Continuous intermittent grain particle grinding device

A grain grain, intermittent technology, applied in grain processing and other directions, can solve the problems of poor processing quality, inefficiency, low efficiency of corn grain milling equipment, etc., and achieve high work efficiency, simple structure and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

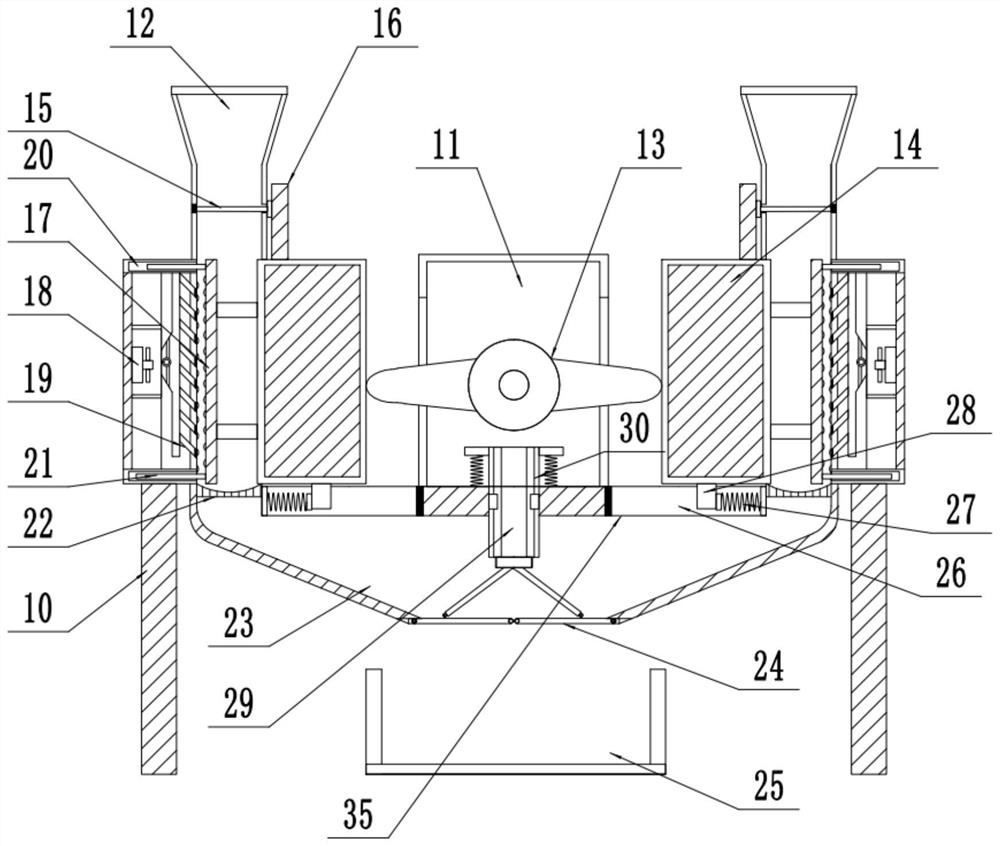

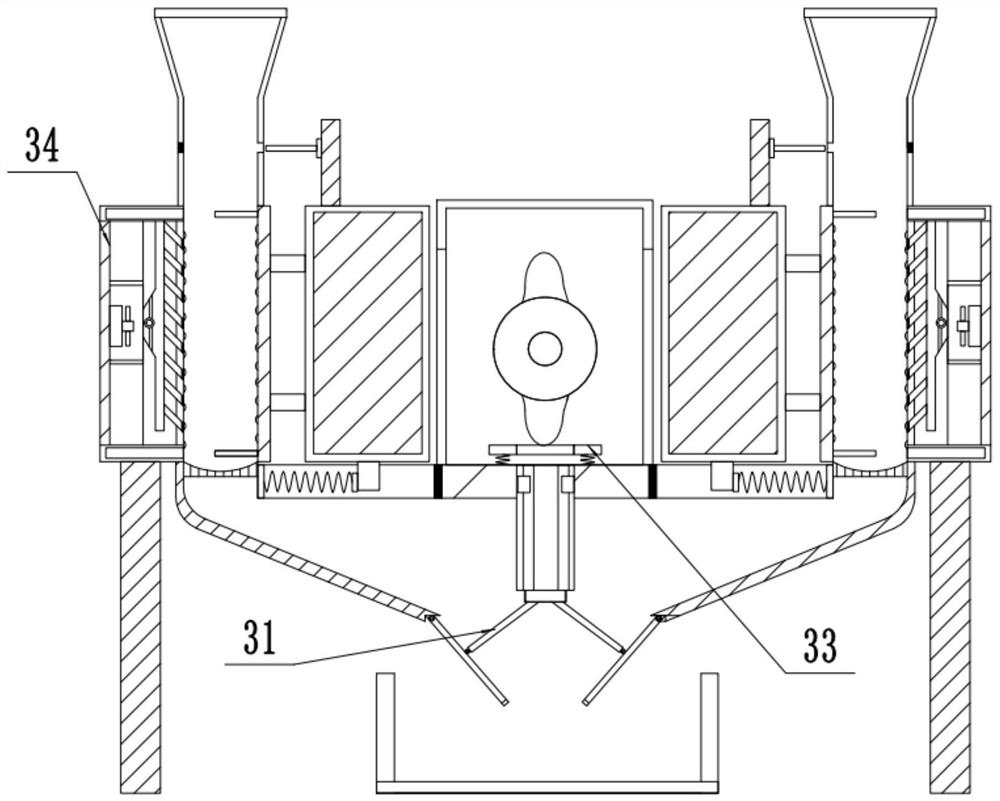

[0021] see Figure 1-3 , a continuous intermittent grain grinding device, comprising a foot 10, a feed channel 12, a material delivery channel 23, a powder collection tank 25, a bottom plate 35; A group of two-way cams 13 are arranged inside the cavity 11, and the rear center of the two-way cams 13 is rotatably connected with a rotating motor fixed on the rear side wall of the driving cavity 11. The position of the opening and closing of the chamber wall is provided with a sliding port for the end of the two-way cam 13 to pass through. There are two groups of push blocks 14 arranged symmetrically on the outside of the sliding ports on the left and right sides. In the transverse slide groove 26 inside the upper side of the base plate 35 , an anti-collision pad is fixedly installed at the inner end of the side of the transverse slide groove 26 near the center of the drive cavity 11 . The side of the slide block 28 away from the center of the drive chamber 11 is elastically conn...

Embodiment 2

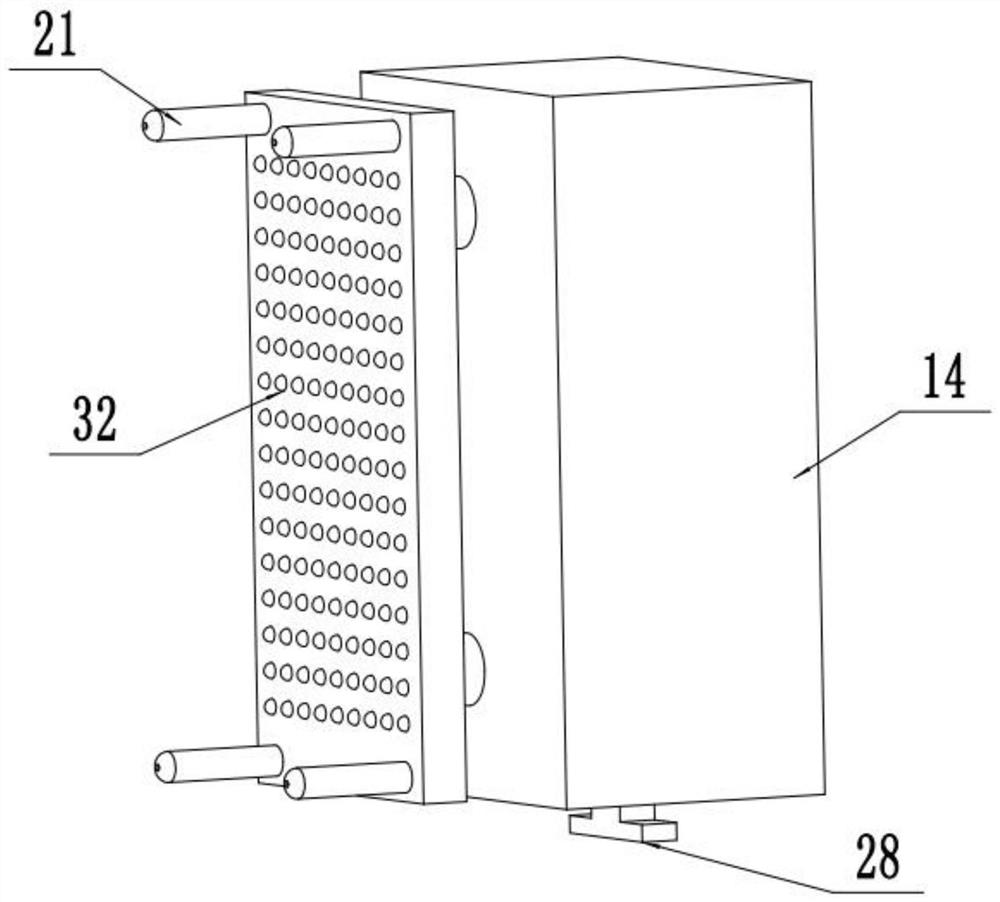

[0024] On the basis of Embodiment 1, a group of fans 18 are arranged inside the fixed rolling plate 34, and the output end of the fan 18 is connected to the side of the moving rolling plate 17 through an air pipe to the side of the fixed rolling plate 34. On the air outlet pipe 19 in the wall, the air outlet pipe 19 is set as an inclined structure that is high inside and low outside, and the air is delivered to the area between the fixed rolling plate 34 and the moving rolling plate 17 through the air outlet pipe 19, so that The powdery grain sticking to the fixed rolling plate 34 sidewall and the mobile rolling plate 17 outer wall is blown down, and the powdery grain will not enter the inside of the fixed rolling plate 34 .

[0025] The working principle of the present invention is: at first when the two-way cam 13 inside the drive cavity 11 is in the state of stopping, the fixed rolling plate 34 is in a separate state from the moving rolling plate 17, and when the grain parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com