Molding system for fully degradable biomass agricultural film production

A fully degradable, biomass-based technology, applied in applications, plant protection, plant protection covers, etc., can solve the problems of easy tearing, damage, low efficiency, etc., and achieve the effect of realizing adjustment and eliminating tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

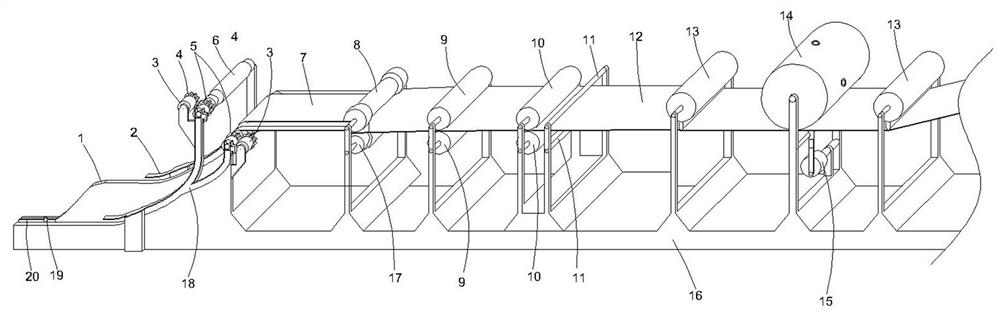

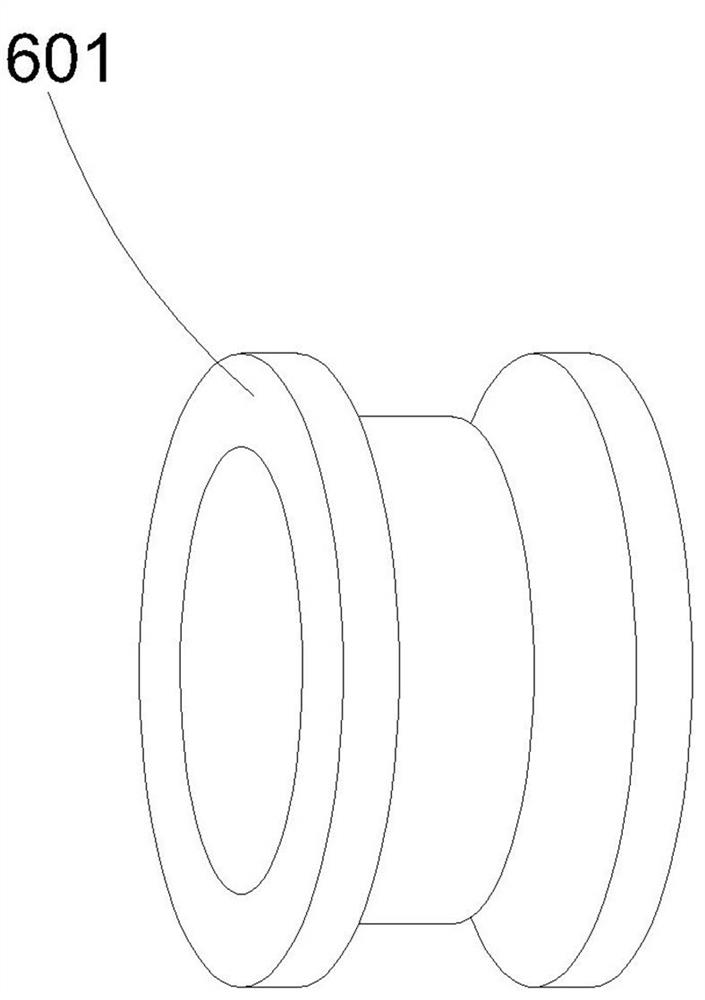

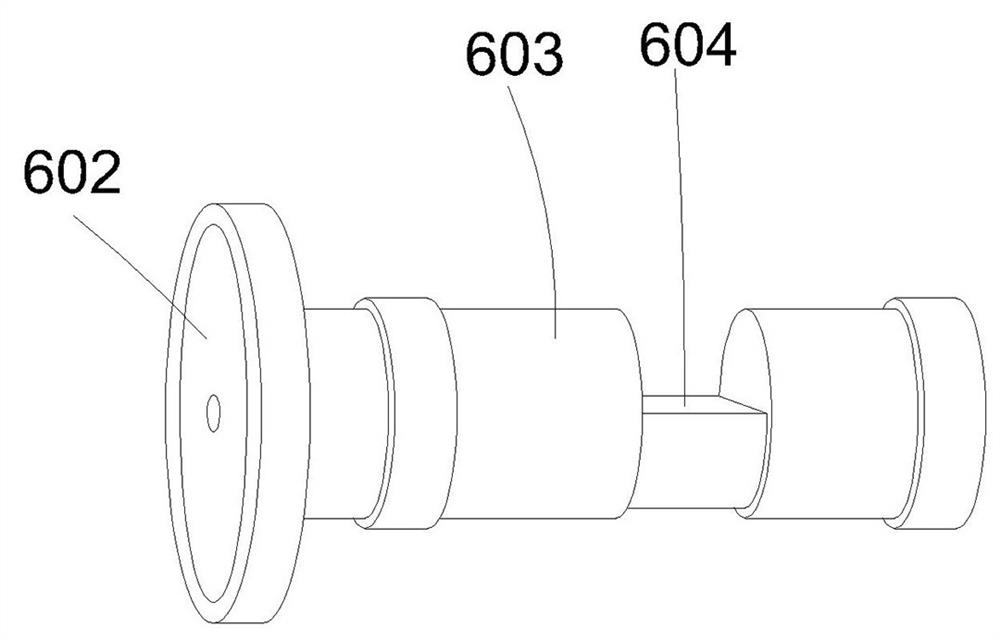

[0043] The forming system for the production of fully degradable biomass agricultural film, its structure is as follows Figure 1-Figure 13 shown, where figure 1 The rotary motor, the creasing motor and the crimping motor are not shown, including the forming frame 16 and the winding frame 2. The forming frame 16 is provided with an indentation device, and one side of the indentation device is provided with a screw that is fixed on the forming frame 16. The drug application device, the side of the drug application device away from the indentation device is provided with a crimping device fixed on the forming frame 16, and the side of the crimping device away from the drug applicator is provided with a winding device that matches the winding frame 2 The edge-holding device includes an agricultural film holder, and the side of the agricultural film holder away from the pesticide application device is provided with an agricultural film edge holder; the agricultural film holder inc...

Embodiment 2

[0052] The forming system for the production of fully degradable biomass agricultural film, its structure is as follows Figure 14 As shown, the difference from Embodiment 1 is that the agricultural film reel 6 is provided with an agricultural film pressing device that is rotatably connected with the winding frame 2 through the pressing rotating shaft 2103, and the agricultural film pressing device includes an agricultural film pressing device that is connected with the winding frame 2. The movable bracket 2102 that is movably connected, the end of the movable bracket 2102 away from the winding frame 2 is provided with a pressure roller 2101 that is rotatably connected with the movable bracket 2102, and the movable bracket 2102 is provided with a compression spring that is fixedly connected with the indentation frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com