Heating parameter setting method capable of clearly considering structure target requirements

A technology with goals and organization, applied in the direction of heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve the problem of inability to provide specific heating parameters, and achieve the effect of strong adaptability

Active Publication Date: 2020-11-06

XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to overcome the shortcomings of the above-mentioned prior art, and provide a method for formulating heating parameters that clearly considers the requirements of organizational goals. This method solves the technical problem that specific heating parameters cannot be provided for steel types with different alloy elements in the prior art.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0043] Exemplary embodiments of the present invention will be described in detail below through specific examples. The following example takes 07MnNiMoDR steel as an example, but the present invention is not limited thereto, and the heating process of other materials can also be formulated through the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

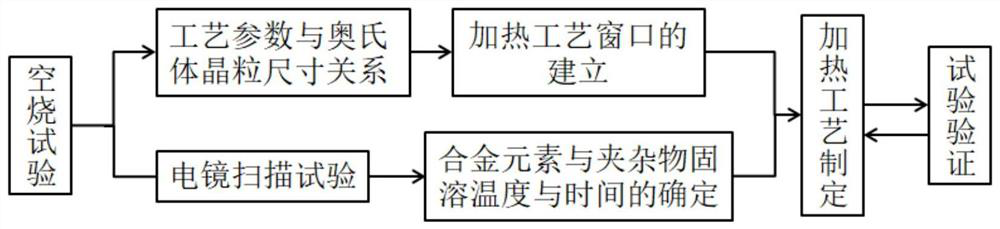

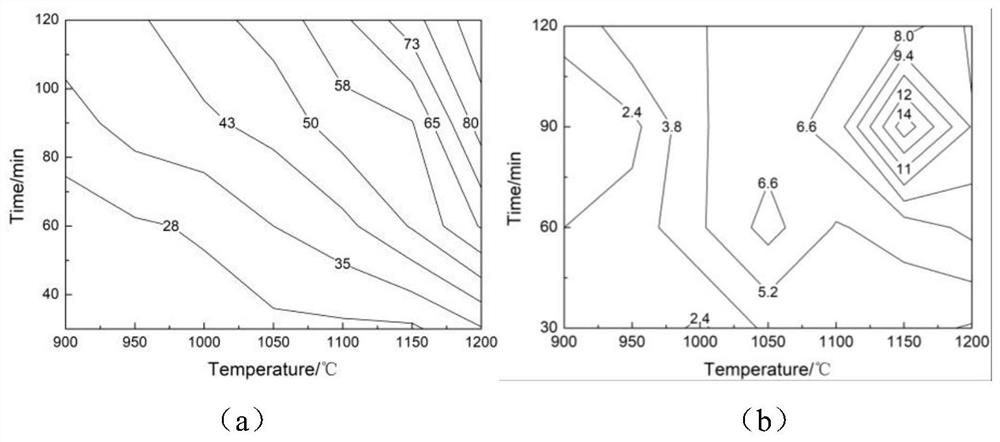

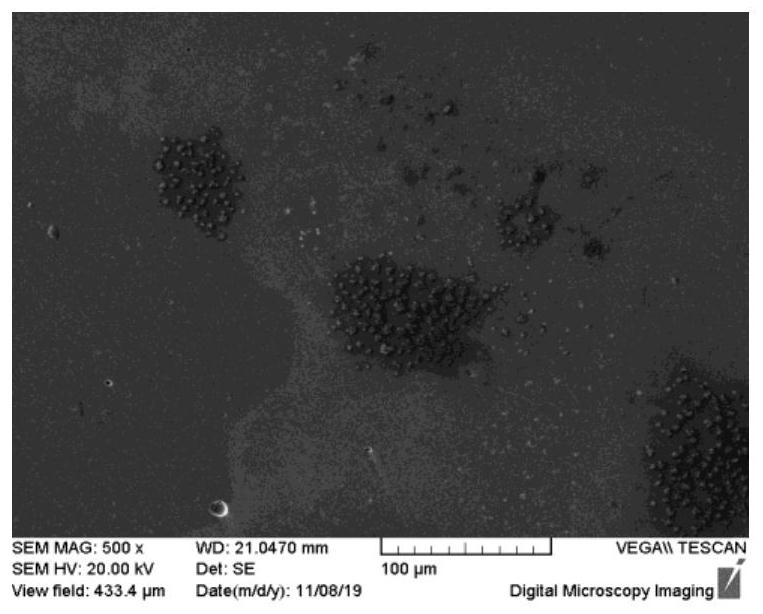

The invention discloses a heating parameter setting method capable of clearly considering structure target requirements. The heating parameter setting method capable of clearly considering the structure target requirements comprises the following steps that firstly an empty burning sample is obtained by aiming at a target steel grade, the lower limits of heating temperature and heating time are obtained by combining the austenite structure grain sizes of the empty burning sample in austenite structure grain pictures, and the heating temperature and the heating time are further restrained by taking the dissolution condition of inclusions as a standard, so that the reasonable heating time of the target steel grade is obtained; and a reasonable heating process is formulated according to the requirement of a material, the structure change of the material in the heating process is accurately controlled, the reasonability of the heated blank structure is guaranteed, and resource utilizationis maximized. According to the method, the dissolution condition of the inclusions in the material along with the heating temperature and the heat preservation time can be obtained according to the size change of the inclusions at different times, a reasonable heating process can be formulated according to the field condition requirements, and resource utilization is maximized.

Description

【Technical field】 [0001] The invention belongs to the technical field of material processing, and in particular relates to a method for formulating heating parameters that clearly considers organizational target requirements. 【Background technique】 [0002] At present, in the steel mills, the formulation of the heating process in the thermal processing of materials is generally based on empirical formulas to calculate the heating time, and the determination of the heating temperature is generally determined according to the dissolution temperature of the alloy elements of the steel type. This method has great disadvantages Defective. When the type and content of alloying elements in the material change, its solution temperature and solution time will change accordingly. The heating process formulated only by empirical formulas cannot accurately predict the uniformity of the grain size after heating. Understanding the evolution of material structure with process parameters a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21D1/34C21D11/00

CPCC21D1/34C21D11/00

Inventor 庞玉华

Owner XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com