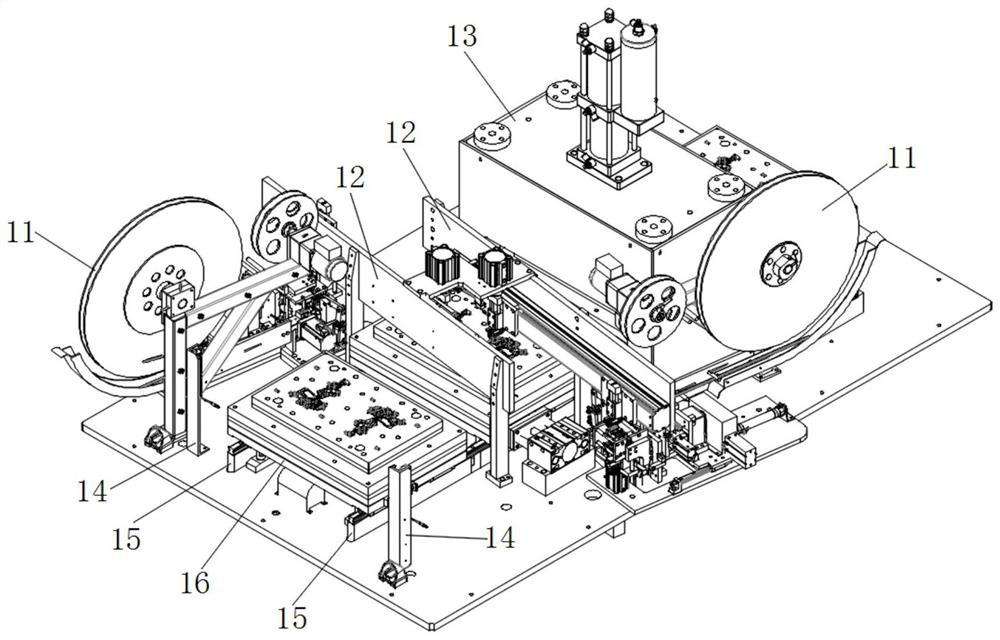

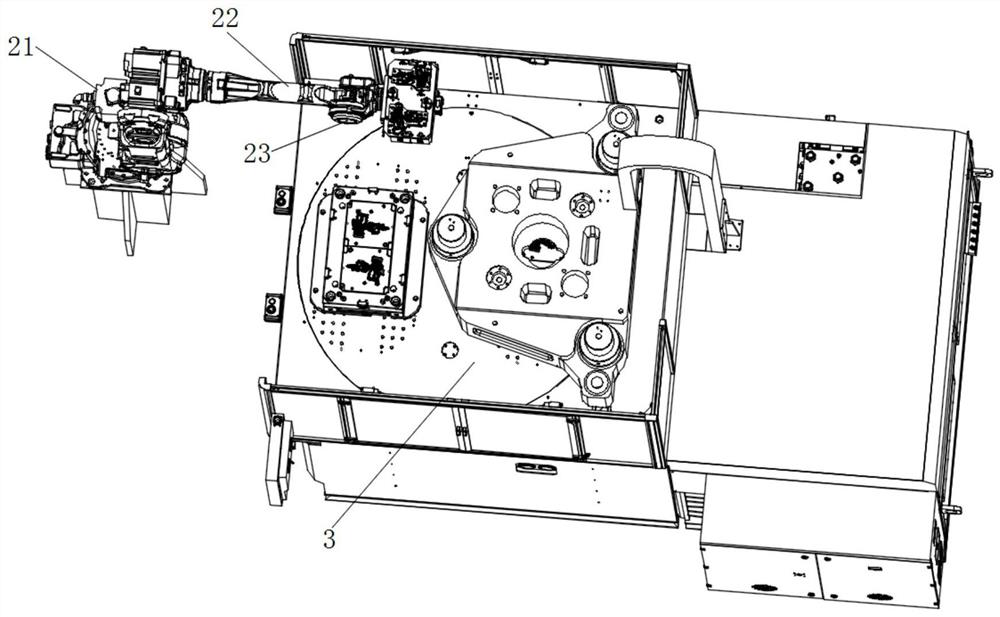

[0040] An automatic injection molding system, including a first punching device 1, a first pick-and-place device 2, a first injection device 3, a second punching device 4 and a first testing device 5, the first punching device 1 is used for punching Cut the metal parts to be processed, the first pick-and-discharge device 2 is used to transfer the metal parts, and the metal parts pass through the first pick-and-discharge device 2 from the first punching device 1 to the first injection molding device 3 and the second punching device 4 and the first testing device 5, the second punching device 4 is used to process the part of the punched metal piece that is not punched by the first punching device 1, the first punching device 1, the first injection molding device 3, the second The punching device 4 and the first testing device 5 surround the first pick-and-discharge device 2, thereby improving the moving efficiency of the first pick-and-discharge device 2, and the metal piece pass...

Embodiment 2

[0054] A control method for an automatic injection molding system, comprising the following steps:

[0055] S1. Place the metal piece to be processed in the first punching device 1, and the first punching device 1 punches and processes the metal piece;

[0056] S2. The first loading and unloading device 2 transfers the punched metal parts from the first punching device 1 to the first injection device 3, and the first injection device 3 injects the punched metal parts;

[0057] S3. The first pick-and-place device 2 transfers the injected metal parts from the first injection device 3 to the second punching device 4, and the second punching device 4 punches the injected metal parts to form the metal parts to be formed. Check metal parts;

[0058] S4. The first pick-and-place device 2 transfers the metal piece to be inspected from the second punching device 4 to the first testing device 5, and the first testing device 5 detects the quality of the metal piece to be inspected.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com