Self-expanding umbrella skirt-shaped printing and dyeing waste gas treatment device

A waste gas treatment device and self-expanding technology, which are applied in the fields of combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of increased processing cost of printing and dyeing waste gas, large damage rate of filter components, and easy blockage of filter screen, etc. Cost input, improve protection, improve the effect of interception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

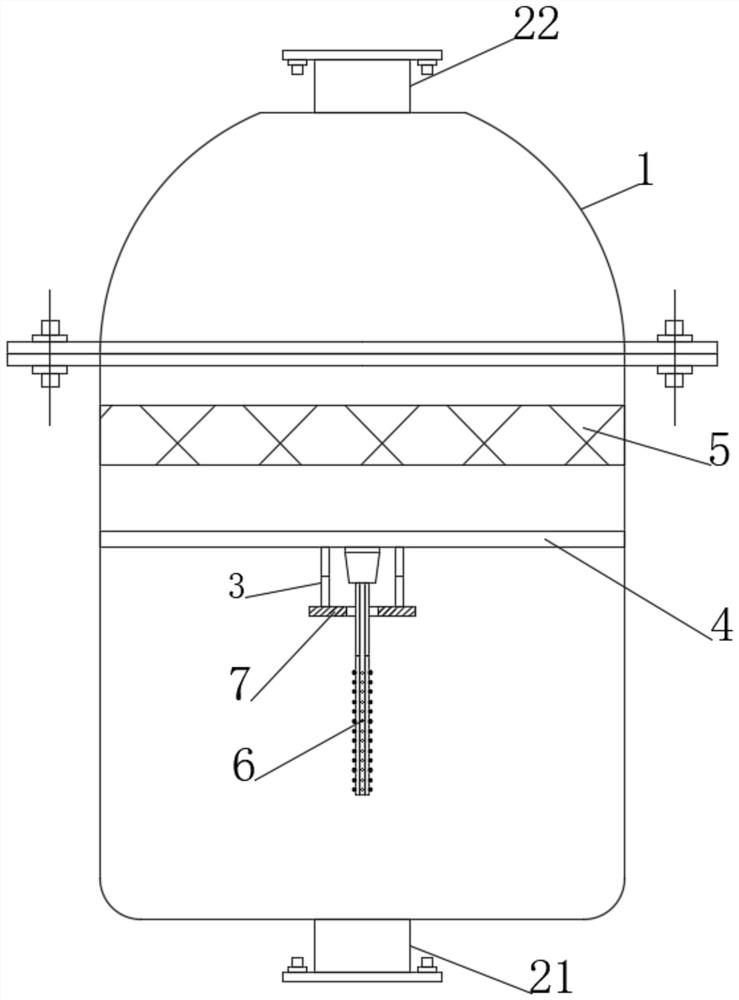

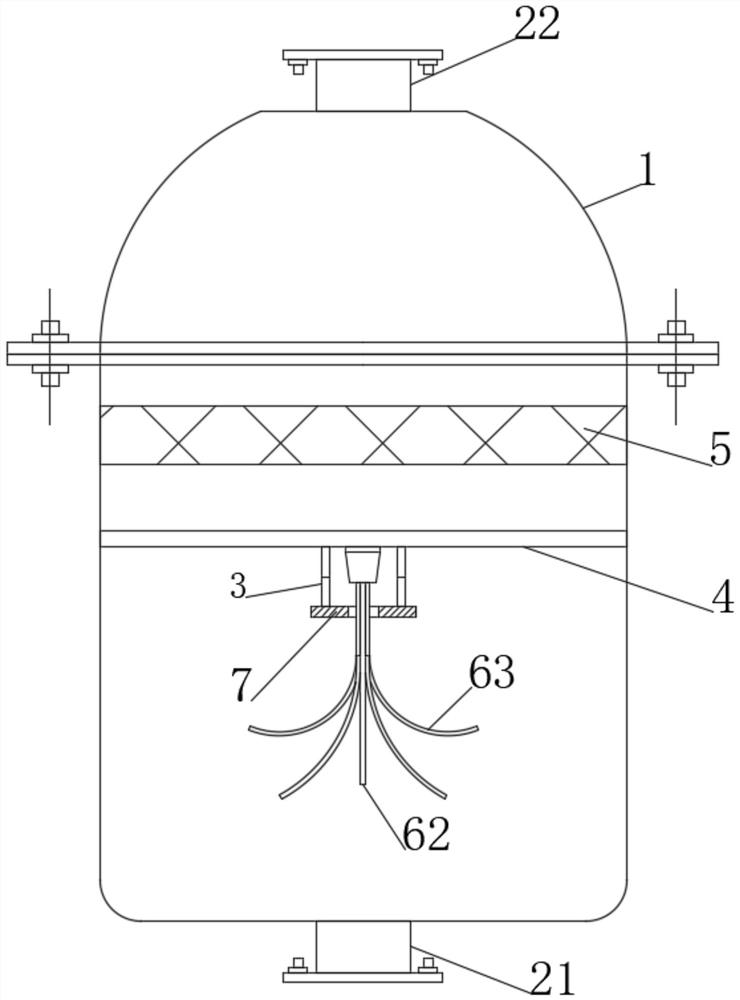

[0039] see figure 1 , a self-expanding umbrella skirt-shaped printing and dyeing waste gas treatment device, including a device body 1, the upper and lower ends of the device body 1 are respectively fixedly connected with an air outlet pipe 22 and an air inlet pipe 21, and both the air inlet pipe 21 and the air outlet pipe 22 communicate with the inside of the device body 1 , the device body 1 is fixedly connected with a filter component 5, and the device body 1 is also fixedly connected with a grid plate 4, the grid plate 4 is located below the filter component 5, and the lower end of the grid plate 4 is fixedly connected with a self-expanding interception column 6. The outer end of the upper part of the extended interception column 6 is provided with a fluff-removing ring 7, and two mutually symmetrical electric push rods 3 are fixedly connected between the upper end of the fluff-removing ring 7 and the grid plate 4.

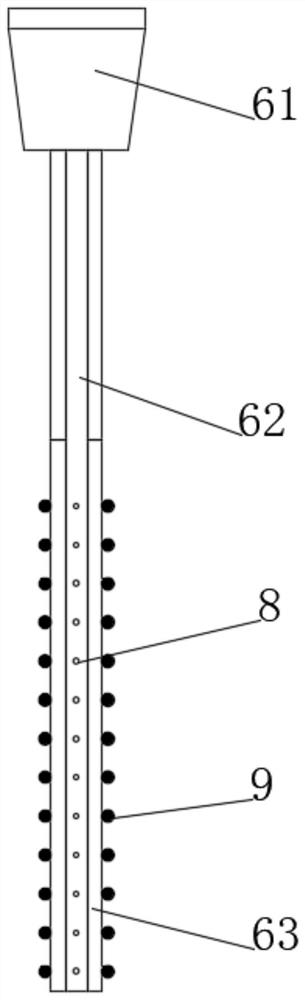

[0040] see image 3 The self-expanding interception col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com