Electromagnetic coil cooling water making machine

An electromagnetic coil and cooling water technology, which is applied in water/sewage treatment, water treatment parameter control, heating water/sewage treatment, etc., can solve the problems of low water production efficiency, high cost, and reduced electrical conductivity, etc., and achieve saving filter use Controllable raw materials and electrical conductivity, high water production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

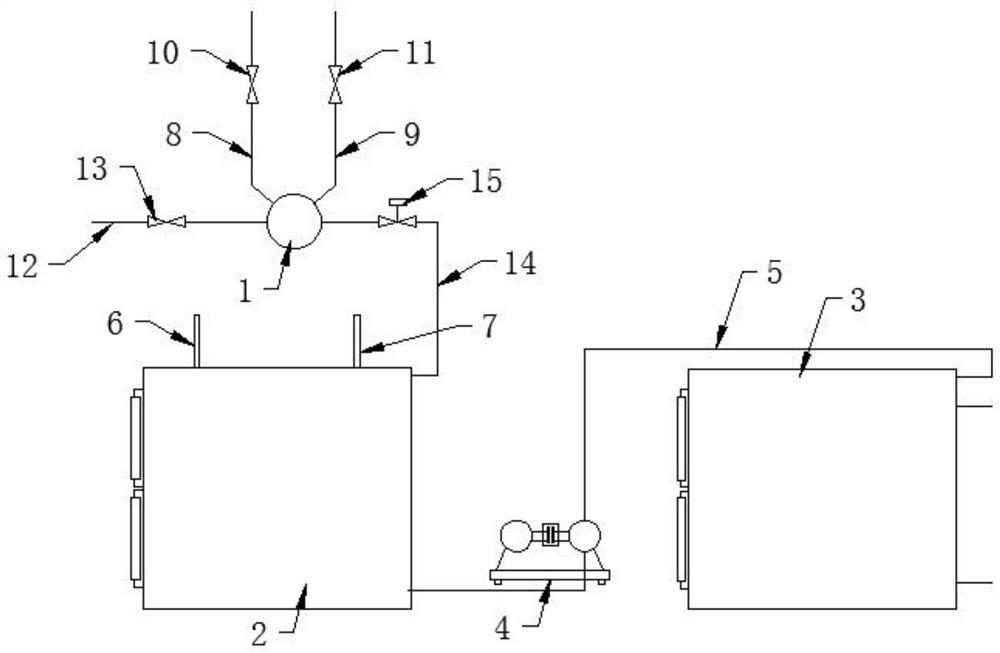

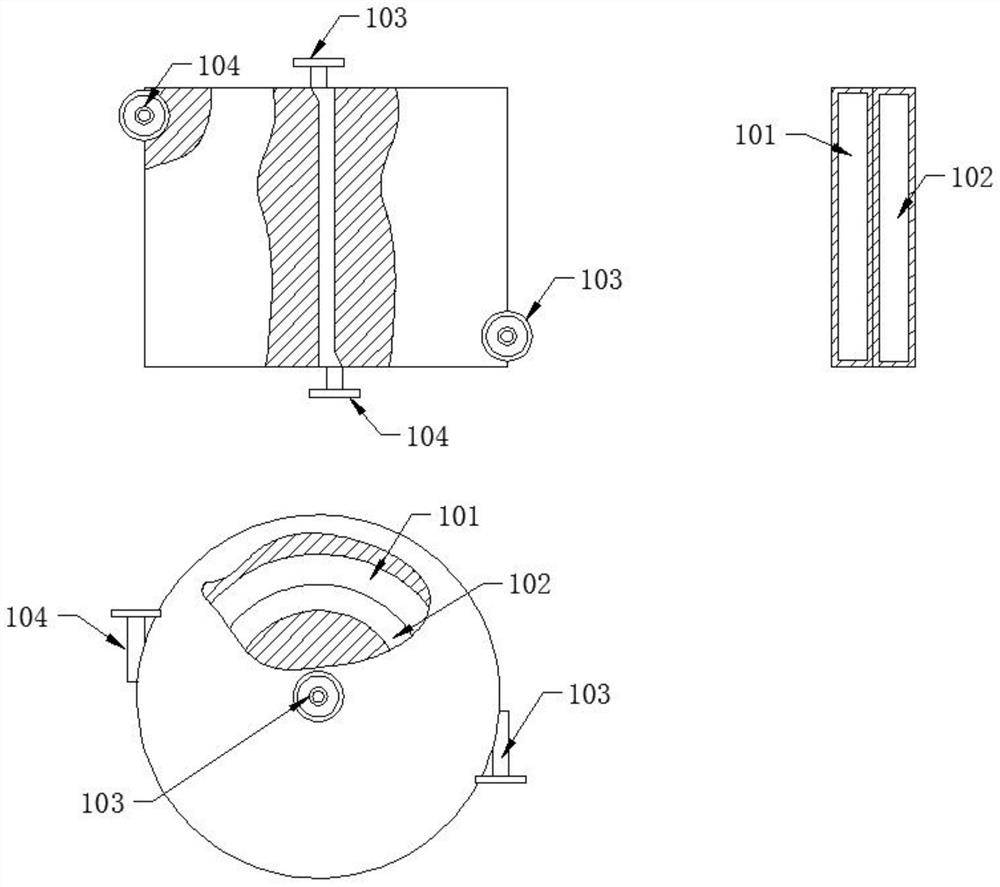

[0017] see Figure 1-2 , the present invention provides a kind of technical scheme: electromagnetic coil cooling water water making machine, comprise heat exchange device 1, distilled water making water tank 2 and distilled water tank 3, the bottom water outlet of distilled water making water tank 2 passes water pump 4 and water delivery pipe 5 and distilled water The top water inlet of tank 3 is connected. The heat exchange device 1 includes hollow channel 1 101 and hollow channel 2 102 inside and flange 1 103 and flange 2 104 outside. The two flanges 103 are respectively connected to the water inlet pipes. 8 and the water outlet pipe 9, the water inlet pipe 8 and the water outlet pipe 9 are provided with a water inlet valve 10 and a water outlet valve 11, and two flanges 104 are respectively connected to the steam inlet pipe 12 and the distilled water pipe 14, and the steam inlet pipe 12 and the distilled water pipe 14 Air intake valve 13 and water delivery valve 15 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com