Multi-waveform electromagnetic field assisted permanent magnet grinding machining device and using method thereof

A technology of grinding processing and electromagnetic field, which is applied in grinding drive devices, metal processing equipment, machine tools suitable for grinding workpiece edges, etc. Reduce the magnetic flux leakage problem, facilitate self-renewal, and release the effect of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

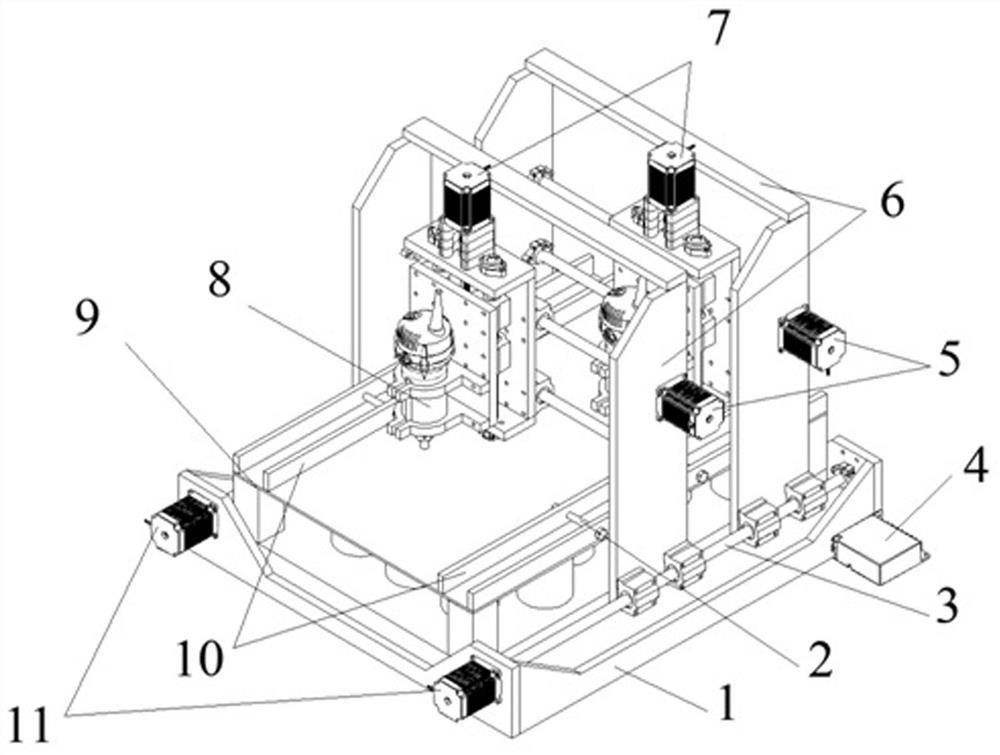

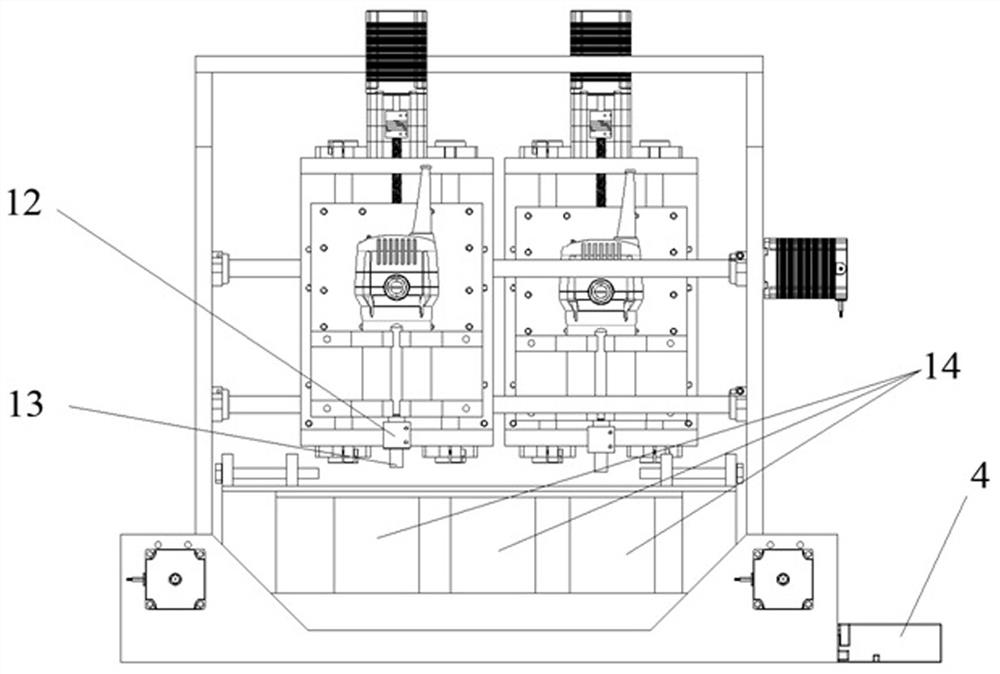

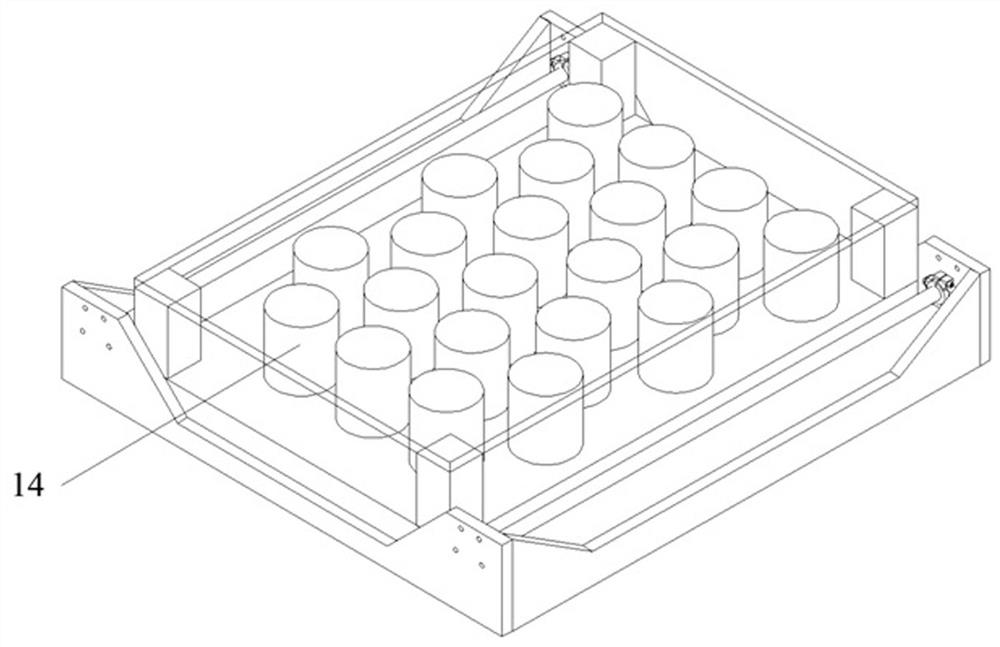

[0024] Such as Figure 1-4 As shown, the multi-waveform electromagnetic field assisted permanent magnet grinding processing device of the present invention is characterized in that it includes a bottom plate 1, two Y-axis screw screws 3 arranged on both sides of the bottom plate 1 drive the two Y-axis screw screws 3 respectively Two Y-axis motors 11, two gantry frames 6 arranged on the two Y-axis lead screws 3, an X-axis lead screw arranged on each gantry 6 and an X-axis motor driving the X-axis lead screws 5. The Z-axis lifting device arranged on each gantry 6, the rotary motor 8 provided on the Z-axis lifting device, the permanent magnetic pole 13 connected to the output shaft of the rotary motor 8 through a coupling 12, set The electromagnet group 14 on the base plate 1, the DC power supply 4 connected with this electromagnet g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com