Patents

Literature

33results about How to "Resource maximization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

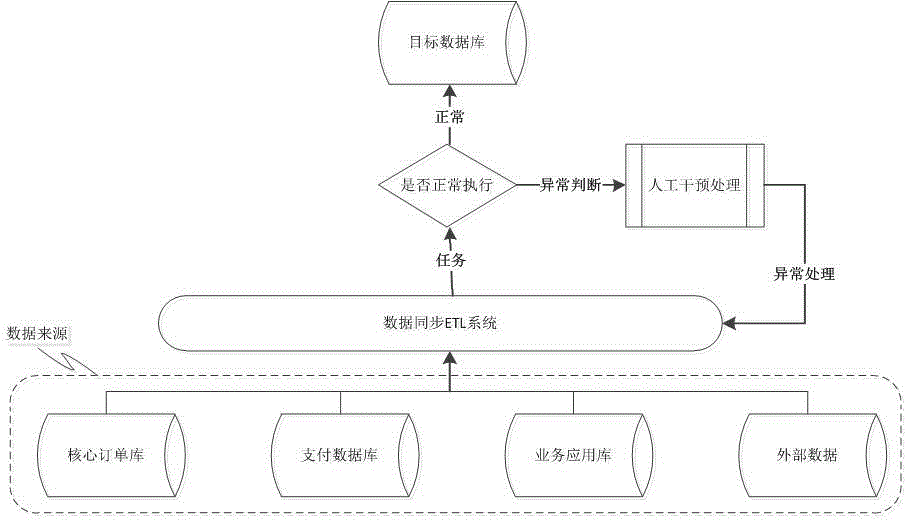

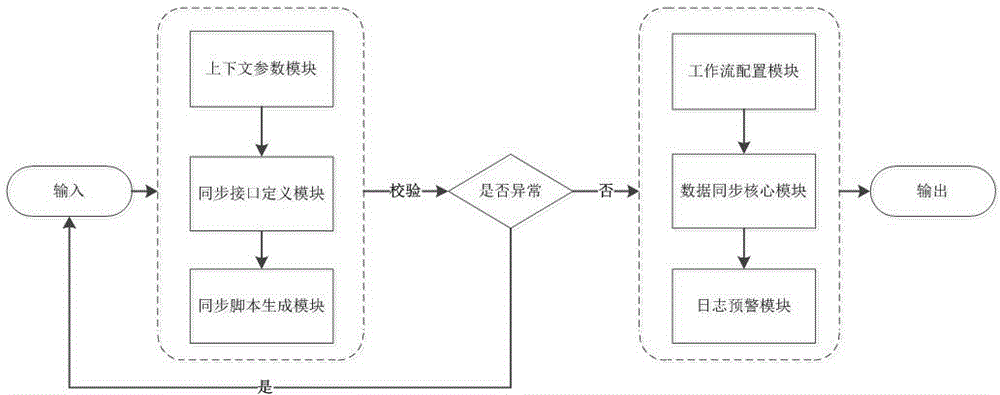

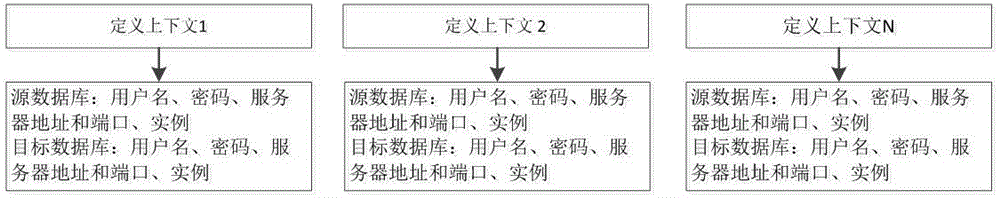

Data synchronism ETL (Extract Transform Load) system

ActiveCN104317843AReduce waiting timeTake advantage ofDatabase distribution/replicationSpecial data processing applicationsMultiple contextData synchronization

The invention belongs to the technical field of data synchronism, and particularly discloses a data synchronism ETL (Extract Transform Load) system. The data synchronism ETL system comprises the following function modules: a context parameter configuration module, a synchronous interface definition module, a synchronous script generation module, a workflow configuration module, a data synchronism core module and a log and prewarning module, wherein the context parameter configuration module, the synchronous interface definition module and the synchronous script generation module are basic modules and are operated according to the sequence of the modules to generate a script; the workflow configuration module mainly plays the role of a dispatching center, and configures the script in a workflow to realize parallel or serial execution, parallel progress amount, and what time or condition a task is triggered; when anomaly or an error task occurs in the execution steps, the log and prewarning module captures an error reason, and informs system management personnel of the error reason. The data synchronism ETL system is provided with a bidirectional synchronism mechanism, and is capable of supporting data sources configured with multiple context names and accessing multiple environments, the coverage of the synchronism method is wide, meanwhile, a complicated user-defined synchronism method is supported, and the expansibility is stronger.

Owner:SHANGHAI HANDPAL INFORMATION TECH SERVICE

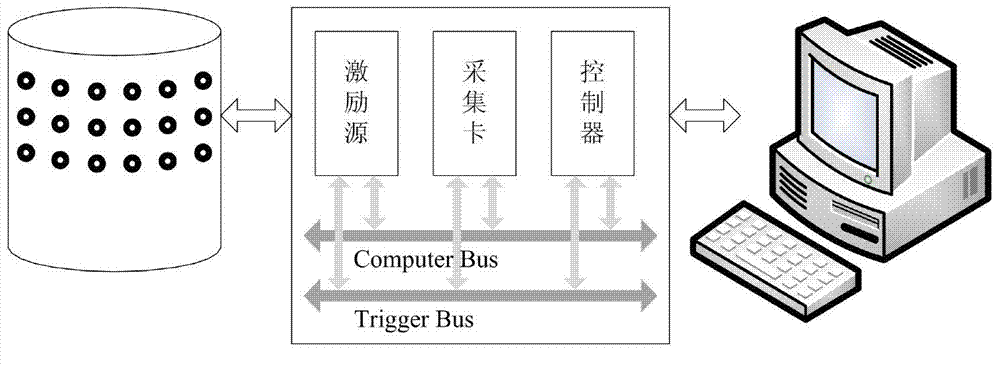

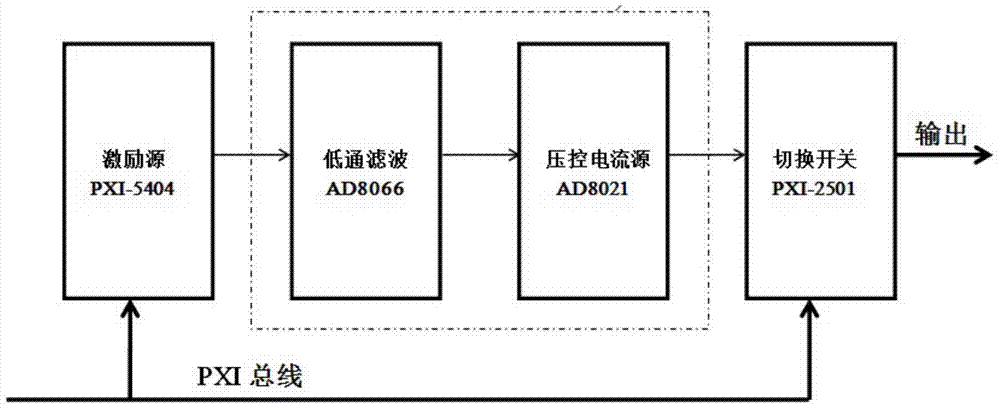

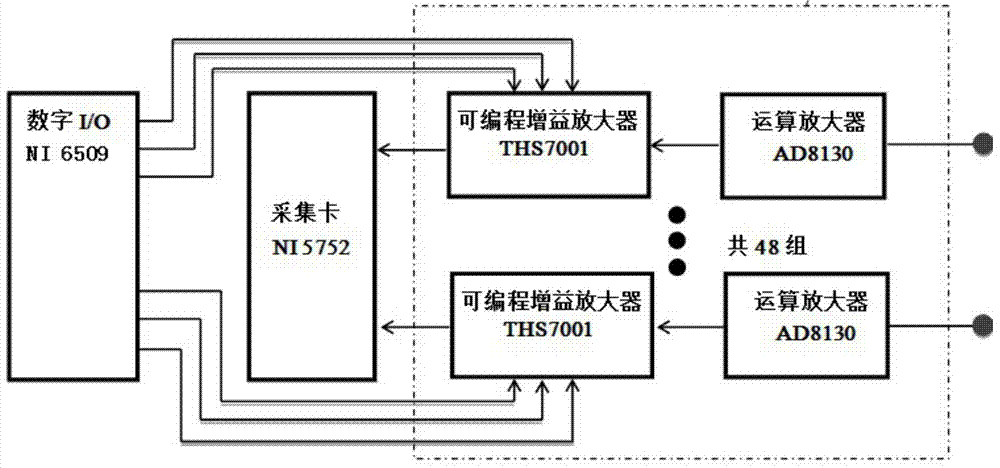

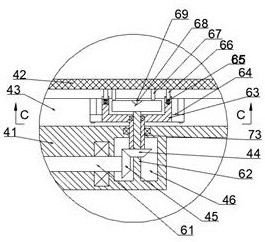

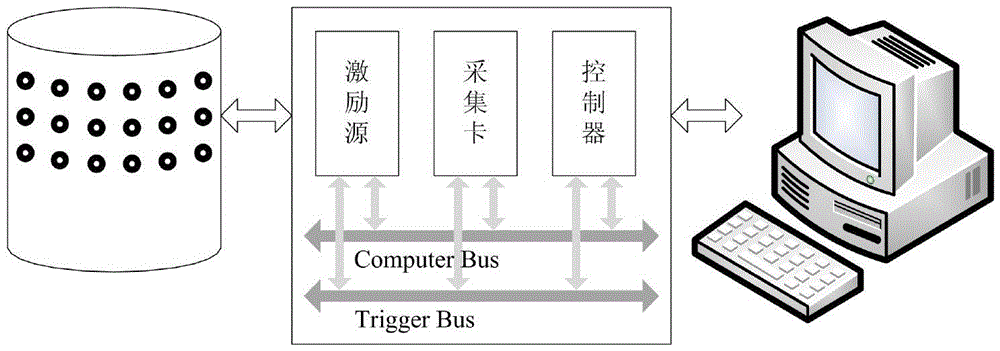

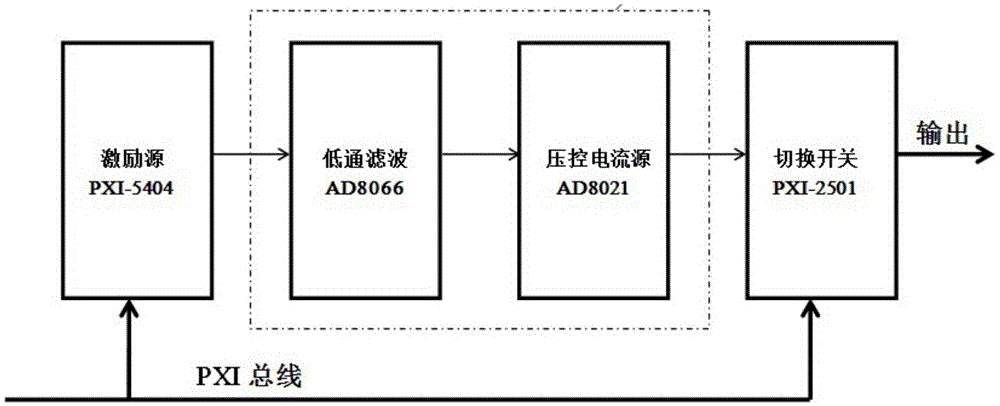

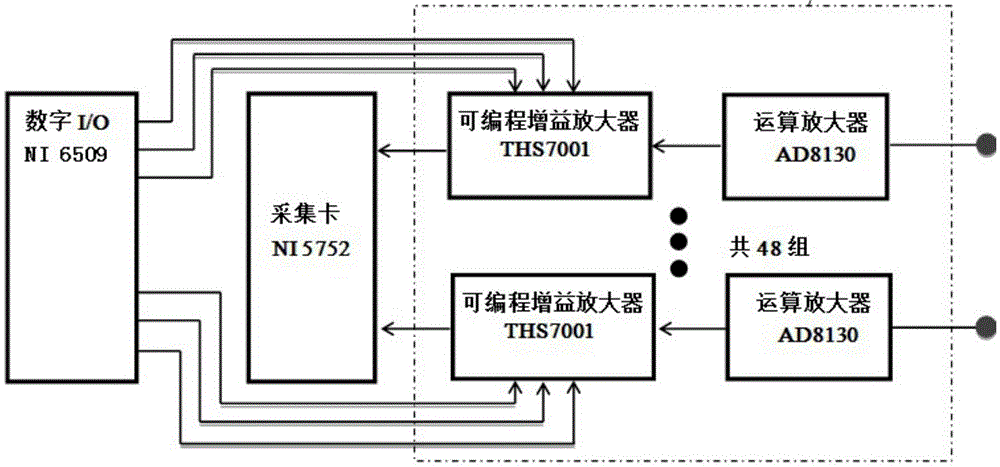

PXI-bus-based respiration process three-dimensional electrical impedance imaging system and imaging method thereof

InactiveCN103690166AAvoid time costReduce maintenance costsDiagnostic recording/measuringSensorsSignal onFiltration

The invention relates to a PXI-bus-based respiration process three-dimensional electrical impedance imaging system and an imaging method thereof. According to the PXI-bus-based respiration process three-dimensional electrical impedance imaging system and the imaging method thereof, the three-dimensional electrical impedance imaging system which is in three layers and comprises 48 electrodes is constructed by means of highly integrated hardware and software tool kits of the PXI bus; a pair of adjacent exciting electrodes is selected sequentially through a gating switch; safe alternating currents are injected into a thoracic cavity, voltage signals on the other electrodes are collected synchronously; a distribution image of sensitive areas of electrical impedances inside the thoracic cavity during a respiration process is obtained on a computer through filtration, amplification, analog-digital conversion, demodulation and transmission and finally through an image reconstruction algorithm. Compared with the existing electric resistance imaging system, the PXI-bus-based respiration process three-dimensional electrical impedance imaging system has the advantages of being high in measuring accuracy, rapid in speed and high in reliability, having no damage to human bodies, achieving continuous real-time bedside monitoring and continuously monitoring respiration variations of human lungs clinically in real time.

Owner:TIANJIN UNIV OF SCI & TECH

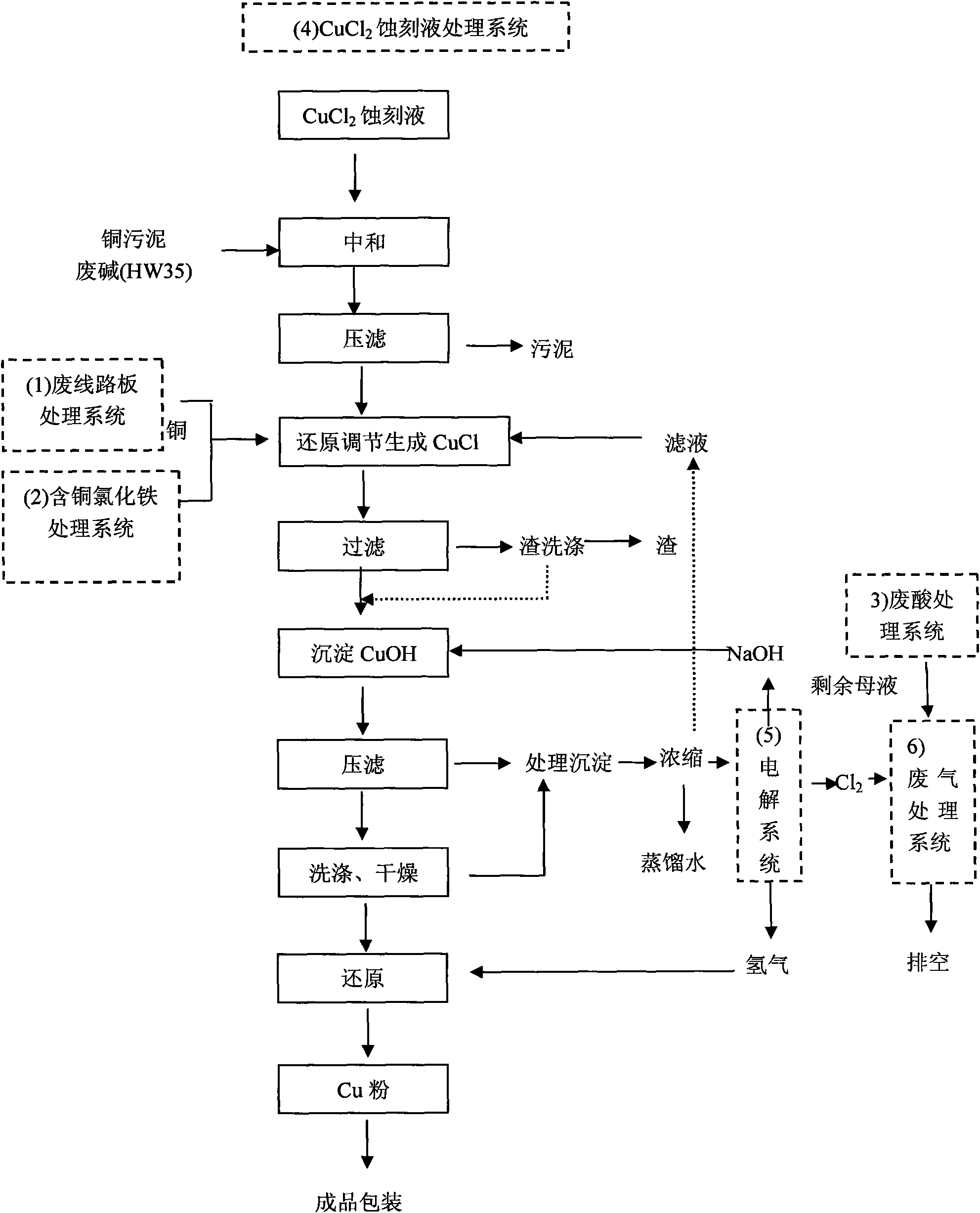

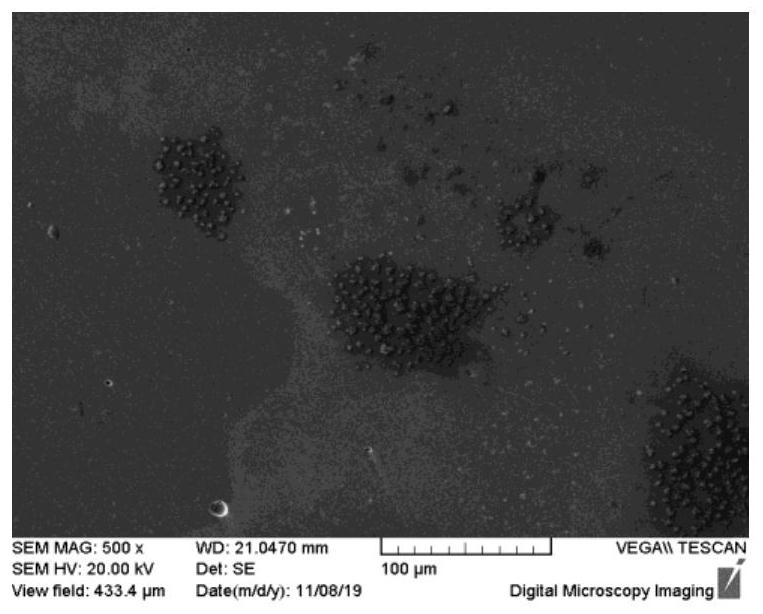

Technology for extracting copper powder from waste materials generated in circuit board manufacturing plants by compound extraction method

InactiveCN101658941ASolve processing problemsEnhance the right to speakProcess efficiency improvementElectrolysisMature technology

The invention relates to a technology for extracting copper powder from waste materials generated in circuit board manufacturing plants by a compound extraction method, belonging to the technical fields of electronic product recovery, comprehensive utilization and environment protection. In the invention, the technology is divided into six sets of subsystems, namely a waste circuit board processing system, a copper-bearing ferric chloride processing system, a waste acid processing system, a CuCl2 etching solution processing system, a system for producing hydrogen by electrolysis and a waste gas processing system. The invention can simultaneously process waste circuit boards (HW49), CuCl2 etching solution (HW22), copper-bearing ferric chloride (HW22), waste alkali (HW35) and waste acid (HW34), and combines several sets of processing technologies in which the products are used as raw materials mutually, thereby saving the investment. The processing systems are contained in one technology, thereby solving the problem of the processing of most of hazardous wastes of heavy metals in an electronic plant. The product quality reaches or exceeds the level of electrolytic copper, each unit system in the technology for extracting copper powder is a mature technology, the used equipment is prototype equipment, and the initial investment is less. Moreover, the problem of harm to environment, human bodies and ecology by hazardous wastes is solved, and the natural environment is effectively protected.

Owner:无锡金品环境技术有限公司

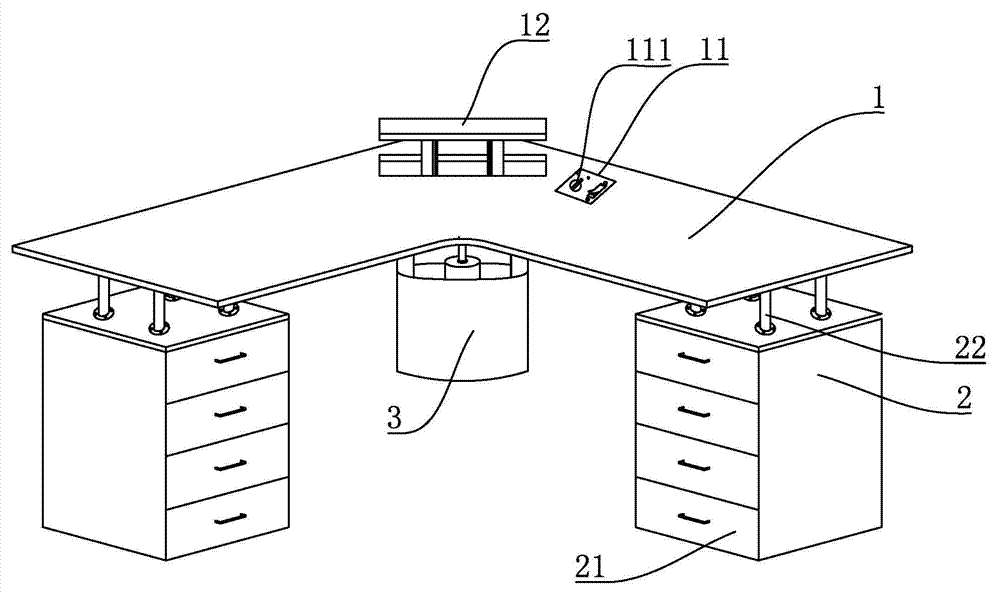

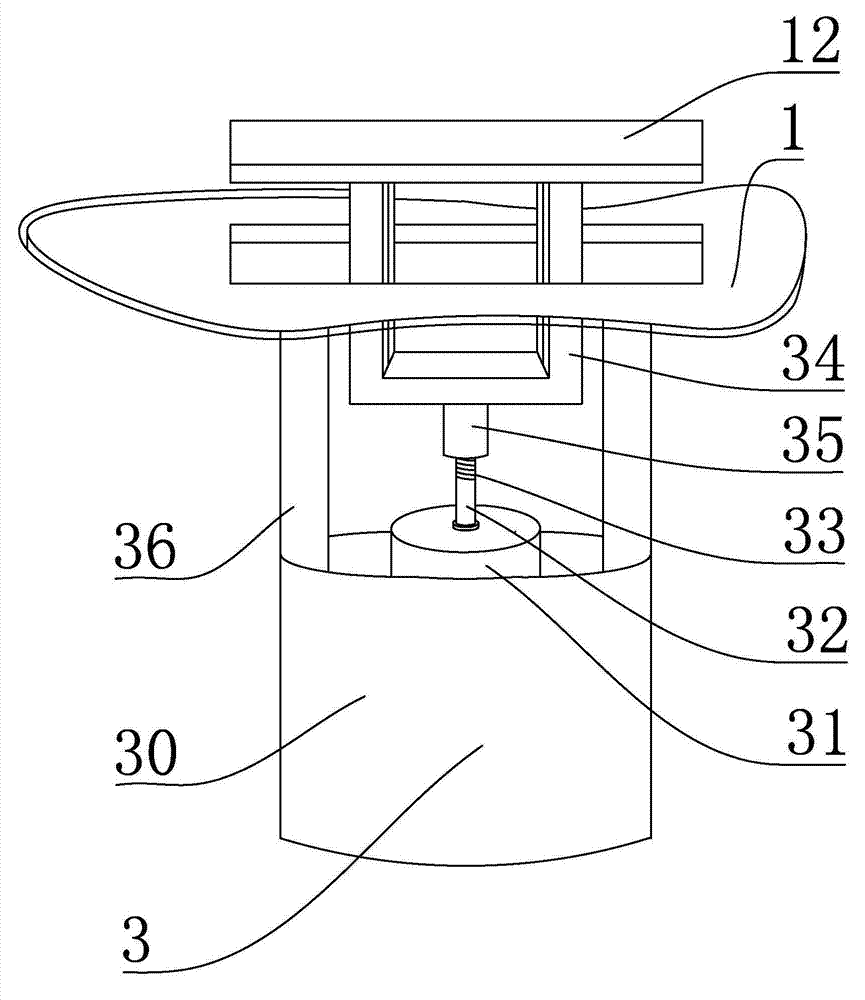

Lifting computer office table

InactiveCN104257104AImprove stabilityTo achieve the effect of height adjustmentOffice tablesFeetDisplay deviceLumbar

The invention discloses a lifting computer office table which comprises a tabletop and a lifting device. The table top is of an L-shaped tabletop structure. Two cabinets which are connected with the bottom of the tabletop through support ejection rods are arranged below two sides of the tabletop. The lifting device is arranged at the rear end of the tabletop and comprises a lifting base, a lifting hydraulic oil cylinder and a lifting bracket. The lifting base is provided with a base support column, the top of the base support column is connected with the bottom face of the tabletop, a display support plate is arranged at the top of the lifting bracket, the lifting hydraulic oil cylinder is fixedly embedded in the lifting base, the top end of a beam hanger is connected with the bottom of the lifting bracket, the corresponding positions of the tabletop and the display bracket are hollow to enable the display support plate to move up and down in the tabletop. A display can be effectively and quickly lifted and lowered to the proper height according to the requirements of operators, the working efficiency is improved, and the fatigue degree of movable joints such as lumbar vertebra and cervical vertebra of the operators is reduced.

Owner:南宁市磁汇科技有限公司

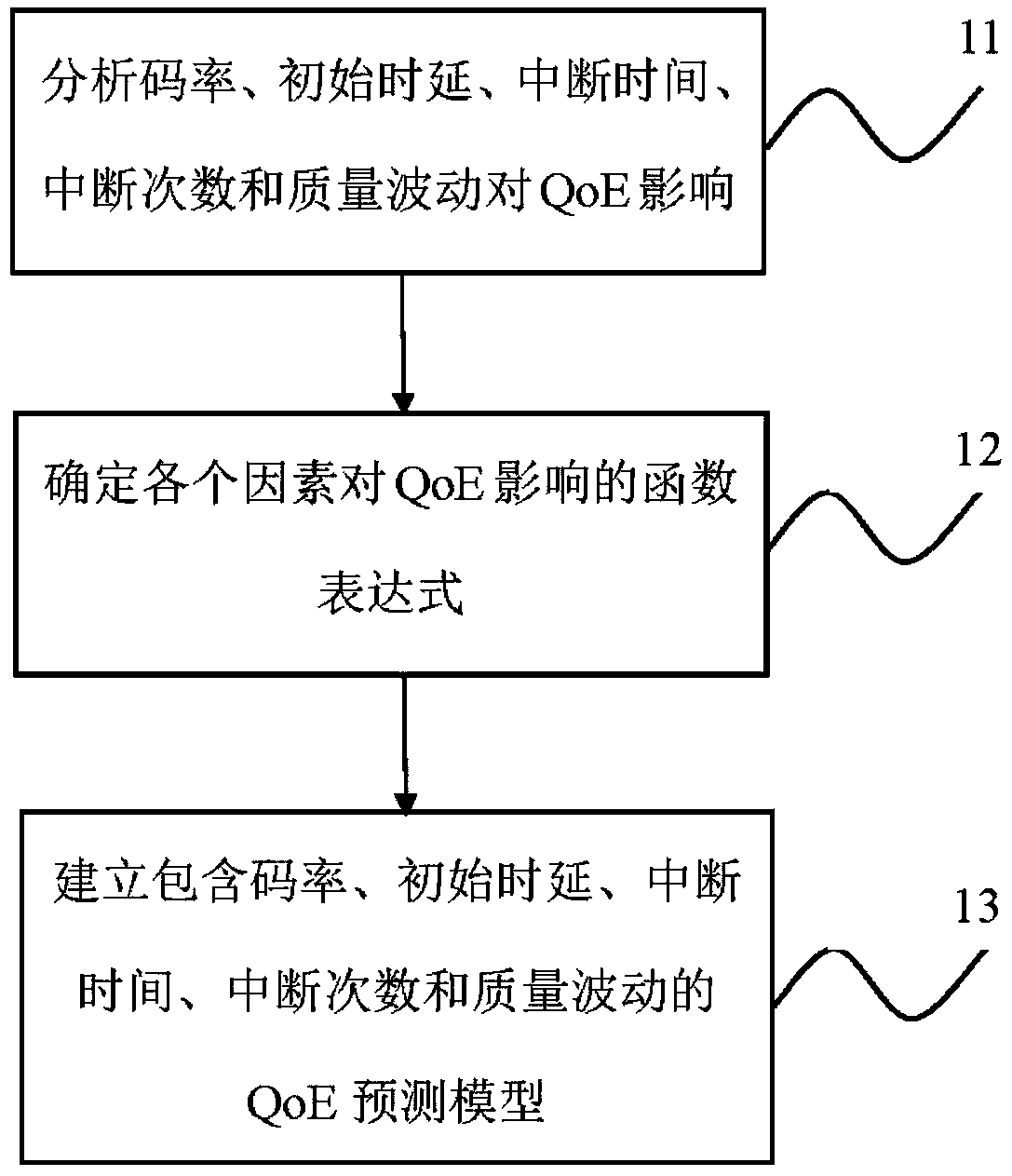

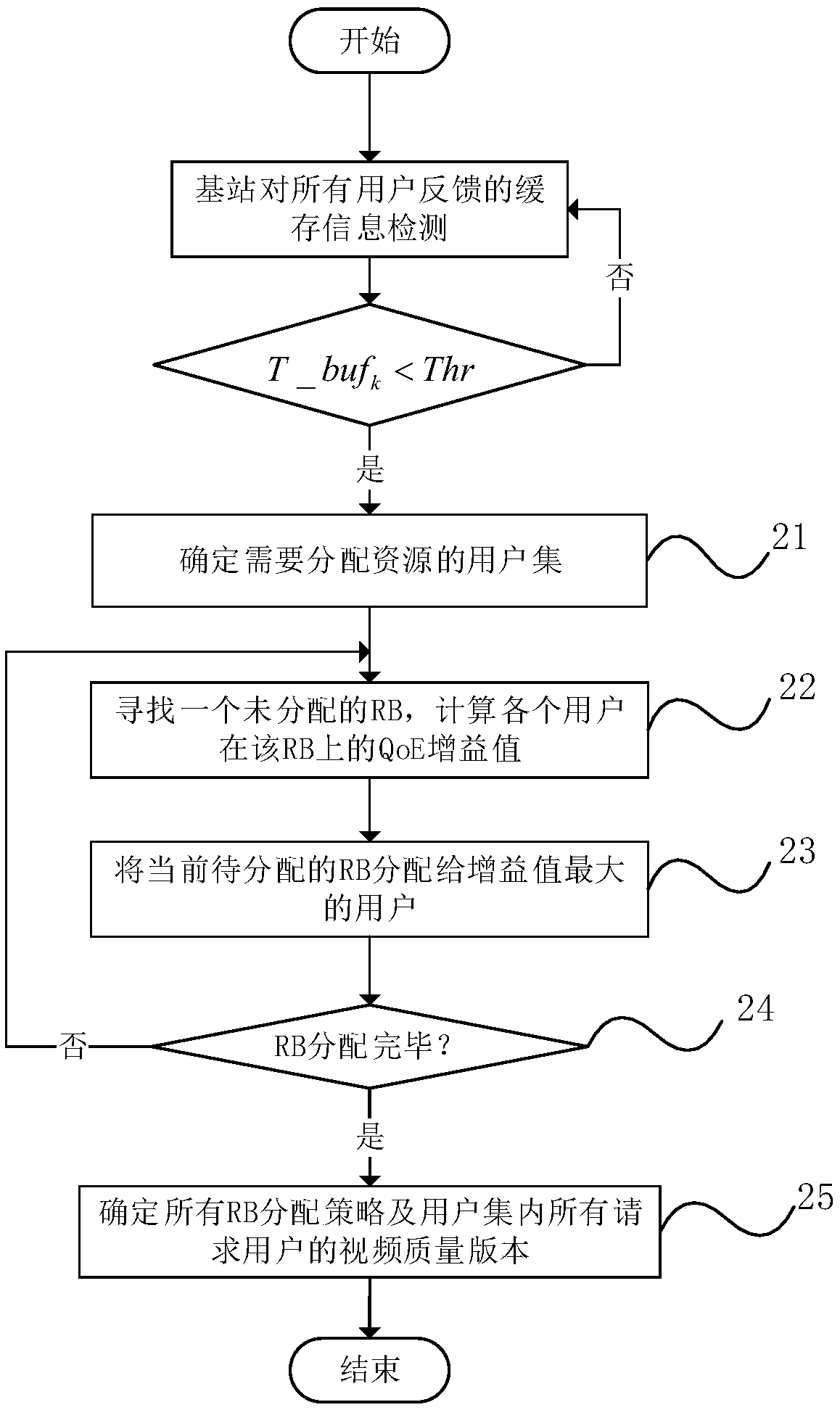

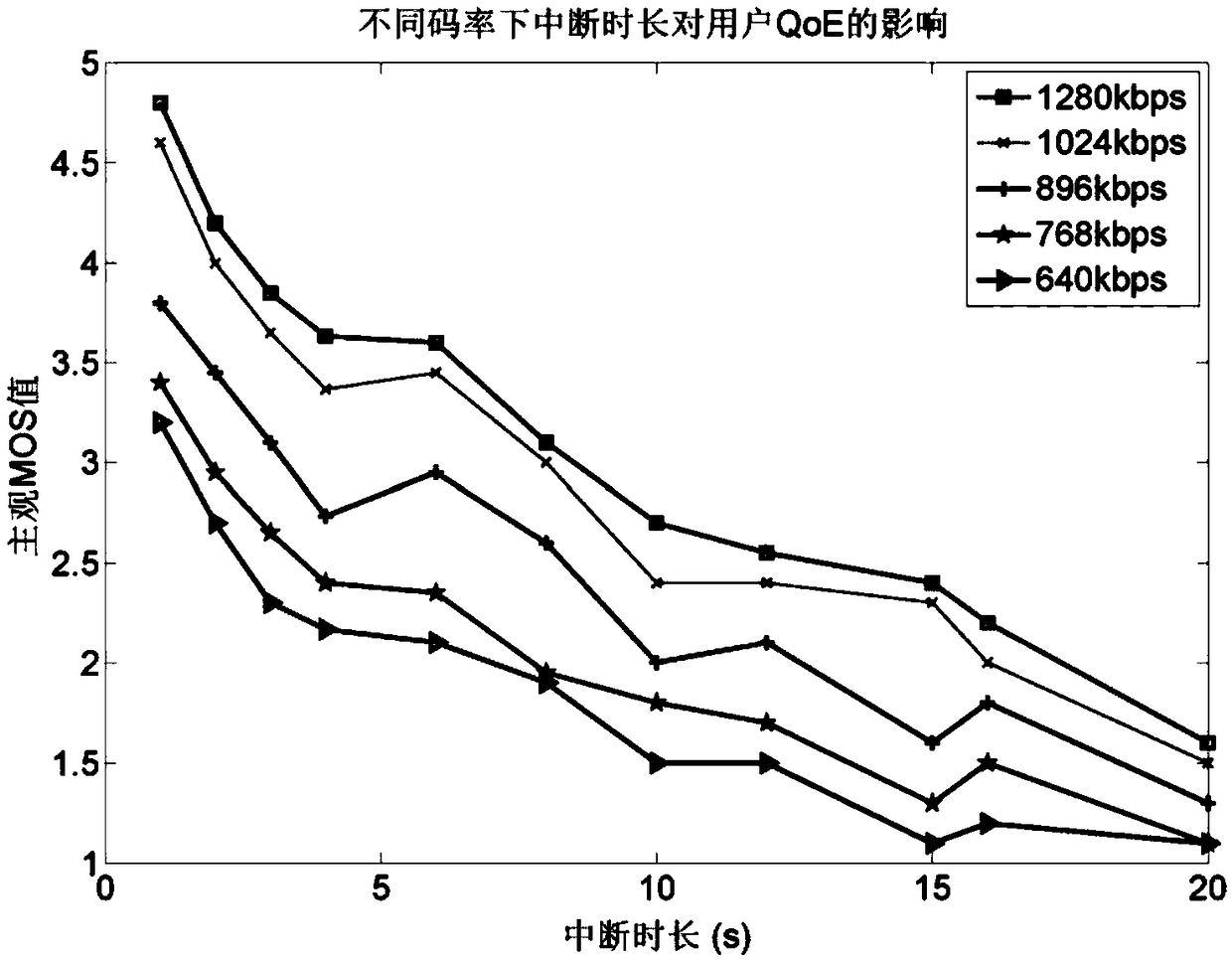

QoE driven video code rate adaptive and resource allocation joint algorithm under LTE network

ActiveCN109327867AMaximize QoEResource maximizationNetwork traffic/resource managementDecision takingSelf adaptive

The invention discloses a QoE driven video bit rate adaptive and resource allocation joint algorithm under an LTE network. A QoE prediction model based on video segment features and playback information is established; and five factors such as video segment bit rates, initial delay, interruption duration, interruption times and quality fluctuations are taken into consideration. According to the prediction model, subjective quality of experience when users watch videos can be accurately predicted. A base station global uniform deciding video request and resource allocation joint algorithm provided by the invention comprises the steps that a base station determines a user set to which network resources need to be allocated according to buffer information fed back by the users; current to-be-allocated RBs are found, and QoE and QoE gain values of the videos of quality versions employed by user requests are computed when the RBs are allocated to all users; and the current RB is allocated to the user with the maximum gain value, until all RBs are allocated completely. According to the algorithm, channel condition of the users is taken into comprehensive consideration, and on the premisethat network resources are limited, the subjective quality of experience of watching the videos by all users in the LTE network is improved.

Owner:XI AN JIAOTONG UNIV

Fluidized-bed gasifier fly ash granules and production method thereof

The invention discloses fluidized-bed gasifier fly ash granules. The fluidized-bed gasifier fly ash granules are prepared by mixing 50-60% of fluidized-bed gasifier charged raw material pulverized coal, 40-50% of fluidized-bed gasified fly ash and 8-10% of binder in percentage by weight together, wherein the binder is formed by mixing 10-20% of cement and 80-90% of sodium silicate in percentage by weight together; the production method of the fluidized-bed gasifier fly ash granules comprises the following steps: (1) blending the fluidized-bed gasifier charged raw material pulverized coal and the fluidized-bed gasified fly ash evenly; (2) adding the binder, adding an appropriate amount of water and stirring to obtain a mixture; (3) performing cold rolling on the mixture into coal granules having a diameter in the range of 5-10mm; (4) naturally air-drying or drying the coal granules before being applied to combustion in a fluidized-bed boiler. The fluidized-bed gasified fly ash which cannot be utilized reasonably in the prior art is pelleted and applied to combustion in the fluidized-bed boiler, and therefore, the coal resources can be utilized sufficiently, the cost of an enterprise is reduced and the maximum resource utilization is realized, and meanwhile, the fly ash-induced pollution on the environment can be reduced and the goals of high energy efficiency, low energy consumption and low emission of the enterprise are realized.

Owner:HENAN POLYTECHNIC UNIV

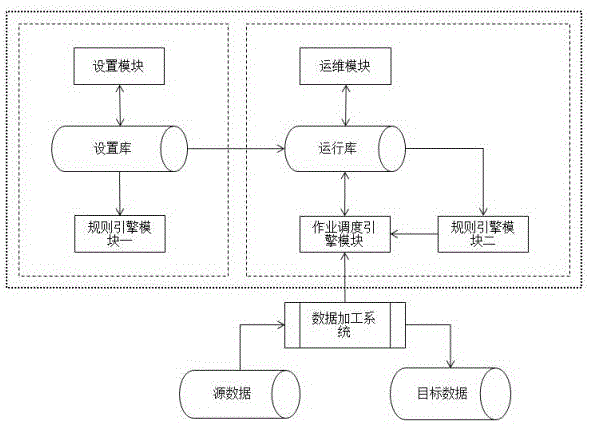

Scheduling system and method for banking data processing operation

InactiveCN106156956AResource maximizationMeet actual needsFinanceResourcesData warehouseStorage garage

The invention discloses a scheduling system and method for banking data processing operation. The scheduling system for the banking data processing operation comprises a setting assembly and an operation maintenance assembly, wherein the setting assembly is used for supporting system definition and maintaining all parameters, and the operation maintenance assembly is used for supporting system operation and maintenance; the setting assembly comprises a setting library, a setting module and a rule engine module I; the operation maintenance assembly comprises an operation maintenance module, an operation library, an operation scheduling engine module and a rule engine module II. According to the system and the method, all data processing operations are loaded to one system based on an operation scheduling rule data model by taking the rule engine module I, the rule engine module II and the operation scheduling engine module as cores, so that the maximized utilization of system resources is achieved, and the automation and visualization of operation scheduling are achieved; the adjustment on size of operation parallelism can be carried out according to quantity of data processed, so that time windows of data processing are reduced; the system and the method can be applied to the data processing operation scheduling of large-sized data marts or data warehouses of banks.

Owner:广东华际友天信息科技有限公司

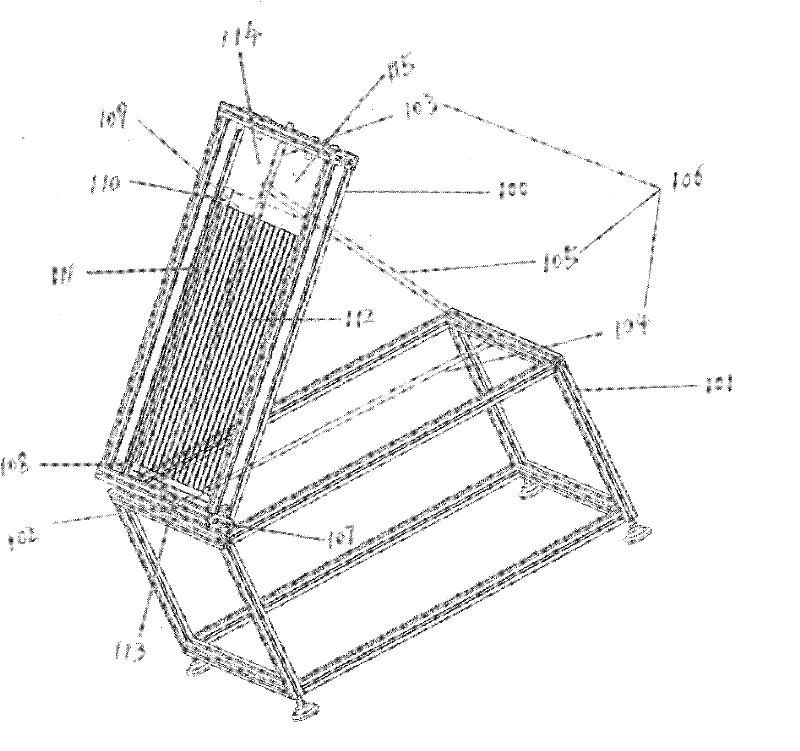

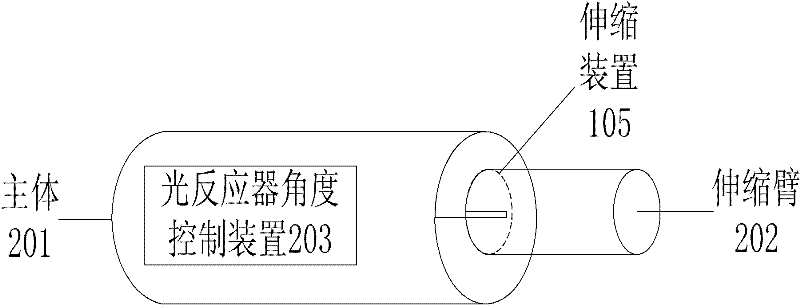

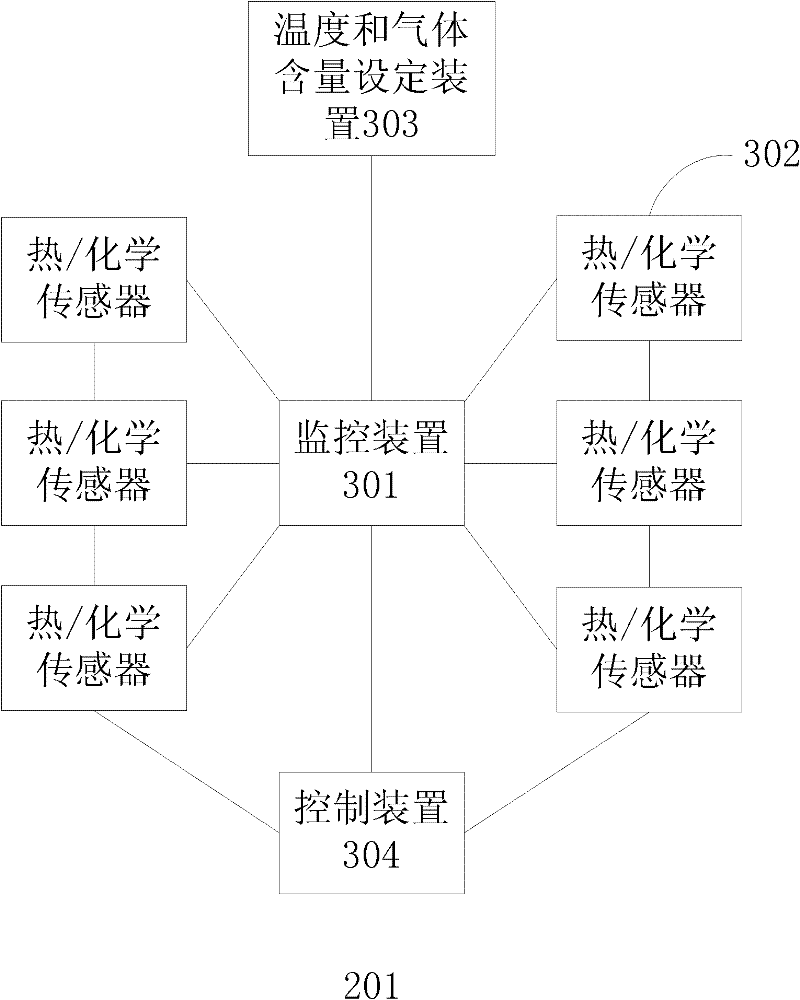

Light utilization regulating device and application thereof to culture of light-energy live beings

InactiveCN102465090AThorough and optimized photosynthesisResource maximizationBioreactor/fermenter combinationsBiological substance pretreatmentsLight energyReaction temperature

The invention discloses a light utilization regulating device, which is connected with a supporting base through a connecting device, wherein a photoreactor body is connected with the supporting base through a mechanical shaft structure, and the photoreactor body is of a cubic closed type structure with a light receiving face. The light utilization regulating device is characterized in that a light-orientation regulating device specifically comprises a photoreactor angle control device, one or a plurality of sensor devices, a temperature and gas content setting device, and a composite expansion and contraction device, wherein the sensor device(s) is / are used for sensing the reaction temperature or the gas content in the photoreactor body and sending information to a monitoring device; and the composite expansion and contraction device is used for regulating an expansion angle between the photoreactor and the supporting base. The invention further discloses application of the light utilization regulating device to culture of light-energy live beings, and the light utilization regulating device disclosed by the invention can be used for realizing culture condition optimization during light-energy live being culture.

Owner:ZHEJIANG QICHENG TECH

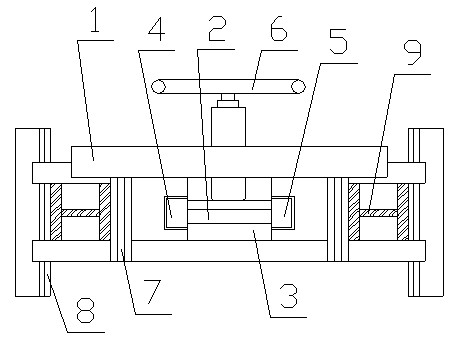

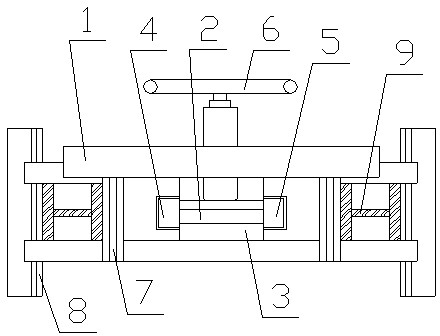

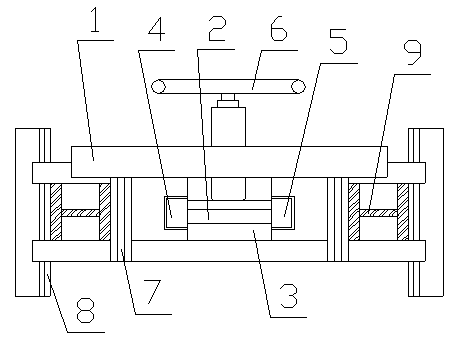

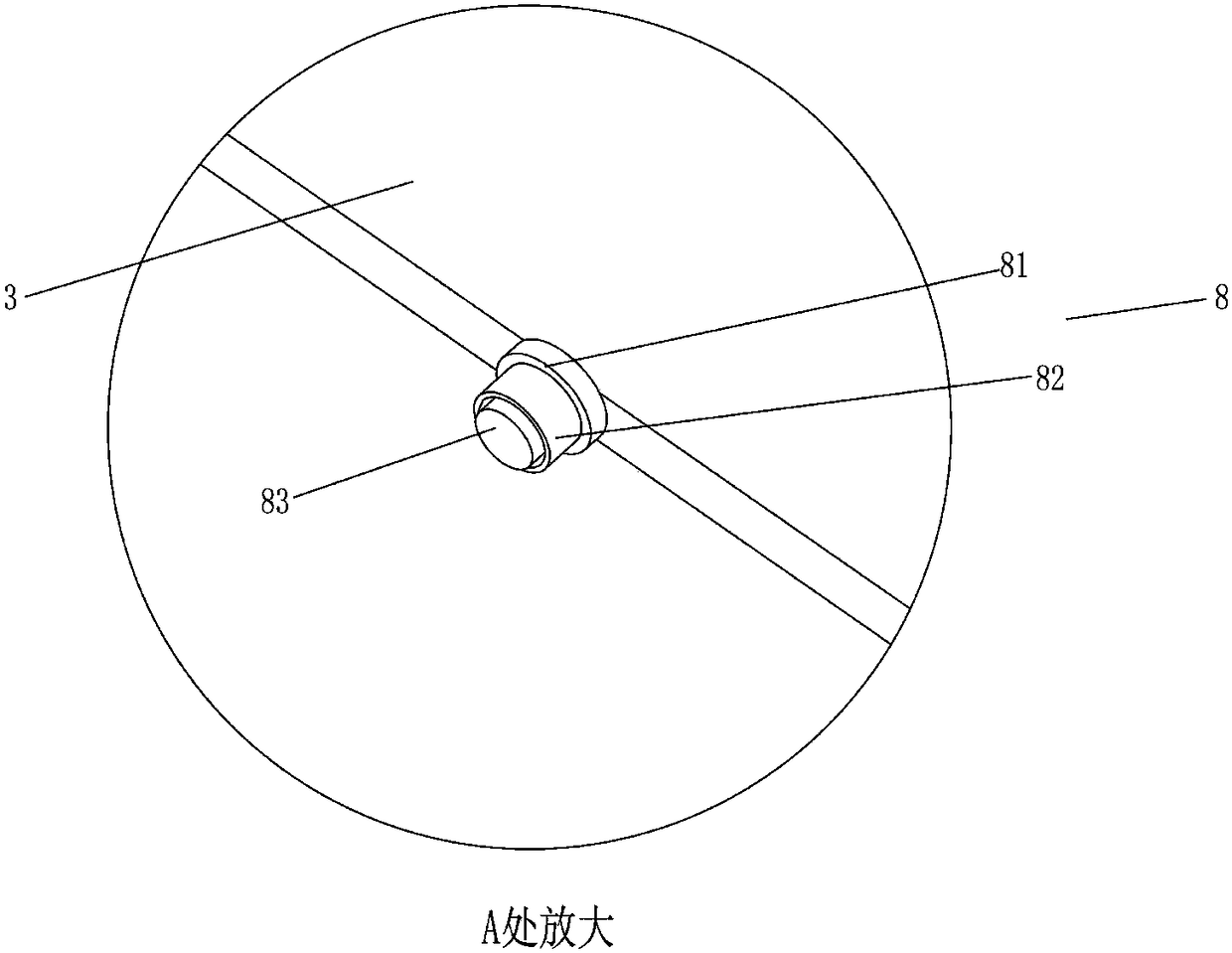

Rolling mill guide mechanism

ActiveCN102513380AAvoid bouncing up and down situationsThe case of bouncing up and down will notGuiding/positioning/aligning arrangementsEngineeringSteel belt

The invention relates to a rolling mill guide mechanism with the advantages that the combined fixation mode is adopted, the material position guide can be realized, the finished product rate of materials can be greatly improved, the waste of strip heads and strip tails of the materials is also reduced, and a large number of raw materials are saved. The rolling mill guide mechanism comprises a machine frame, wherein an upper clamping plate and a lower clamping plate are arranged between an upper cross beam and a lower cross beam of the machine frame, a left guide device and a right guide device are arranged at two sides of the upper clamping and the lower clamping plate, the upper cross beam of the machine is provided with a vertical position guide regulator, in addition, a regulating rod arranged at the bottom of the vertical position guide regulator passes through the upper cross beam to be connected with the upper clamping plate, and parts of the upper clamping plate and the lower clamping plate connected with the left guide device and the right guide device are provided with locking plates. The rolling mill guide mechanism has the advantages that 1, a position guide mechanism is applicable to the position guide of materials with different thicknesses, and in addition, the condition of vertical material jumping caused by the shaking generated during the rolling mill operation is avoided; and 2, the position guide mechanism is adopted, the tail parts of finished steel strips and the head parts of non-rolled materials are ensured to pass through a rolling mill for rolling, and the waste of raw materials is reduced.

Owner:浙江富日进精密金属股份有限公司

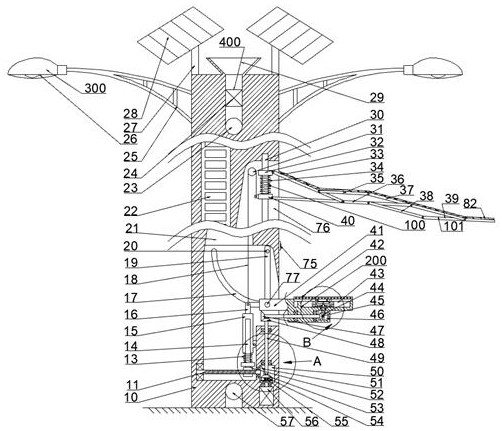

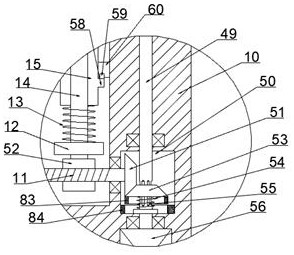

Solar rain-sheltering intelligent street lamp

InactiveCN111928190ASolve the defect of single structure and functionSimple structureMechanical apparatusLighting elementsElectric machineEngineering

The invention discloses a solar rain sheltering intelligent street lamp comprising a lamp pole, an action cavity with a rightward opening is formed in the lamp pole. An umbrella cavity with a rightward opening is formed in the position, located above the action cavity, in the lamp pole in a communicating mode. A fixed pin is fixedly arranged on the rear end wall of the action cavity; a first connecting rod is rotationally arranged on the fixed pin; a seat base perpendicular to the first connecting rod is fixedly arranged at the lower end of the first connecting rod. The solar rain sheltering intelligent street lamp is simple in structure and ingenious in design; the whole use process is powered by solar energy; a storage battery does not need to be charged manually; the use is simple, convenient, green and environment-friendly; a motor is started to enable an umbrella device and a seat device to be automatically opened, pedestrians passing by can hide below the street lamp to sit for rain sheltering, the pedestrians are prevented from being wetted by rain and even catching a cold, humanization is better achieved, resources can be maximized by installing the rain sheltering device on the street lamp, the advantage that the number of street lamps is large is fully utilized, and the defect that an existing street lamp structure is single in function is overcome.

Owner:SHANGHAI KAOMING LIGHTING CO LTD

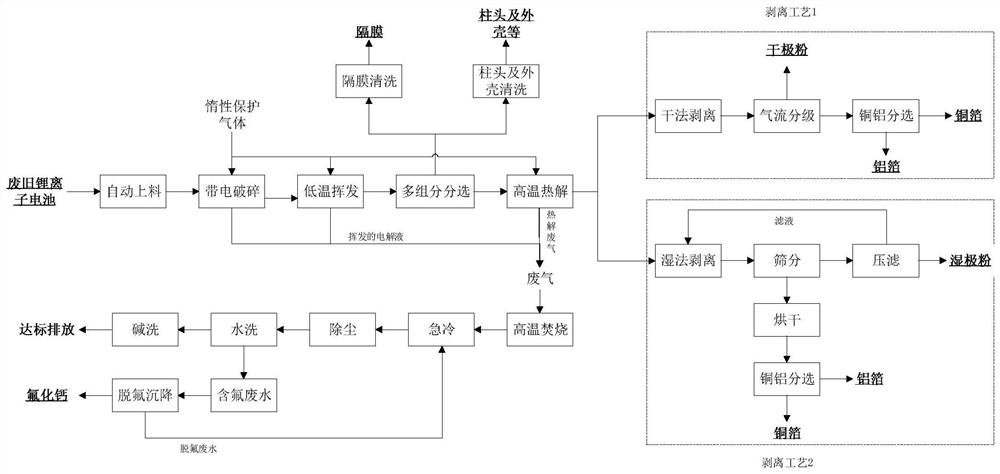

Method for recycling all components of waste lithium battery

InactiveCN114151802AResource maximizationHigh component recoveryWaste accumulators reclaimingIncinerator apparatusProcess engineeringEnvironmental engineering

The invention discloses a method for recycling all components of a waste lithium battery. The method comprises the steps of electrified crushing, low-temperature volatilization, winnowing separation, high-temperature pyrolysis, screening and stripping, color sorting, centralized treatment of tail gas and the like under anaerobic and closed conditions. According to the method, all-component recovery and resource maximization of the waste lithium battery can be realized, the recovery rate of each component is high, the product purity is high, the polar powder recovery rate is 96%-98%, and the grade is 96%-98%; the recovery rate of copper foil and aluminum foil is 95-98%, and the grade is 99%; the recovery rate of shells and column heads is 95-98%, and the grade is 95-98%.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

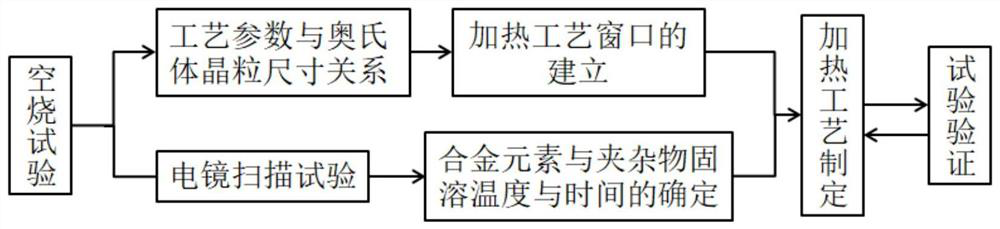

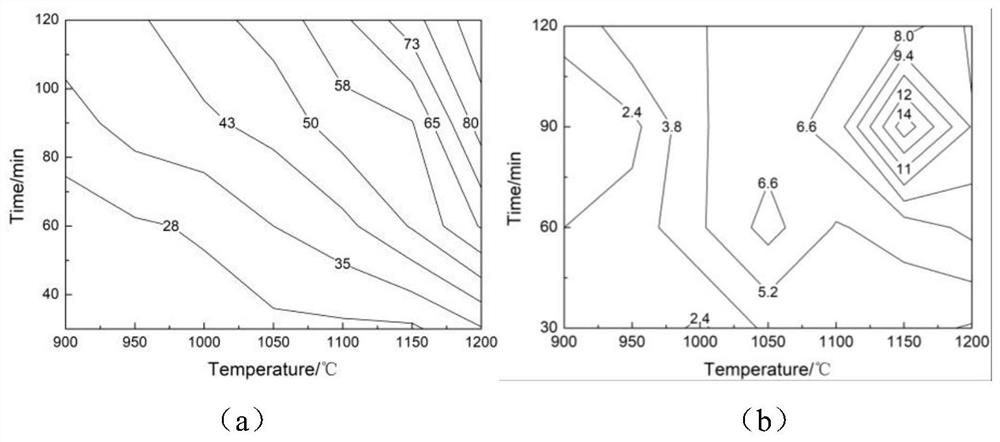

Heating parameter setting method capable of clearly considering structure target requirements

ActiveCN111893267AGet the law of changeAdaptableHeat treatment process controlHeating timeProcess engineering

The invention discloses a heating parameter setting method capable of clearly considering structure target requirements. The heating parameter setting method capable of clearly considering the structure target requirements comprises the following steps that firstly an empty burning sample is obtained by aiming at a target steel grade, the lower limits of heating temperature and heating time are obtained by combining the austenite structure grain sizes of the empty burning sample in austenite structure grain pictures, and the heating temperature and the heating time are further restrained by taking the dissolution condition of inclusions as a standard, so that the reasonable heating time of the target steel grade is obtained; and a reasonable heating process is formulated according to the requirement of a material, the structure change of the material in the heating process is accurately controlled, the reasonability of the heated blank structure is guaranteed, and resource utilizationis maximized. According to the method, the dissolution condition of the inclusions in the material along with the heating temperature and the heat preservation time can be obtained according to the size change of the inclusions at different times, a reasonable heating process can be formulated according to the field condition requirements, and resource utilization is maximized.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

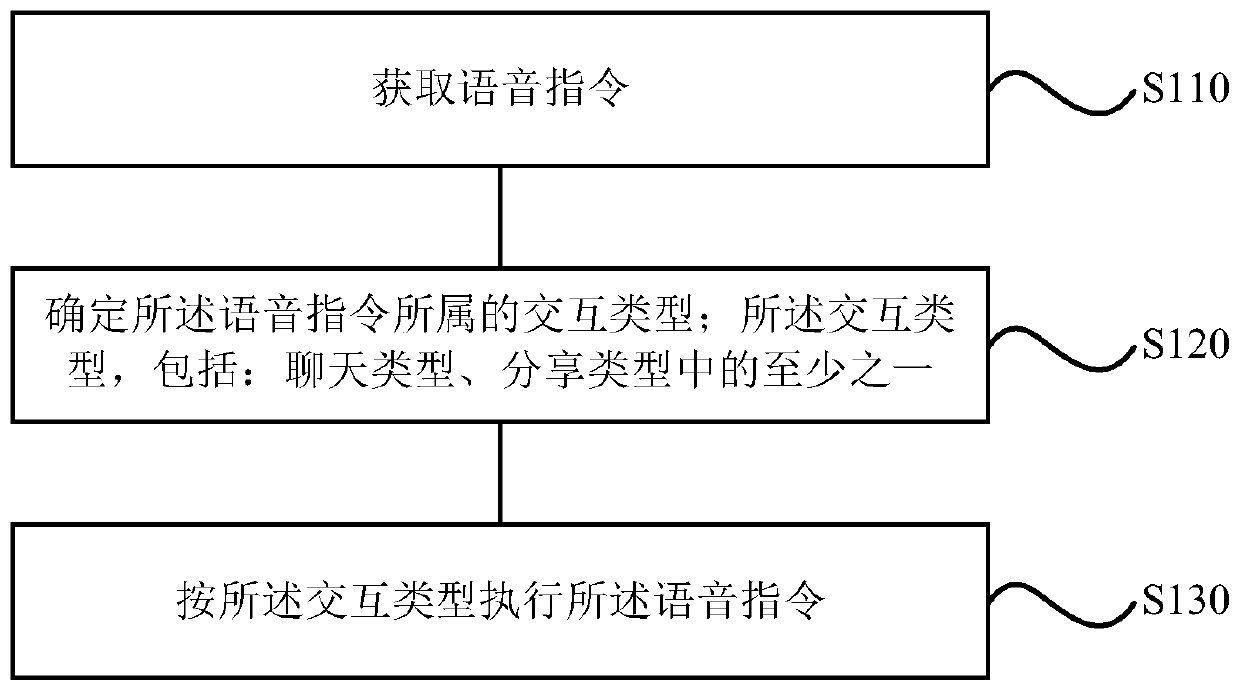

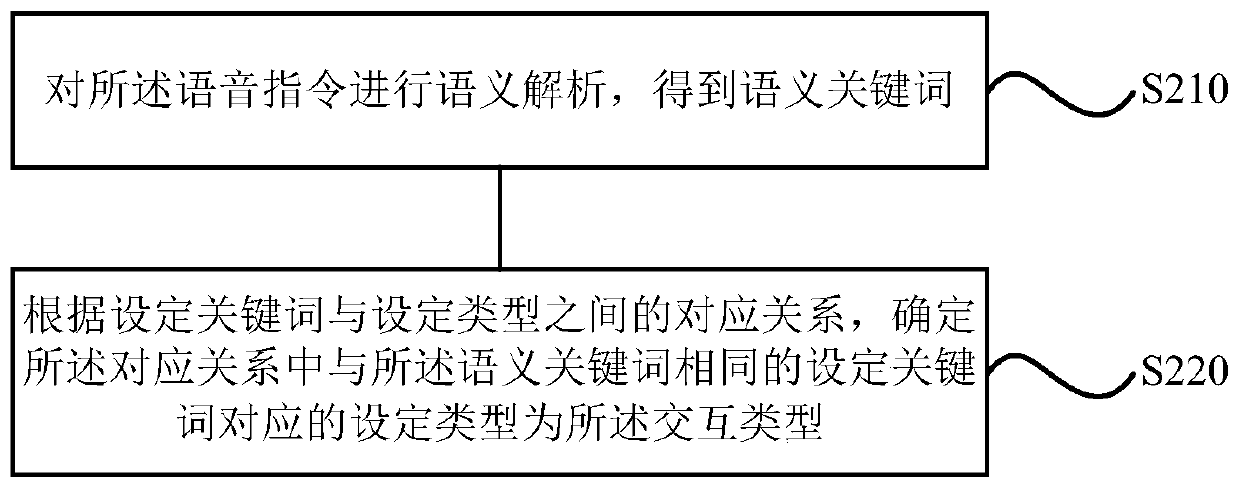

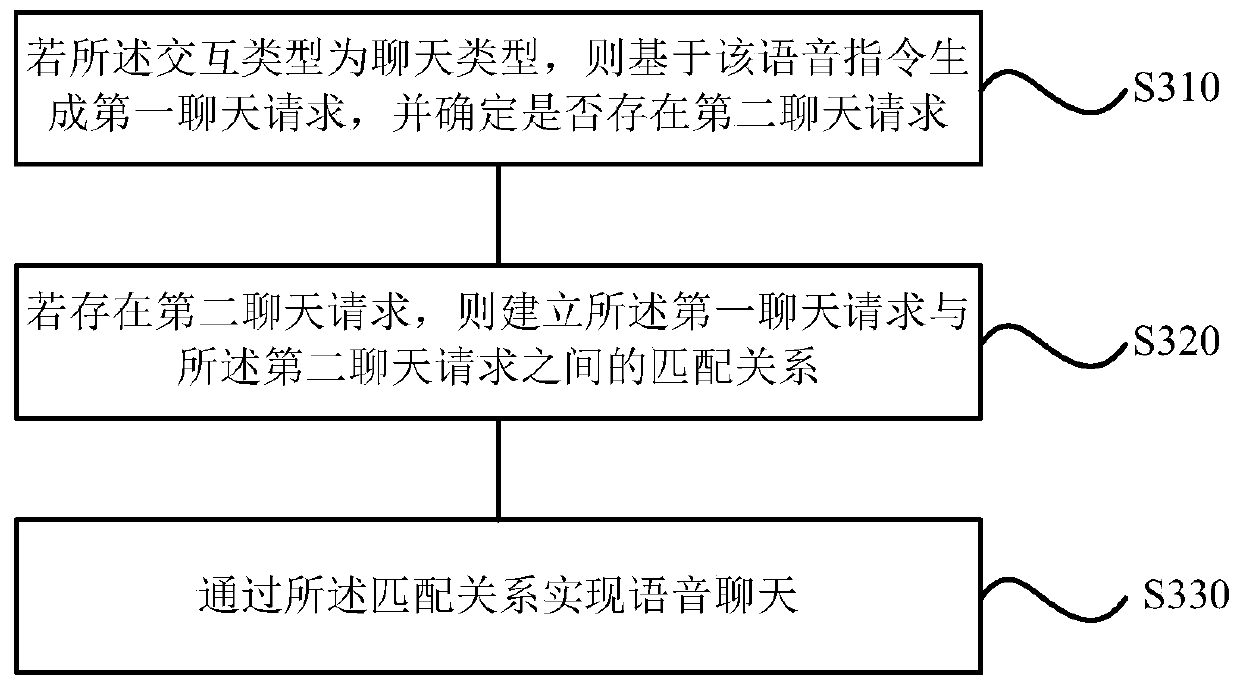

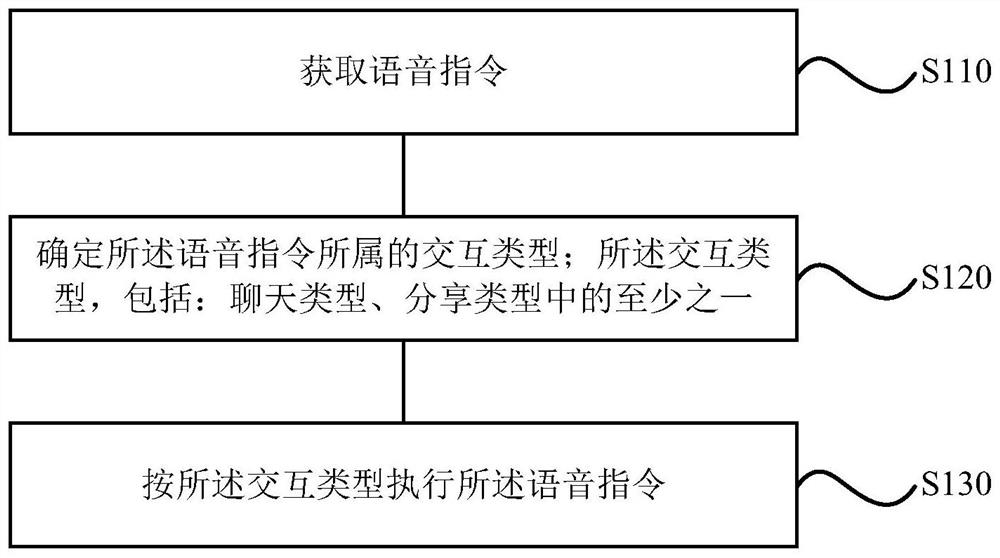

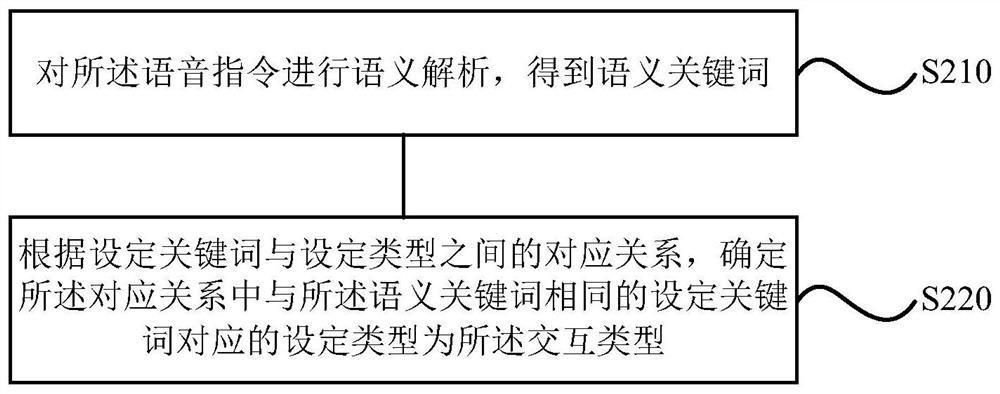

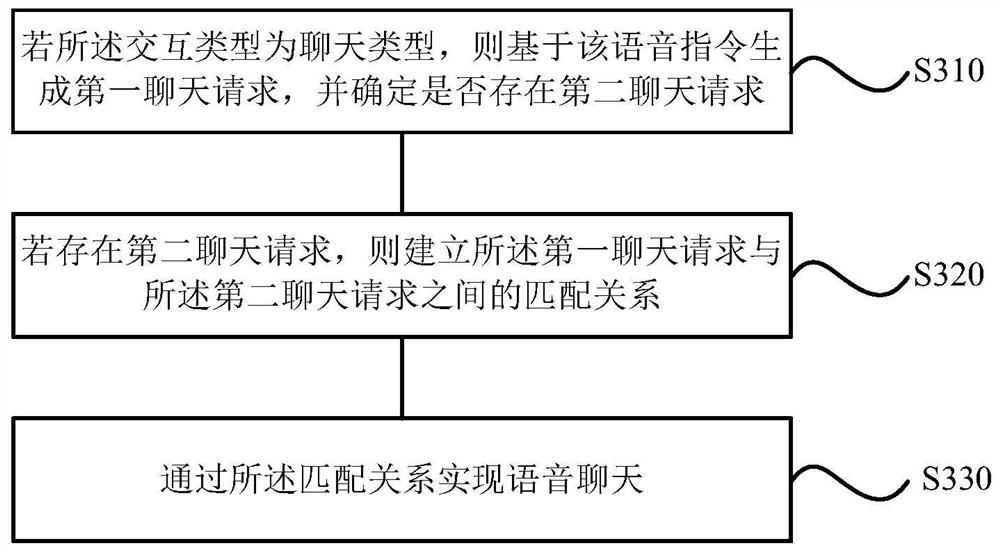

Voice interaction method and device, storage medium and air conditioner

ActiveCN109903755AVersatileImprove experienceMechanical apparatusSpace heating and ventilation safety systemsHuman–computer interactionInteraction type

The invention discloses a voice interaction method and device, a storage medium and an air conditioner. The method includes the steps: acquiring voice commands; determining interaction types of the voice commands; executing the voice commands according to the interaction types, wherein the interaction types include at least one of a chatting type and a sharing type. According to the scheme, the problem of poor user experience caused by fewer interaction functions of intelligent equipment can be solved, and user experience can be improved.

Owner:GREE ELECTRIC APPLIANCES INC

Preparation method of lemna minor protein feed

InactiveCN108041277AMaximize utilizationResource maximizationAnimal feeding stuffAccessory food factorsPhosphatePotassium

The invention discloses a preparation method of a lemna minor protein feed. The preparation method comprises the following steps of (1) taking 80 parts by weight of lemna minor under the condition of45 DEG C, performing drying until the water content is 80%, and performing crushing to obtain a mixture 1; (2) adding 20 parts of corn flour to the mixture 1 in step (1) to obtain a mixture 2; (3) adding 1% of nutritive salt liquid to the mixture 2 in the step (2), wherein the nutritive salt liquid comprises 0.18% of ammonium sulfate, 0.36% of potassium dihydrogen phosphate, 0.27% of magnesium sulphate and 1000ml of water to obtain a mixture 3; (4) placing the mixture 3 in the step (3) under the condition of 121 DEG C for heating for 20min, and performing sterilization to obtain a culture medium; (5) performing inoculating in the mixture in the step C in the proportion of geotrichum candidum to candida utilis to beer microzyme culture medium bacteria being 2.9 to 2.5 to 2.5, and at the temperature of 30 DEG C, performing sealed culturing for 80 hours; and (6) performing permanent-temperature drying the mixture in the step D at 65 DEG C to obtain permanent weight, and performing grinding to obtain powder. According to the preparation method of lemna minor fermentation protein powder, provided by the invention, the economical efficiency can be increased, and the lemna minor sources can be used to the maximum extent.

Owner:CHONGQING SHENGSHUN TECH

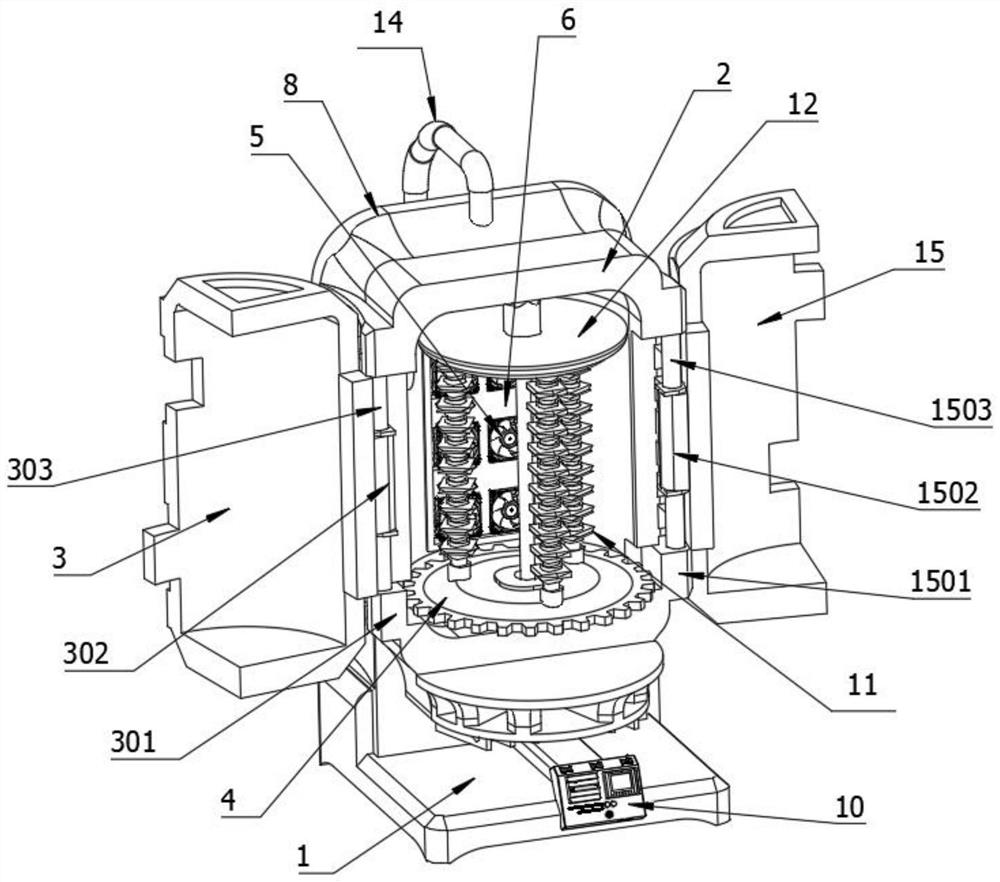

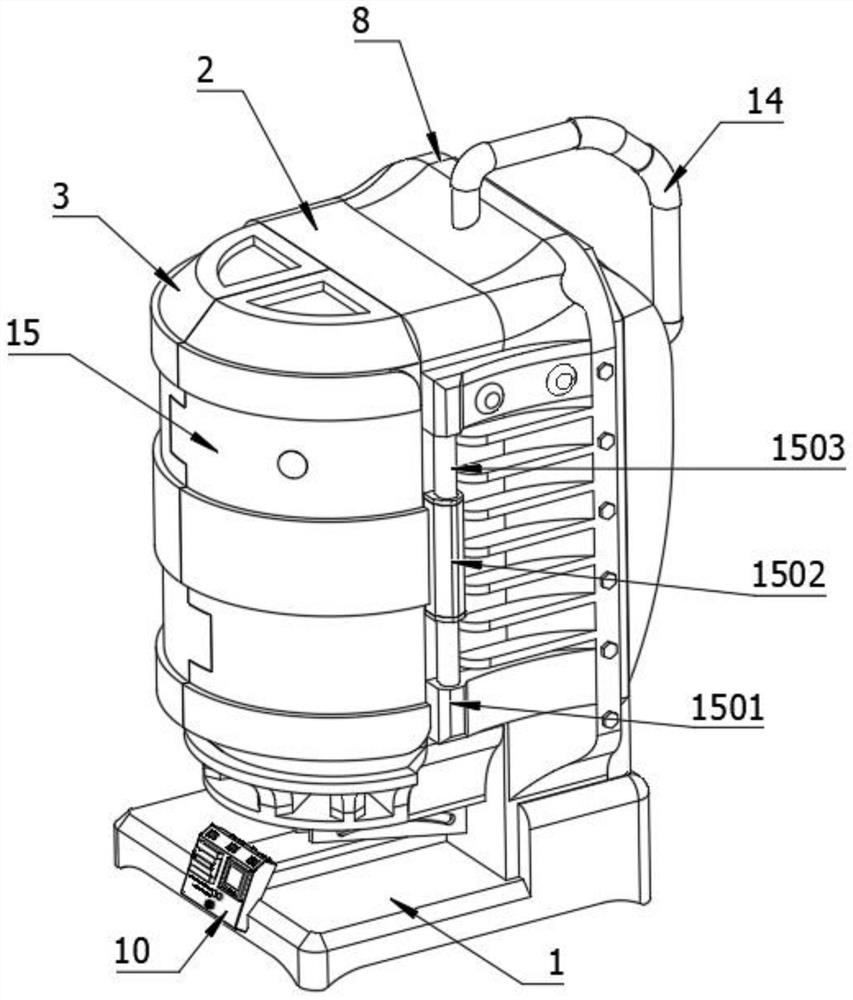

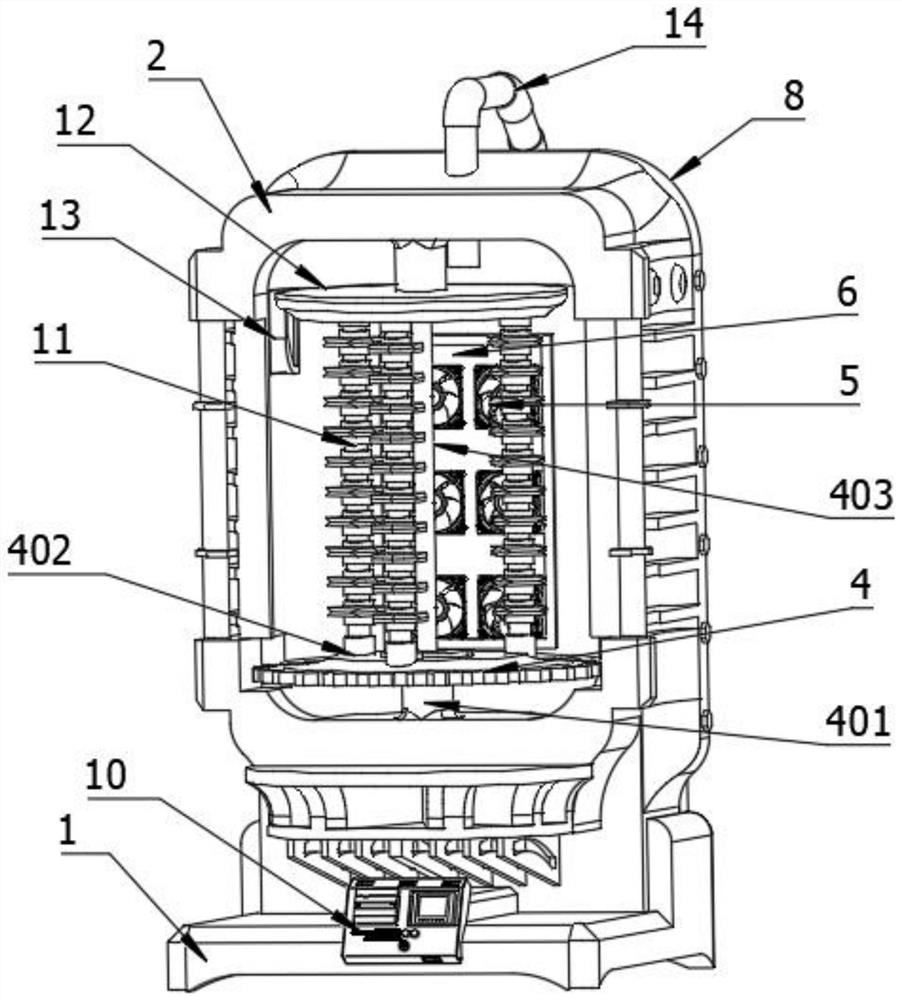

High-pressure ion bombardment vacuum coating device and coating method thereof

PendingCN112126901ARealize automatic controlSave resourcesVacuum evaporation coatingSputtering coatingIon bombardmentAutomatic control

The invention discloses a high-pressure ion bombardment vacuum coating device and a coating method thereof. The high-pressure ion bombardment vacuum coating device comprises a base, a main shell is fixedly connected to the upper surface of the base, a first connecting rod and a second connecting rod are welded to the outer surface of a first connecting shaft and the outer surface of a second connecting shaft respectively, a right rotating shell is welded to the outer surface of the first connecting rod, a left rotating shell is welded to the outer surface of the second connecting rod, a thirdmotor is welded to the inner side wall of the main shell, and an output shaft of the third motor is fixedly connected with a rotating base. All electrical components are conducted through programmingof a programmable logic controller, so that automatic control is realized. Chemical hot gas generated from coating material is decomposed into non-condensable gas and water which are harmless to humanhealth through fraction of an evaporator, then the non-condensable gas and the water are discharged, the water can be recycled after being refined from the outside, and the non-condensable gas is guided into the device through a gas guide pipe to provide heat and pressure as a useful waste.

Owner:张益明

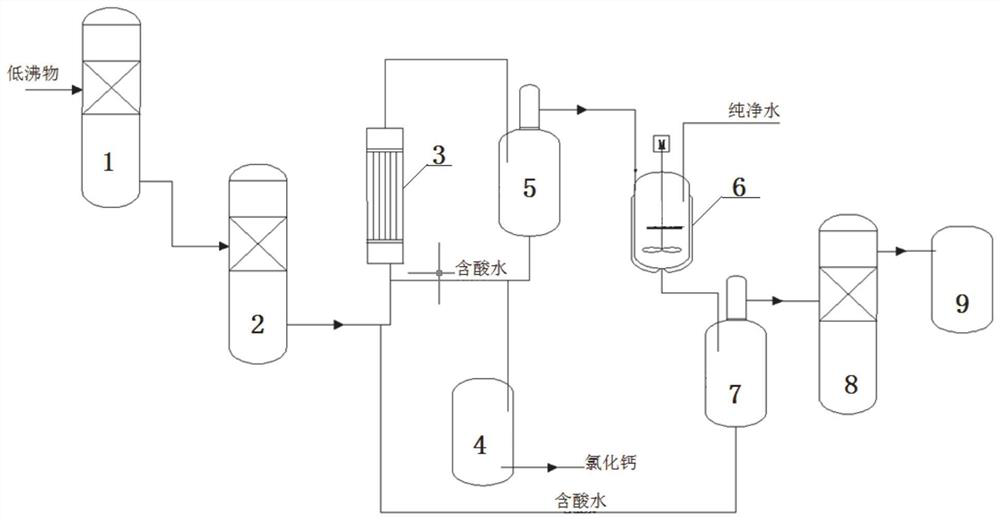

Method and system for preparing tetramethyldihydrodisiloxane by hydrolyzing organic silicon low-boiling-point substance and comprehensive utilization method

ActiveCN111909191AReduce processing costsImprove utilization efficiencySilicon organic compoundsChemical industryDisiloxaneMeth-

The invention discloses a method and a system for preparing tetramethyldihydrodisiloxane by hydrolyzing an organosilicon low-boiling-point substance and a comprehensive utilization method, and belongsto the field of organosilicon production. The method comprises the following steps: separating and purifying dimethyl monochlorosilane from a low-boiling-point substance, hydrolyzing the dimethyl monochlorosilane with higher content in a loop by using a hydrolysis process, and fully mixing reactants in the hydrolysis loop through a static mixer; wherein the temperature of process water is controlled to be about 10 DEG C through a cooler, and the hydrolysis temperature is controlled to be about 10 DEG C through a circulating cooler; then feeding the reaction mixture to a first layering devicethrough the top of a loop to achieve effective oil-water separation, and feeding hydrolysate (double seal heads) obtained through separation into a hydrolysate intermediate tank to be further settledand dewatered; and performing multi-stage washing and rectification on the crude hydrogen-containing double-end socket to obtain a qualified high-purity hydrogen-containing double-end socket product and 20% hydrochloric acid as a byproduct.

Owner:LUXI CHEM GRP

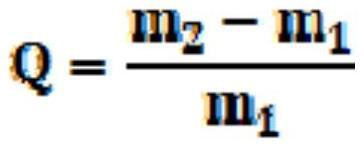

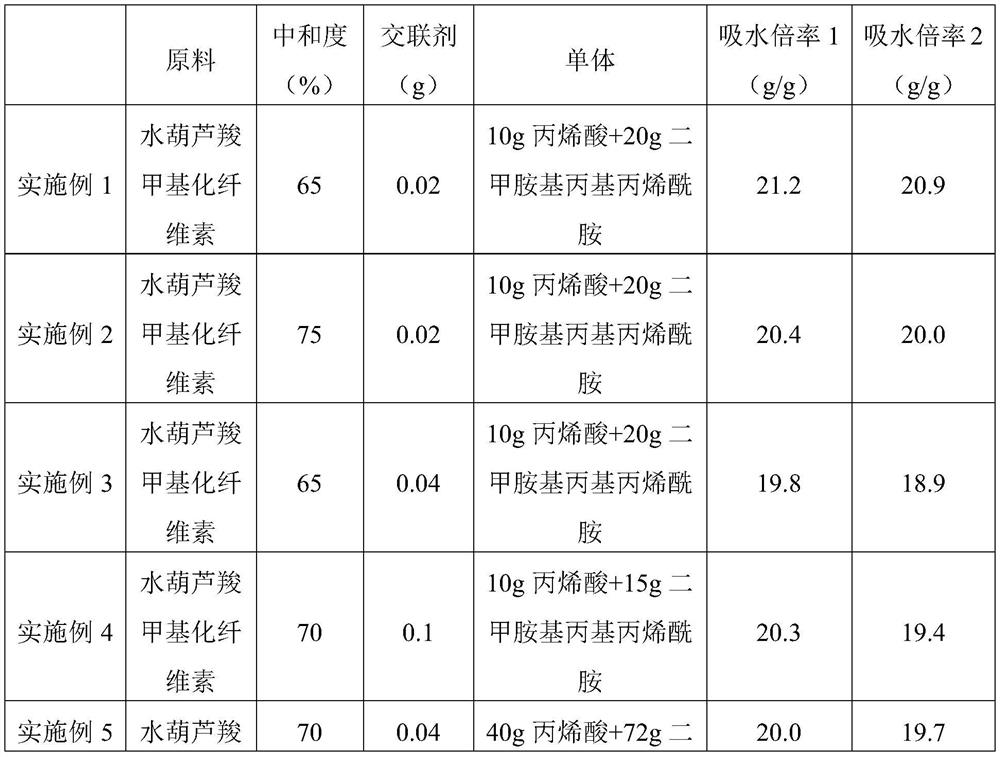

Water hyacinth carboxymethyl cellulose salt-resistant and super absorbent resin and preparation method thereof

The invention discloses a water hyacinth carboxymethyl cellulose salt-resistant and super absorbent resin and a preparation method thereof. The preparation method comprises the following steps: firstly, respectively preparing a mixed monomer solution and a water hyacinth carboxymethyl cellulose solution; introducing nitrogen into the prepared water hyacinth carboxymethyl cellulose solution, adding an initiator and a cross-linking agent to react, adding a mixed monomer solution, stirring, sealing and standing to obtain a resin sample; and finally, shearing and soaking the resin sample, drying, crushing and sieving to obtain the water hyacinth carboxymethyl cellulose salt-resistant and super absorbent resin. According to the prepared high-molecular water-absorbent resin, the degradation performance of the resin is improved, meanwhile, the harm problem caused by water hyacinth is solved, hydrolysis fermentation can be conducted after the resin is abandoned, liquid obtained after degradation can serve as fertilizer and solid to be further treated, and pollution minimization and resource maximization in the whole process can be achieved through application of the resin.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

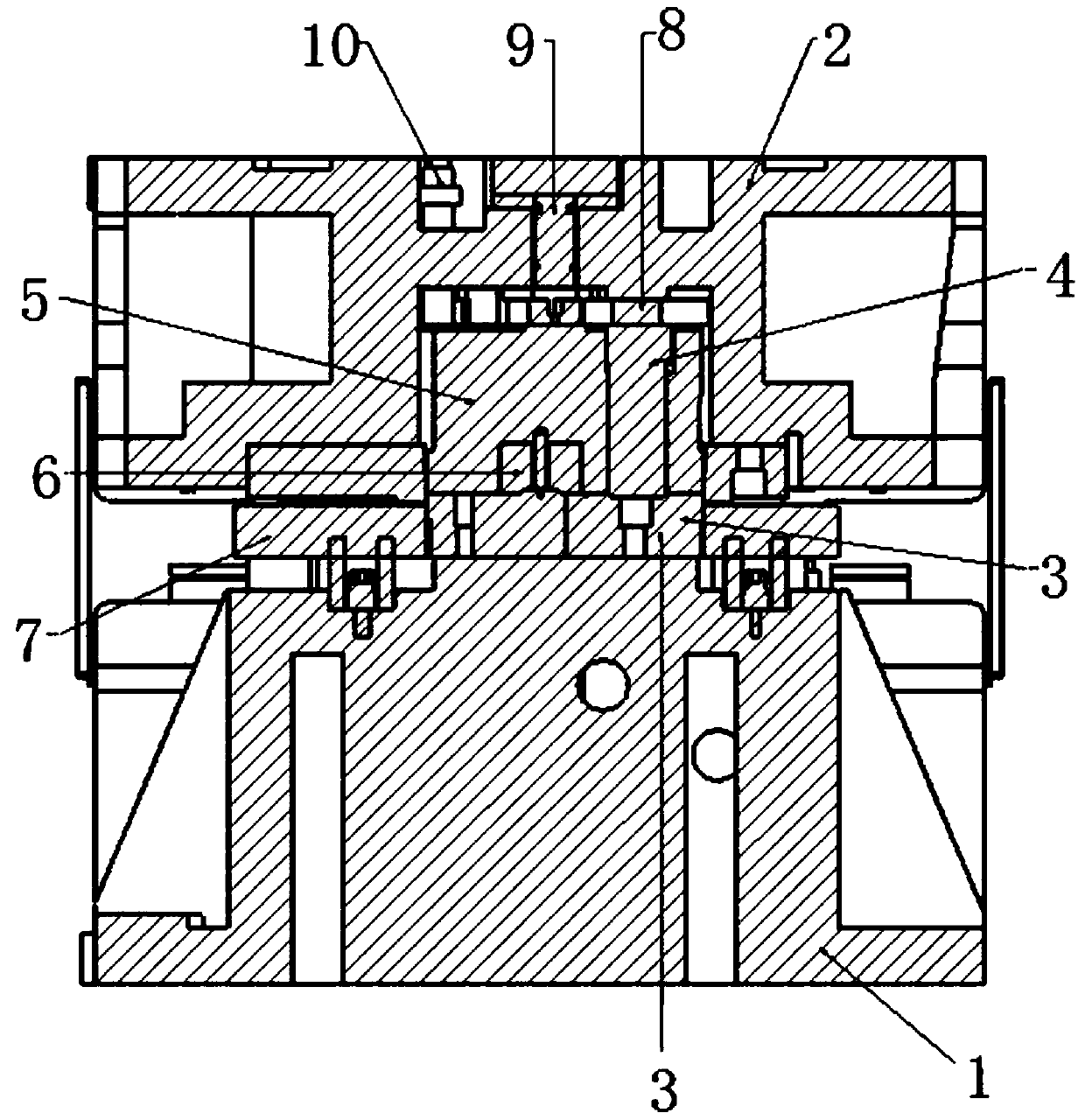

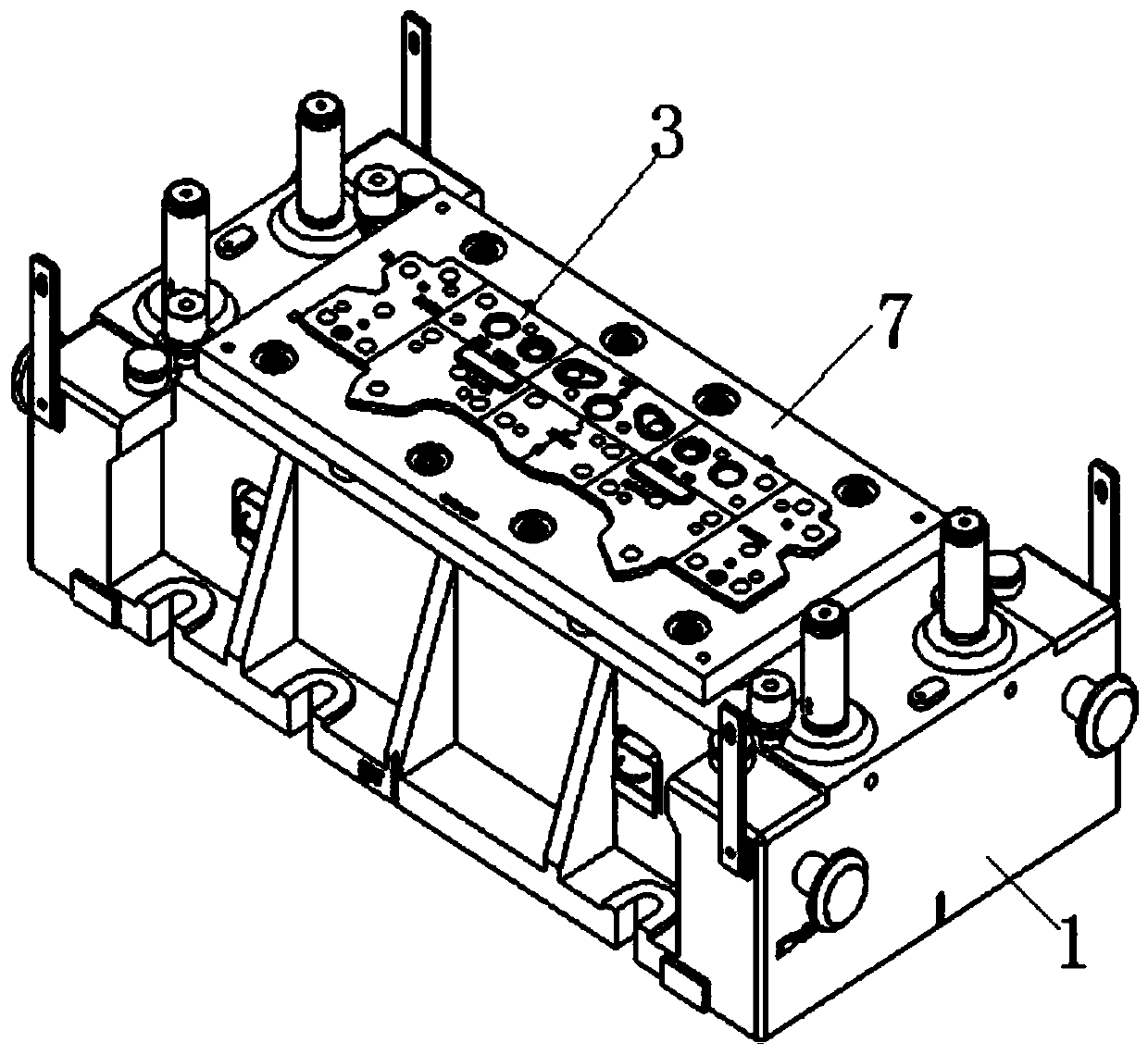

Stiffening beam-rear transverse beam trimming punching and forming combination structure

InactiveCN110405070AReduce production quantityPromote technological developmentShaping toolsLoad-supporting pillarsPunchingNitrogen

The invention provides a stiffening beam-rear transverse beam trimming punching and forming combination structure. The structure comprises a lower mold plate, nitrogen springs and limiting screws. Thelower mold plate and an upper mold plate are buckled together. A material return plate is fixedly installed on the plane of the top of the lower mold plate. According to the stiffening beam-rear transverse beam trimming punching and forming combination structure, a mold structure with the diversified working procedure content is adopted, the outline appearance of the portion of the lower mold plate can be directly fed, trimmed and accomplished by the structure, the material return plate can directly push out blank waste materials, workers conveniently take the blank waste materials, the division of plate materials and product feeding parts is accomplished, and small holes formed in the bottom surface can be punched after trimming is accomplished. In the drawing 2, a small flanging male mold is processed to be a movable part, and the new technological development of the punching mold industry is also promoted. By means of the working procedure, the hole position deformation which is caused by material movement in the punching and forming process is avoided, and the requirement for the precision punching of the hole position in the follow-up process is met. In the current social form, the stiffening beam-rear transverse beam trimming punching and forming combination structure can completely maximize all resources.

Owner:SHIYAN TIANCE MOLD

Rolling mill guide mechanism

ActiveCN102513380BAvoid bouncing up and down situationsThe case of bouncing up and down will notGuiding/positioning/aligning arrangementsEngineeringSteel belt

The invention relates to a rolling mill guide mechanism with the advantages that the combined fixation mode is adopted, the material position guide can be realized, the finished product rate of materials can be greatly improved, the waste of strip heads and strip tails of the materials is also reduced, and a large number of raw materials are saved. The rolling mill guide mechanism comprises a machine frame, wherein an upper clamping plate and a lower clamping plate are arranged between an upper cross beam and a lower cross beam of the machine frame, a left guide device and a right guide device are arranged at two sides of the upper clamping and the lower clamping plate, the upper cross beam of the machine is provided with a vertical position guide regulator, in addition, a regulating rod arranged at the bottom of the vertical position guide regulator passes through the upper cross beam to be connected with the upper clamping plate, and parts of the upper clamping plate and the lower clamping plate connected with the left guide device and the right guide device are provided with locking plates. The rolling mill guide mechanism has the advantages that 1, a position guide mechanism is applicable to the position guide of materials with different thicknesses, and in addition, the condition of vertical material jumping caused by the shaking generated during the rolling mill operation is avoided; and 2, the position guide mechanism is adopted, the tail parts of finished steel strips and the head parts of non-rolled materials are ensured to pass through a rolling mill for rolling, and the waste of raw materials is reduced.

Owner:浙江富日进精密金属股份有限公司

Silver fiber antibacterial radiation-proof constant-temperature fabric and preparation method thereof

InactiveCN111055553AHas antimicrobial propertiesMaximize the use of resourcesCarbon fibresBiochemical fibre treatmentFiberCarbon fibers

The invention provides a silver fiber antibacterial radiation-proof constant-temperature fabric, which belongs to the technical field of textiles. The silver fiber antibacterial radiation-proof constant-temperature fabric is composed of a base layer, a sponge layer, a center layer, a sponge layer and a base layer from inside to outside, the base layer is made of radiation-proof antibacterial silver fiber cloth, the sponge layer is made of sponge with the thickness being 3-5 mm, and the center layer is made of core cotton with the thickness being 9-11 mm. The radiation-proof antibacterial silver fiber cloth is prepared by blending cellulose acetate-based carbon fibers and conventional fibers and then adding silver nitrate and a reducing agent. According to the fabric provided by the invention, the waste cotton fabric is used as a raw material, resources are utilized to the maximum extent, and the cost is saved. The fabric provided by the invention has the effects of radiation protection, heat preservation and antibiosis.

Owner:珠海鑫康源新材料科技有限公司 +1

A three-dimensional electrical impedance imaging system and imaging method of respiratory process based on pxi bus

InactiveCN103690166BAvoid time costReduce maintenance costsDiagnostic recording/measuringSensorsFiltrationSignal on

Owner:TIANJIN UNIV OF SCI & TECH

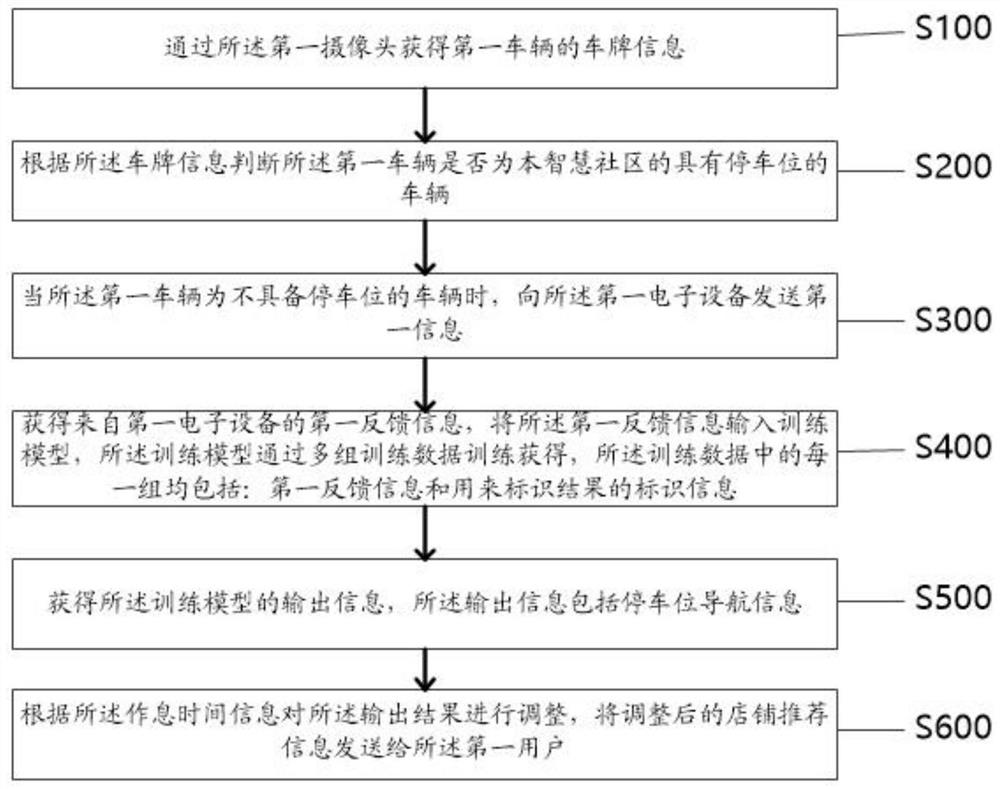

Parking method and system for smart community

InactiveCN112185164AOptimize parking management systemResource maximizationIndication of parksing free spacesNeural learning methodsParking spaceCommunity setting

The invention discloses a smart community parking method and system, and the method is applied to a smart community parking system. The smart community parking system is in communication connection with a first electronic device and is configured with a first camera, and the method comprises the following steps: acquiring license plate information of a first vehicle through the first camera; judging whether the first vehicle is a vehicle with a parking space in the smart community or not according to the license plate information; when the first vehicle is a vehicle without a parking space, sending first information to the first electronic device; acquiring first feedback information from the first electronic device, and inputting the first feedback information into a training model, wherein the output information includes parking space navigation information; and sending the navigation information to the first electronic device. The technical problems that in the prior art, parking space resources are wasted, parking space spare time cannot be reasonably utilized, the time spent on parking is long, and high-quality parking service cannot be obtained are solved.

Owner:苏州立楚信息技术有限公司

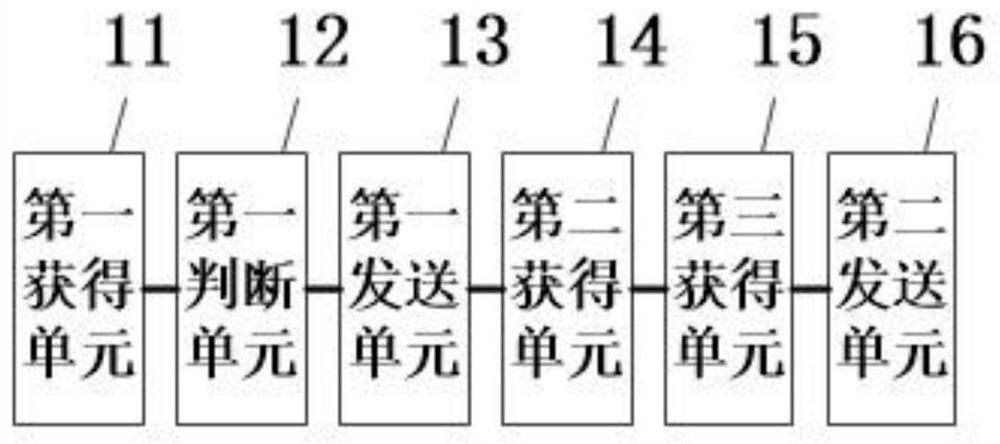

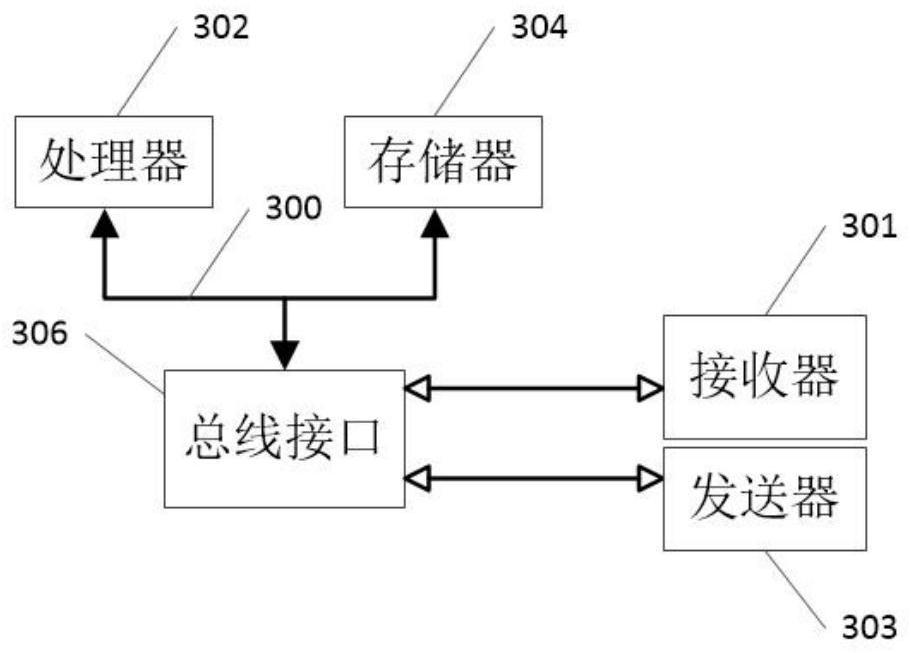

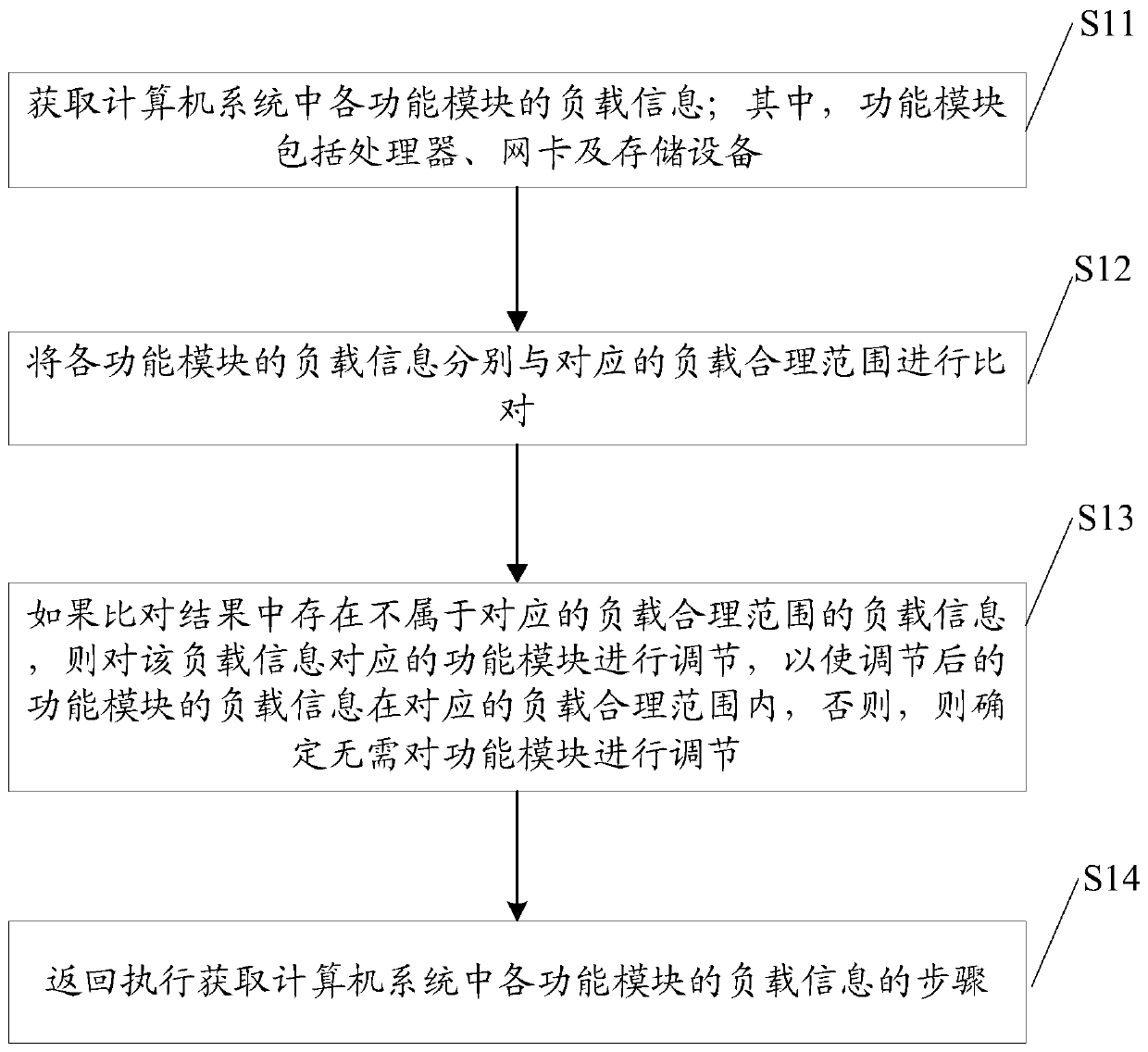

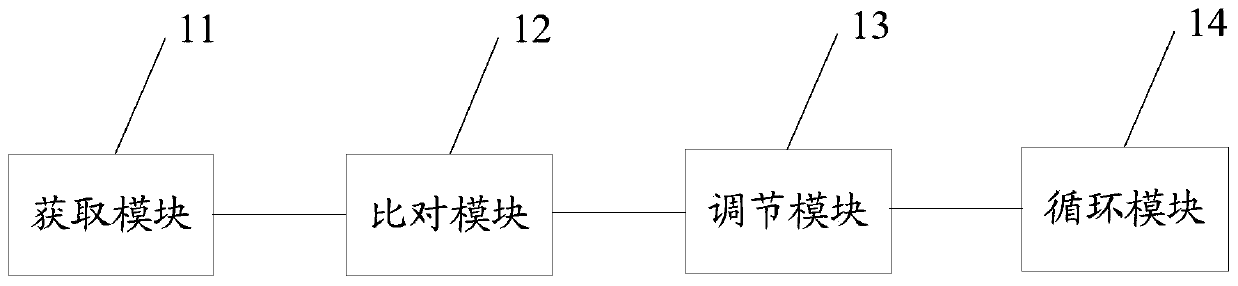

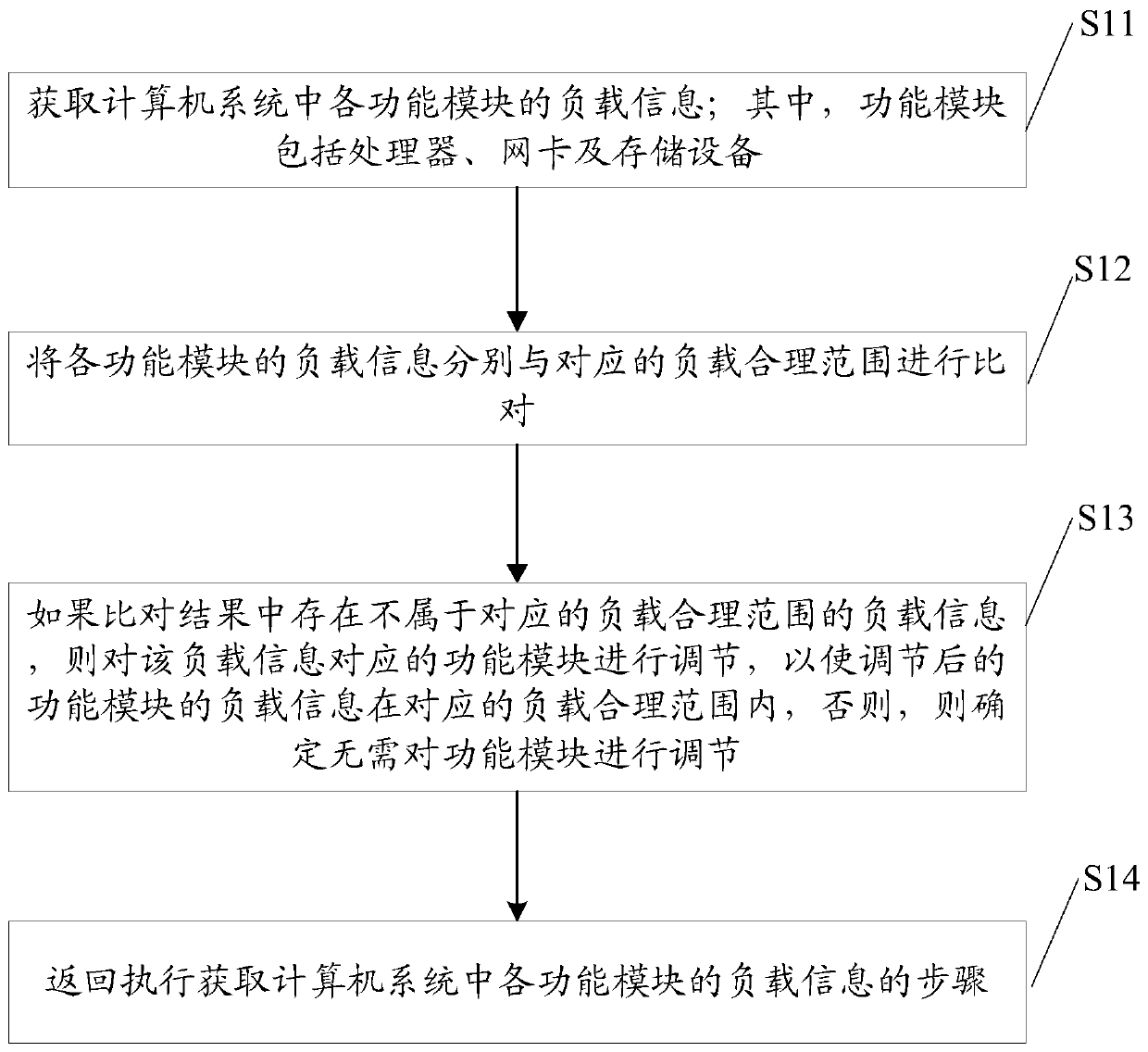

Dynamic adjustment method, device and equipment of functional modules and storage medium

InactiveCN111124677AAvoid wastingMeet resource requirementsResource allocationControl engineeringComputer science

The invention discloses a dynamic adjustment method, device and equipment for functional modules and a storage medium. The method comprises the following steps: acquiring load information of each functional module in a computer system; wherein the function module comprises a processor, a network adapter and a storage device; comparing the load information of each function module with the corresponding reasonable load range; if the load information which does not belong to the corresponding reasonable load range exists in the comparison result, adjusting the function module corresponding to theload information so that the load information of the adjusted function module can be within the corresponding reasonable load range, and otherwise, determining that the function module does not needto be adjusted; and returning to execute the step of acquiring the load information of each functional module in the computer system. According to the invention, resource waste caused by load reduction can be avoided, and meanwhile, the situation that the functional modules in the computer system cannot meet the resource requirements of the load condition can be avoided, so that the resources of the computer system are maximized.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Fluidized bed gasifier fly ash granule and its processing method

The invention discloses fluidized-bed gasifier fly ash granules. The fluidized-bed gasifier fly ash granules are prepared by mixing 50-60% of fluidized-bed gasifier charged raw material pulverized coal, 40-50% of fluidized-bed gasified fly ash and 8-10% of binder in percentage by weight together, wherein the binder is formed by mixing 10-20% of cement and 80-90% of sodium silicate in percentage by weight together; the production method of the fluidized-bed gasifier fly ash granules comprises the following steps: (1) blending the fluidized-bed gasifier charged raw material pulverized coal and the fluidized-bed gasified fly ash evenly; (2) adding the binder, adding an appropriate amount of water and stirring to obtain a mixture; (3) performing cold rolling on the mixture into coal granules having a diameter in the range of 5-10mm; (4) naturally air-drying or drying the coal granules before being applied to combustion in a fluidized-bed boiler. The fluidized-bed gasified fly ash which cannot be utilized reasonably in the prior art is pelleted and applied to combustion in the fluidized-bed boiler, and therefore, the coal resources can be utilized sufficiently, the cost of an enterprise is reduced and the maximum resource utilization is realized, and meanwhile, the fly ash-induced pollution on the environment can be reduced and the goals of high energy efficiency, low energy consumption and low emission of the enterprise are realized.

Owner:HENAN POLYTECHNIC UNIV

Ginseng and black garlic essence liquid and preparation method thereof

The present invention discloses ginseng and black garlic essence liquid and a preparation method thereof. The ginseng and black garlic essence liquid is prepared from diced black garlic, fresh ginsengslices and pure water as raw materials, and prepared by high-pressure cooking, reduced-pressure cooking, filtration, soaking, vacuum concentration, microwave sterilization, etc. The mass ratio of thediced black garlic, fresh ginseng slices and pure water is 1:(0.4-0.6):(5-7). The total sugar content of the ginseng and black garlic essence liquid is 15-35%. The ginseng and black garlic essence liquid expands flavor of black garlic essence liquid, is not easy to absorb, also has functions of improving human body immunity, preventing aging, etc., and meets needs of middle-aged and old people. The preparation method enables the ginseng and black garlic essence liquid to maintain aroma of the black garlic and nutrients in the ginseng and black garlic.

Owner:江苏维昌生物科技有限公司

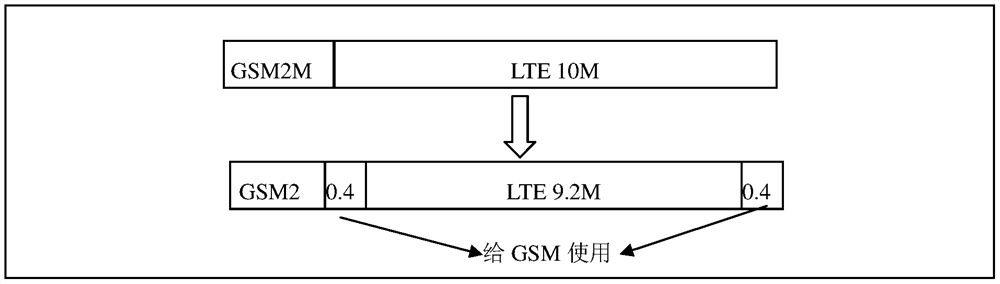

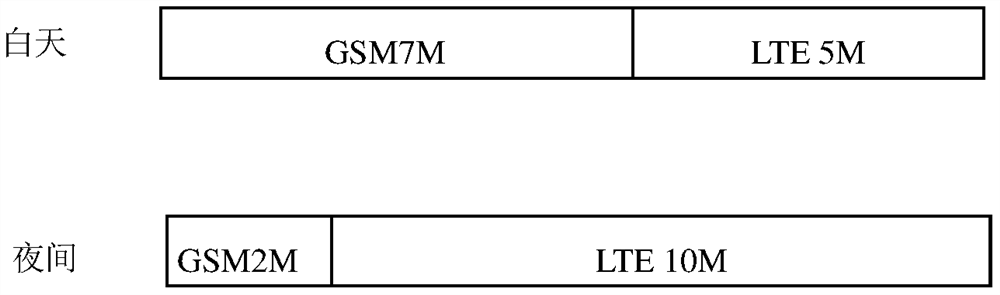

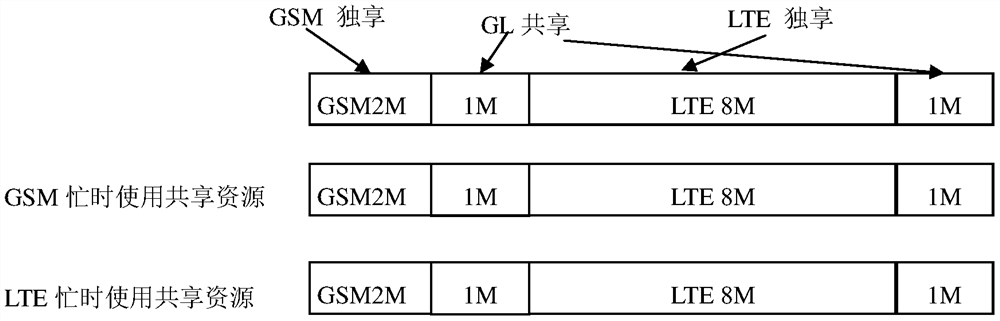

Spectrum resource allocation method and device for complete spectrum sharing

ActiveCN109983825BImprove anti-interference abilityReduce distractionsAssess restrictionConnection managementQuality of serviceResource assignment

The present invention relates to a spectrum resource allocation method and device for complete spectrum sharing, the method comprising: a base station acquires a network access request message sent by the terminal in real time, and the network access request message includes at least one of the following: The network standard supported by the terminal, the access service of the terminal, and the service quality QoS of the access service; the base station dynamically allocates spectrum resources to different network standards according to the network access request message; the The base station sends a first network standard access indication message to the terminal, so that the terminal accesses a service through a corresponding network standard according to the first network standard access indication message.

Owner:HUAWEI TECH CO LTD

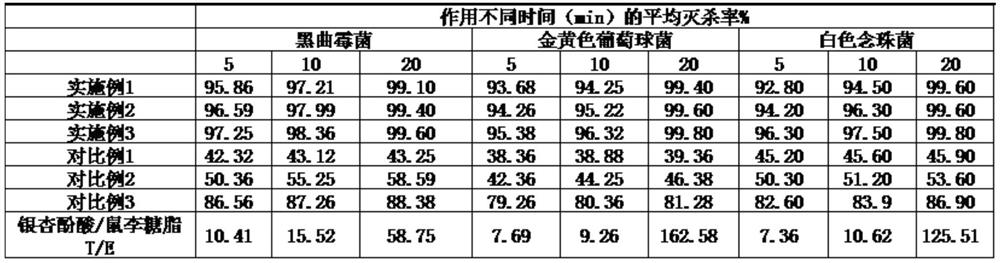

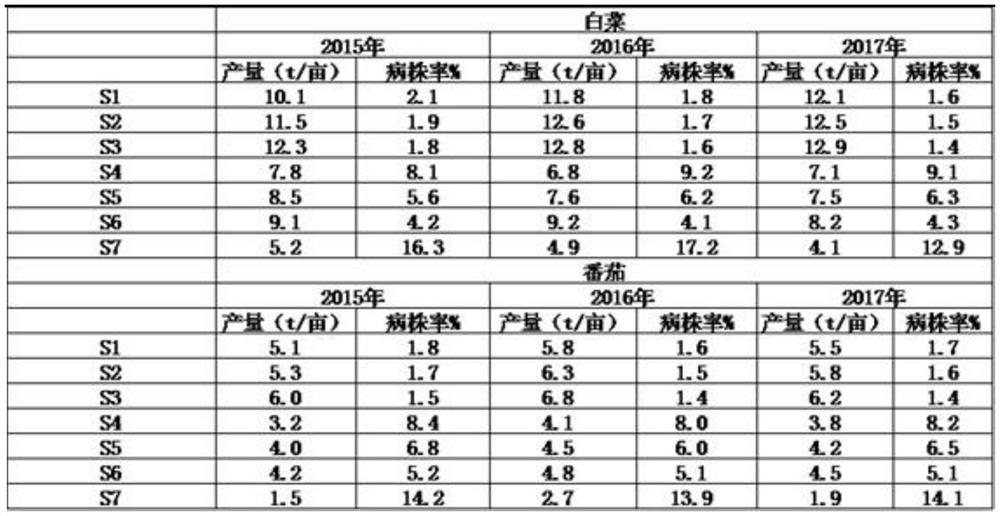

A kind of ginkgolic acid-rhamnolipid compound fungicide and its preparation method and application

InactiveCN109258703BAchieve antibacterial and antibacterial effectAbundant resourcesBiocideFungicidesRoot growthHouttuynia

The invention discloses a ginkgolic acid-rhamnolipid compound bactericide, a preparation method and application thereof, and belongs to the technical field of pesticides. The invention is prepared from the following raw materials in parts by weight: 15-25 parts of ginkgolic acid extract, 10-15 parts of rhamnolipid, 3-5 parts of synergist, 1-3 parts of wetting agent, and dispersant 1-3 parts, 0.5-1 parts of preservatives, 0.5-0.8 parts of antifreeze and 10-15 parts of fillers. The invention adopts the combination of membrane technology and macroporous adsorption resin to separate and purify the ginkgolic acid, and realizes the high-efficiency extraction of the ginkgolic acid. The present invention adds houttuynia cordata and bamboo vinegar liquid as synergists, and the two cooperate with each other to promote the fungicide of the present invention to exert the bactericidal effect, and meanwhile, the bamboo vinegar also has the effect of promoting the germination, rooting and growth of crop seeds and improving crop yield. The invention selects discarded ginkgo leaf waste residue and outer testa as raw materials to prepare the fungicide, which reduces the use of chemical pesticides and reduces environmental pollution.

Owner:LINYI UNIVERSITY

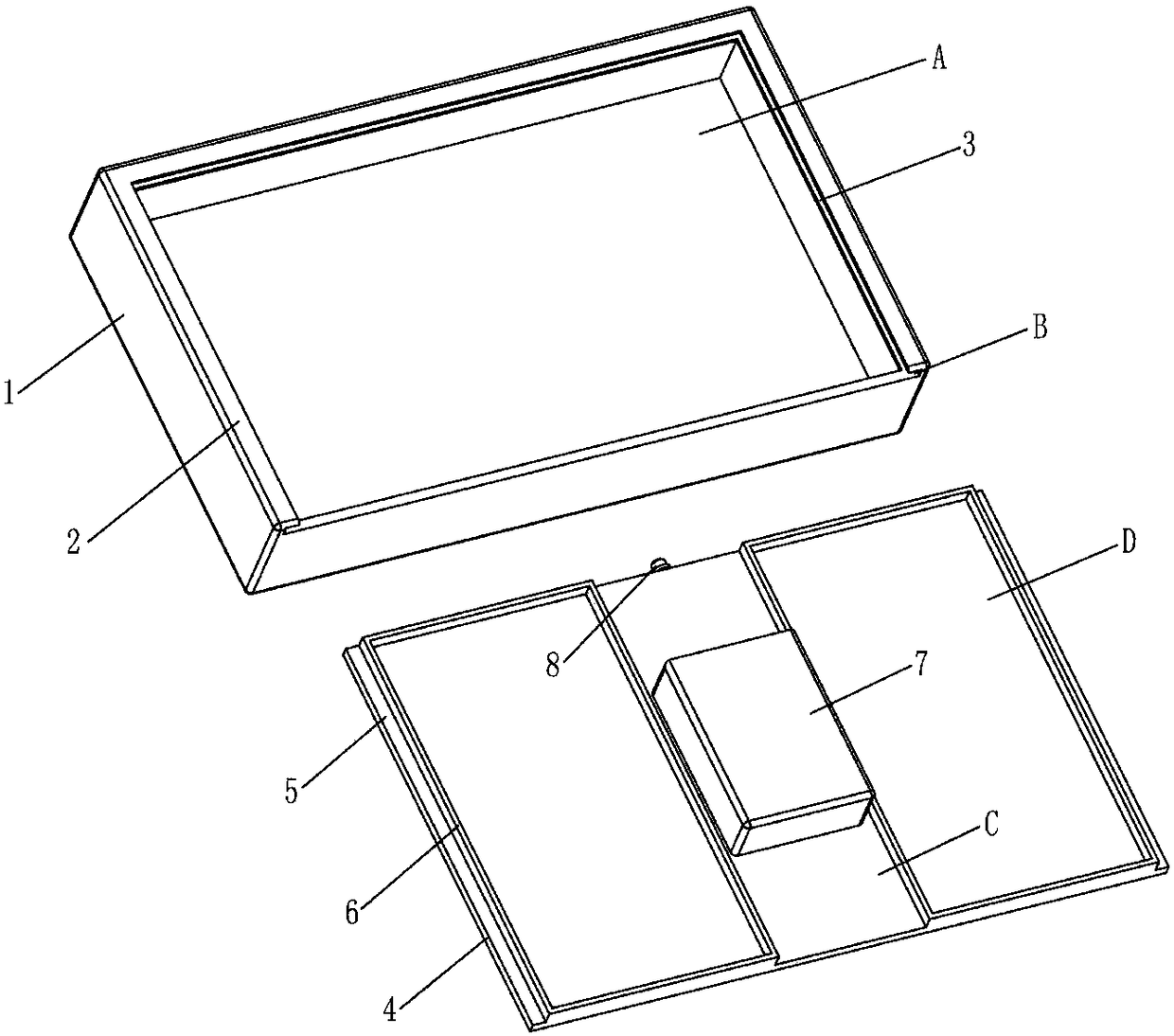

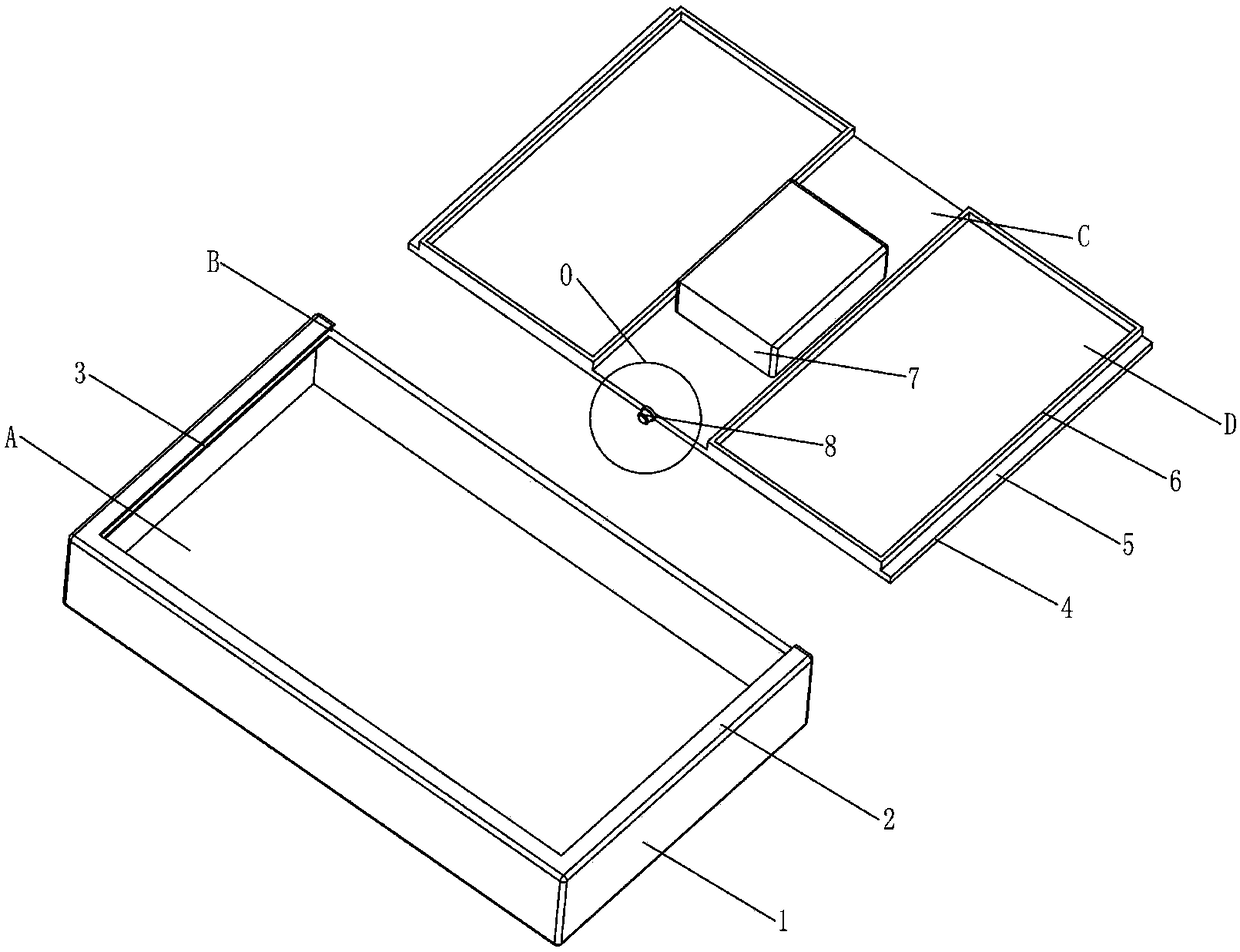

A pull-out cigarette case with video promotion function

ActiveCN106800129BGuaranteed practicalityRaise the gradeContainers for flexible articlesPackaging cigaretteVideo advertisingPressure sensor

The invention discloses a pulling type cigarette case with a video advertising function. The pulling type cigarette case comprises a case body, a case cover, screen mounting frames, a control box and a pressure sensor, wherein a mounting space is formed inside the case body; the top of the mounting space is an open surface; a sliding chute is formed in the inner side wall of the case body; the case cover is inserted into the sliding chute from the front side of the sliding chute; the control box is arranged on the case cover; a display control assembly is arranged in the control box; the screen mounting frames are fixed on the case cover, and are located on two sides of the control box; display screens are embedded into the screen mounting frames; the pressure sensor is fixedly arranged on the rear side wall of the case cover; when the case cover is inserted into the case body, the pressure sensor is pressed against the inner side wall of the case body; when a circuit switch is turned on, the case cover is pulled out, and the pressure sensor gets away from the inner side wall of the case body along with the case cover; when the circuit switch is turned off, the display assembly controls the display screens to play pre-stored video information. By the adoption of the design of a pulling type structure, the pulling type cigarette case is integrated with a video playing function, so that the practicability is guaranteed, and the advertising effect is effectively enhanced.

Owner:威海神舟信息技术研究院有限公司

A voice interaction method, device, storage medium and air conditioner

ActiveCN109903755BVersatileImprove experienceMechanical apparatusSpace heating and ventilation safety systemsSpeech soundSmart device

Owner:GREE ELECTRIC APPLIANCES INC

Preparing method of water hyacinth fermented protein powder

InactiveCN108559712AResource maximizationImprove economyFungiYeast food ingredientsMonopotassium phosphateWater Hyacinths

The invention discloses a preparing method of water hyacinth fermented protein powder. The preparing method comprises the following steps that firstly, by weight, 80 parts of water hyacinth is dried at the temperature of 45 DEG C until the water content is 65%, and then smashing is conducted; secondly, by weight, 20 parts of bran is added into the smashed water hyacinth obtained in the first step;thirdly, 1% of nutritive salt solution is added into the mixture obtained in the second step, wherein the nutritive salt solution comprises 0.08% of ammonium sulfate, 0.12% of monopotassium phosphate, 0.05% of magnesium sulfate and 100 ml of water; fourthly, the mixture obtained in the third step is heated at the temperature of 121 DEG C for 20 min for sterilization, and a culture medium is prepared; fifthly, aspergillus niger, geotrichum candidum and yeast are inoculated into the mixture obtained in the fourth step in the ratio of 1:1.5:1.5 at the temperature of 28 DEG C, and closed cultureis conducted for 72 hours. According to the characteristics of the water hyacinth, the yeast, the aspergillus niger and the geotrichum candidum are selected for fermentation in the specific proportion, and water hyacinth resources are utilized maximumlly.

Owner:CHONGQING SHENGSHUN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com