Method for preparing nano copper oxide by microwave hydrothermal method and application of nano copper oxide

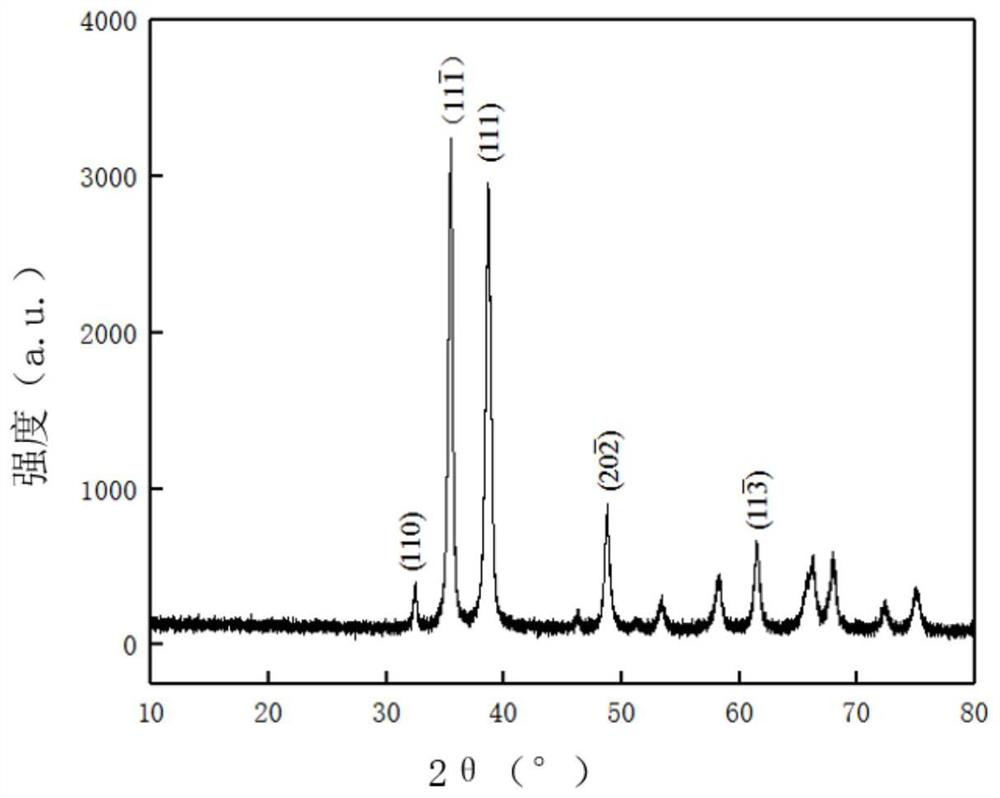

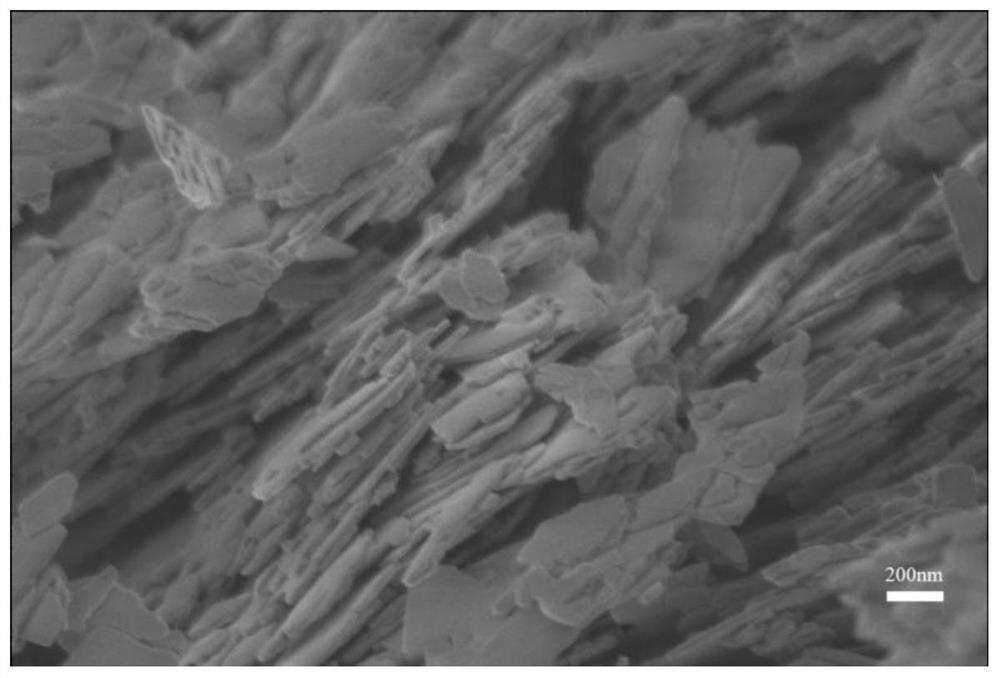

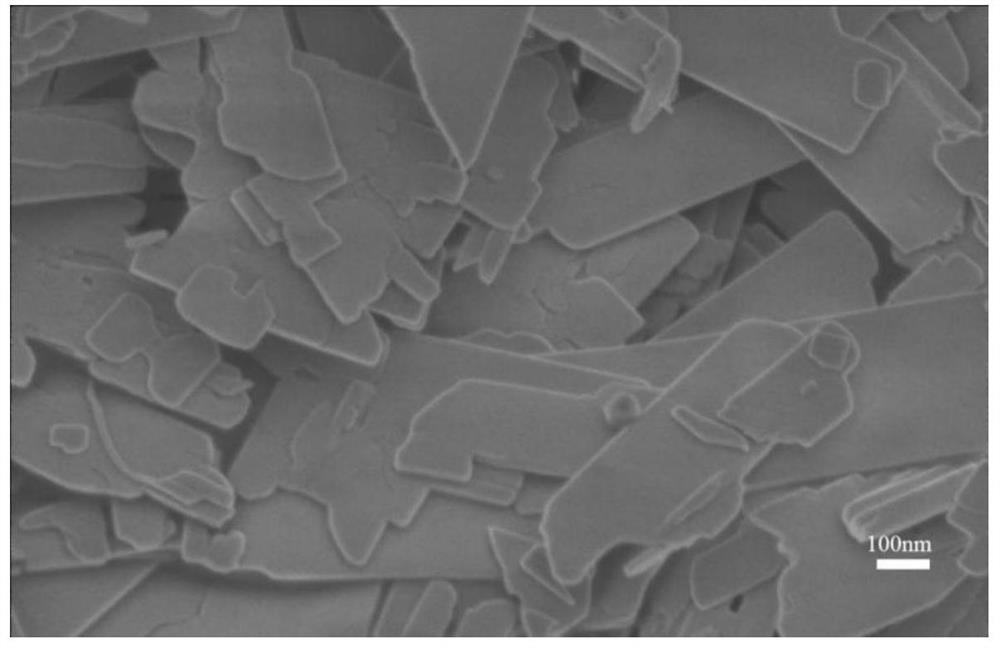

A technology of nano-copper oxide and microwave hydrothermal method, which is applied in the field of nano-materials, can solve the problems of large size and structure of copper oxide, poor adsorption effect of organic dyes, uneven heating, etc., and achieve better crystallinity and better adsorption effect , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing nano-copper oxide by microwave hydrothermal method, comprising the steps of:

[0031] (1) Weigh copper chloride dihydrate and sodium hydroxide according to the molar ratio of 1:10, dissolve them in 5mL deionized water until completely dissolved, form copper chloride aqueous solution and sodium hydroxide solution, and oxidize the above hydroxide under stirring The sodium solution is added dropwise in the above copper chloride aqueous solution to obtain the precursor copper hydroxide mixed solution;

[0032] (2) After transferring the precursor copper hydroxide mixed solution to the lining of the microwave hydrothermal reaction kettle, install it in a microwave reactor for microwave hydrothermal reaction. The reaction conditions are pressure 4MPa, power 1000W, and sintering at 120°C for 24min , cooled to room temperature after the reaction; washed three times with deionized water and three times with ethanol, then dried in an oven at 70°C to obtain ...

Embodiment 2

[0036] A method for preparing nano-copper oxide by microwave hydrothermal method, comprising the steps of:

[0037] (1) Weigh copper acetate monohydrate and sodium hydroxide according to the molar ratio of 1:30, dissolve them in 5mL deionized water until completely dissolved, form copper acetate aqueous solution and sodium hydroxide solution, and dissolve the above sodium hydroxide solution under stirring Add dropwise in above copper acetate aqueous solution, obtain precursor copper hydroxide mixed solution;

[0038] (2) After transferring the precursor copper hydroxide mixed solution to the lining of the microwave hydrothermal reaction kettle, install it in a microwave reactor for microwave hydrothermal reaction. The reaction conditions are pressure 4MPa, power 1000W, and sintering at 120°C for 48min. , cooled to room temperature after the reaction; washed three times with deionized water and three times with ethanol, then dried in an oven at 60°C to obtain nano-copper oxide....

Embodiment 3

[0041] A method for preparing nano-copper oxide by microwave hydrothermal method, comprising the steps of:

[0042] (1) Weigh copper sulfate pentahydrate and sodium hydroxide according to the molar ratio of 1:10, dissolve them in 5mL deionized water until completely dissolved, form copper sulfate aqueous solution and sodium hydroxide solution, and mix the above sodium hydroxide solution with stirring Add dropwise to the above copper sulfate aqueous solution to obtain the precursor copper hydroxide mixed solution;

[0043] (2) After transferring the precursor copper hydroxide mixed solution to the lining of the microwave hydrothermal reaction kettle, install it in a microwave reactor for microwave hydrothermal reaction. The reaction conditions are pressure 4MPa, power 1000W, sintering at 150°C for 24min , cooled to room temperature after the reaction; washed three times with deionized water and three times with ethanol, then dried in an oven at 80°C to obtain nanometer copper o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap