Fried crisp chilies and preparation process thereof

A technology of pastry and technology, which is applied in the field of pastry pepper and its preparation, can solve the problems of affecting the color and fragrance of pastry pepper, endangering human health, and producing burnt smell, etc., and achieves the effect of excellent color, easy control, and suitable time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, the preparation of deep-fried dried capsicum

[0030] Raw materials: Dried Chili peppers available in the market, red in color, free from insects, mildew, and damage.

[0031] Preparation method: Take 1.5kg of dried peppers, wash them with clean water, dry them, cut off the fruit stalks, and cut them into small pieces with a length of about 1cm. Take 500 g of dried chilies cut into small sections, place them in an automatic temperature-controlling pastry pan filled with vegetable oil, fry them at 170° C. for 40 seconds, take them out, and obtain the fried dried peppers. Among them, the mass-volume ratio of the dried chili to the vegetable oil in the automatic temperature-controlling pastry pan is 1:3g / mL.

[0032] The beneficial effects of the present invention are demonstrated through experimental examples below.

experiment example 1

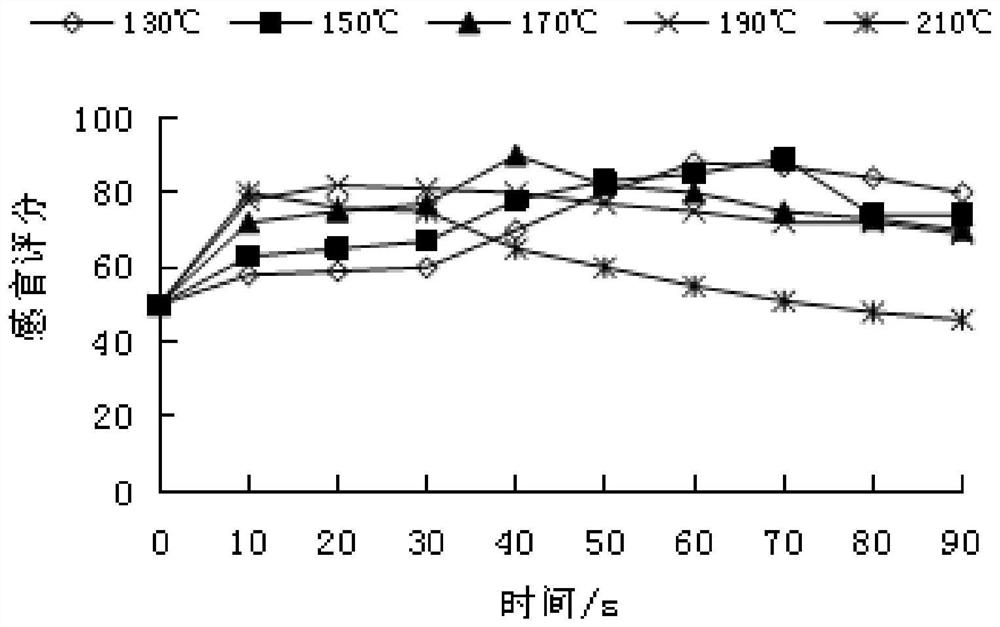

[0033] Experimental example 1, screening experiment of pastry technology

[0034] 1. Experimental method

[0035] Using the preparation method of Example 1, the oil temperature in the automatic temperature-controlling pastry pan is respectively controlled to 130°C, 150°C, 170°C, 190°C, and 210°C, with 10s as the interval period of the pastry gradient and 90s as the end time of the experiment (the rest Condition is identical with embodiment 1), prepares the dried chilli of fried pastry gained under different pastry temperature and time.

[0036] Then 78 college students majoring in food were randomly selected to conduct a comprehensive sensory evaluation and analysis on the color and characteristic aroma of the obtained crispy dried peppers. The total score is 100 points. The scoring standards are shown in Table 1.

[0037] Table 1 Sensory Comprehensive Scoring Criteria

[0038]

[0039] 2. Experimental results

[0040] For the results of the sensory comprehensive score, ...

experiment example 2

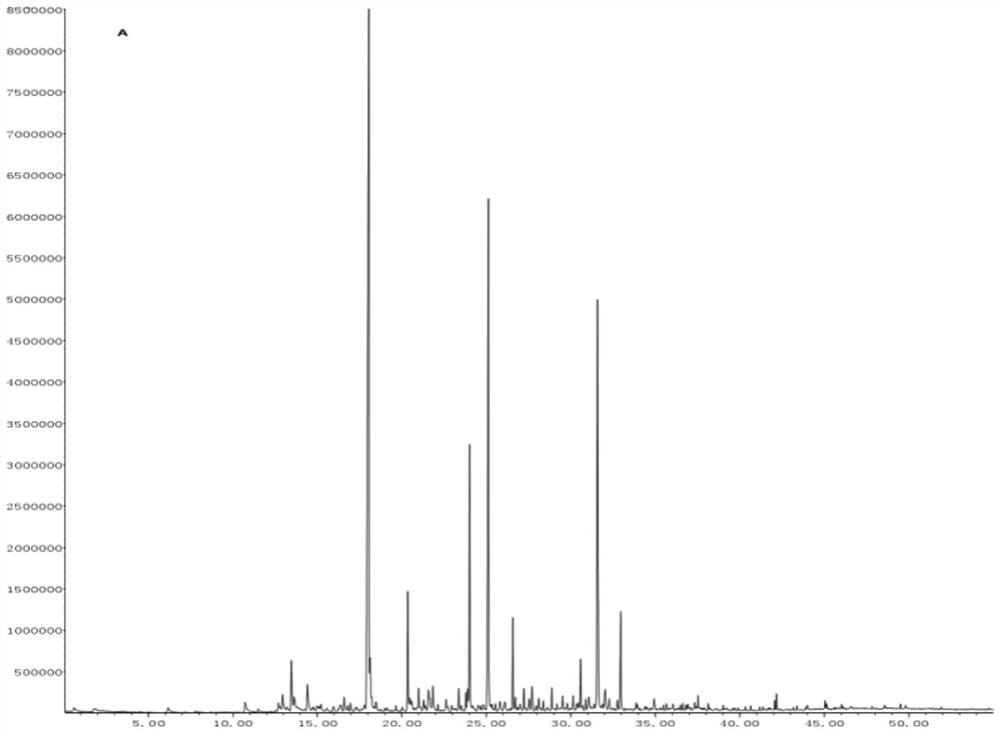

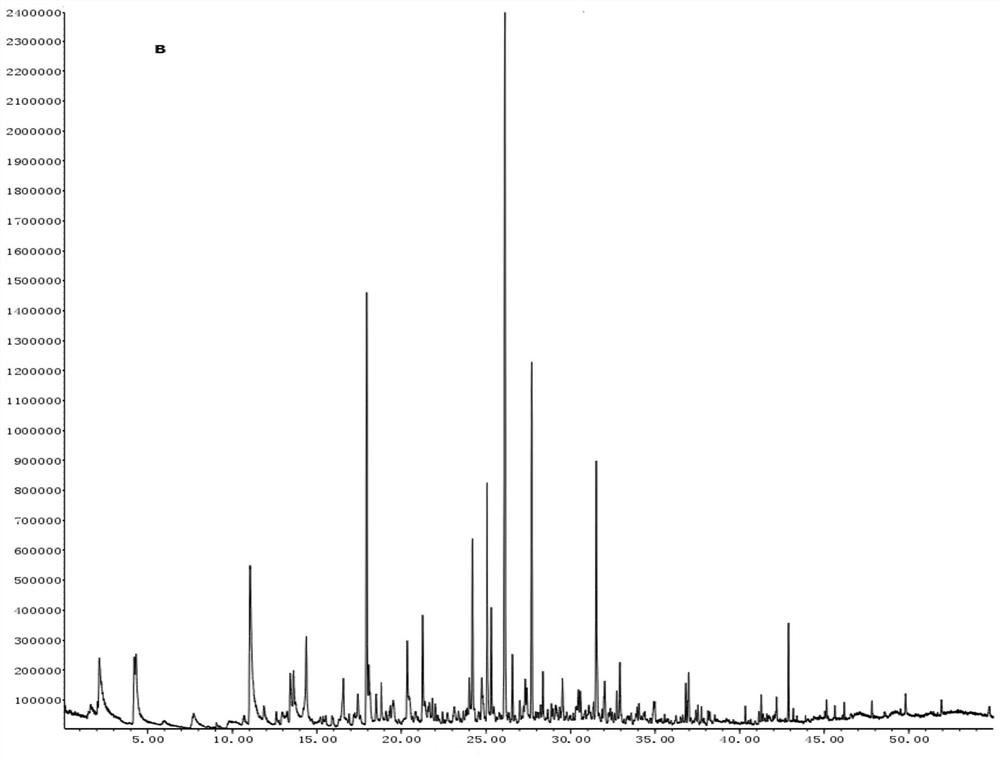

[0042] Experimental example 2, comparison of volatile components of raw material dried chili and fried dried chili

[0043] 1. Experimental samples

[0044] (A) dried capsicum cut into small sections in embodiment 1;

[0045] (B) adopt the preparation method of embodiment 1, control the pastry temperature to be 170 DEG C, the pastry dried chili that the pastry time is 40s to make;

[0046] (C) adopt the preparation method of embodiment 1, control the pastry temperature to be 210 ℃, the pastry dried chili that the pastry time is 90s to make;

[0047] (D) Using the preparation method of Example 1, controlling the temperature of the pastry to be 150° C., and the pastry time to be 70 s to prepare the pastry dried chilies.

[0048] 2. Experimental method

[0049] Experimental equipment: solid phase microextraction apparatus (HP-1510, including 65 μm PDMS / DVB extraction head, Supelco Company, USA); gas chromatography-mass spectrometry (GC-MS, Agilent 7890B / 5977A, Agilent Company,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com