Spark plug auxiliary gasoline compression ignition combustion chamber

A technology of spark plugs and combustion chambers, which is applied in the field of reciprocating piston engines, can solve problems such as small cylinder diameters, and achieve the effects of improving combustion stability and combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

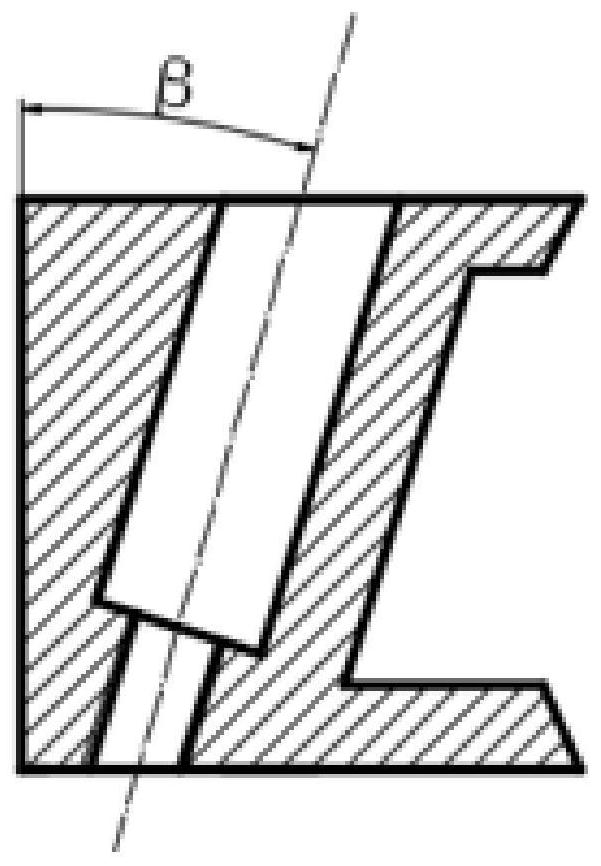

[0012] In order to better understand the content and features of the present invention, the technology of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

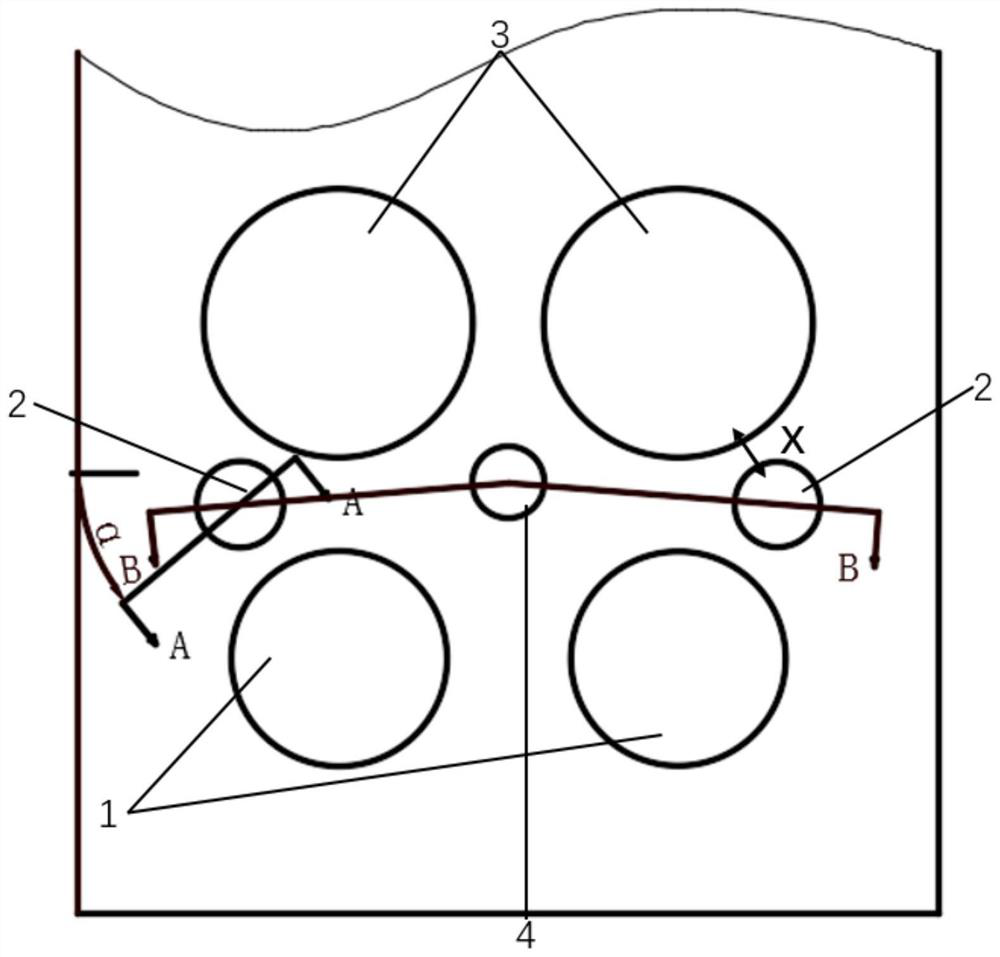

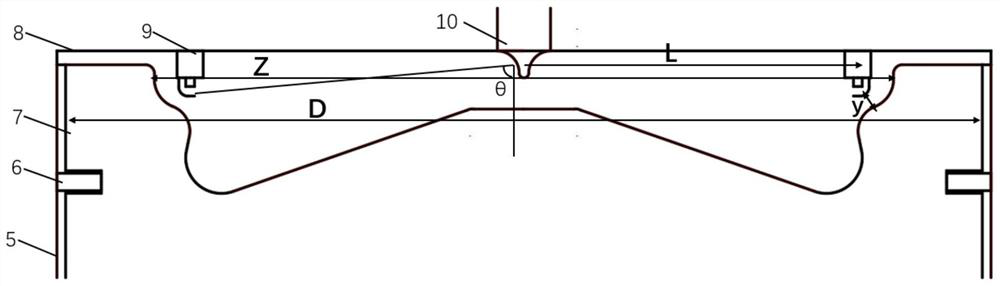

[0013] As shown in the accompanying drawing, the improvements made are explained by taking a six-cylinder diesel engine as an example. The top surface of the six-cylinder block is equipped with multiple cylinders sharing a cylinder head. figure 1 It is a schematic bottom view of part of the cylinder head at the sixth cylinder, and the structure of the other five cylinders is the same as that of the sixth cylinder.

[0014] The invention is an improvement on the basis of the existing heavy-duty multi-cylinder diesel engine, and is based on the existing diesel engine combustion chamber. Spark plug-assisted gasoline compression ignition combustion chambers include but are not limited to single-cylinder engines. When used on multi-cylinder engines, they refer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com