Self-compacting soil, preparation method thereof and construction method for backfilling municipal cavity

A construction method and self-compacting technology, applied in construction, road, road repair and other directions, can solve the problems of difficulty in rolling, compacting and compacting the axillary angle of backfill, poor bonding effect of undisturbed soil, and high manufacturing cost of backfill materials. Save the cost of spoil transportation, save the project cost, and have a good effect of backfilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The embodiment of the present invention provides a preparation method of self-compacting soil, comprising the following steps:

[0040] S10. Obtain undisturbed soil, and after performing desilting and impurity removal treatment on the undisturbed soil, measure the moisture content of the undisturbed soil;

[0041] S20. Obtain cement, the mass ratio of the cement to the dry soil in the undisturbed soil is 1: (3-4);

[0042] S30. Obtain water, so that the ratio of the total mass of the dry soil in the cement and the undisturbed soil to the total mass of the water in the self-compacting soil is 1: (1.5-2.5);

[0043] S40. Obtain additives, the amount of which is 0.3% to 1.0% of the cement quality;

[0044] S50. The undisturbed soil, the cement, the water and the additive are mixed and stirred according to the ratio to obtain self-compacting soil.

[0045] In the method for preparing self-compacting soil provided by the embodiment of the present invention, the moisture co...

Embodiment 1

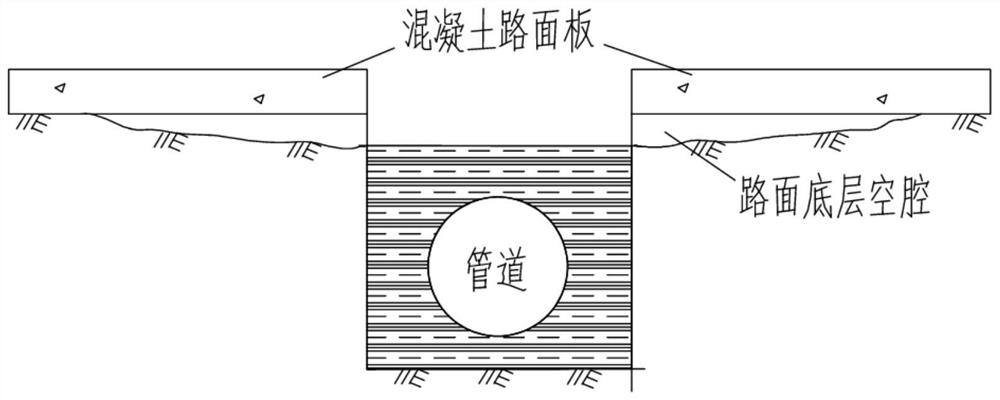

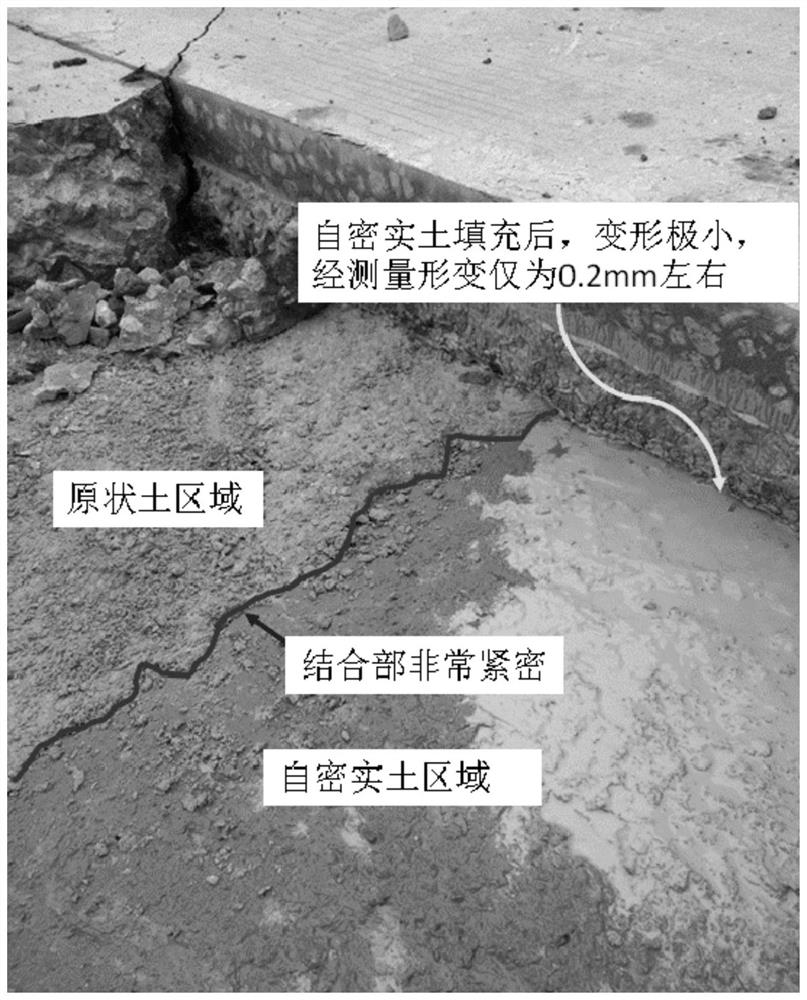

[0080] A kind of self-compacting soil backfilling the pavement bottom cavity formed by the excavation of the Shajing River sewage interception project in the Maozhou River Basin in Bao'an District, Shenzhen.

[0081]①Project overview: During the implementation of the pipeline network project of the Shenzhen Maozhou River (Baoan Area) water environment comprehensive improvement project, the geological conditions in the pipeline network laying area are complex, mainly consisting of silty soil, miscellaneous fill soil and sandy soil. This sub-item is located in the administrative area of Songgang Street, Baoan District, Shenzhen. The project content mainly includes the construction of the Shapu area of Songgang Street, the Hongxing and Dongfanghong areas of Songgang Street, the construction of the rainwater and sewage pipe network in the area west of Songgang Avenue, Lougang, Songgang Street, and The construction of the connection and improvement project of the sewage pipe net...

Embodiment 2

[0086] A kind of self-compacting soil backfilling the pavement bottom cavity formed by the excavation of the comprehensive improvement project of the pond's downwelling in the Maozhou River Basin in Bao'an District, Shenzhen.

[0087] ①Project overview: During the implementation of the pipeline network project of the Shenzhen Maozhou River Water Environment Comprehensive Improvement Project, the pipeline network construction is widely distributed and the geological conditions in the construction area are complex. This sub-item is located in the administrative area of Songgang Street, Baoan District, Shenzhen. The project mainly includes Yanchuan Village Area of Songgang Street, Tangxiayong Industrial Area of Songgang Street, Tangxiayong Area of Songgang Street, and rainwater and sewage diversion pipes of Hongqiaotou Area of Songgang Street The construction of the network, and the construction of the reclaimed water replenishment project of the Songgang Water Purificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com