Production method of single-dyed polyester cotton blended yarn

A polyester-cotton blending and production method technology, applied in yarn, textile and papermaking, etc., can solve the problems of high risk of quality compensation, difficult to remove fiber defects, etc., to improve the mixing effect, reduce neps defects, low severity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

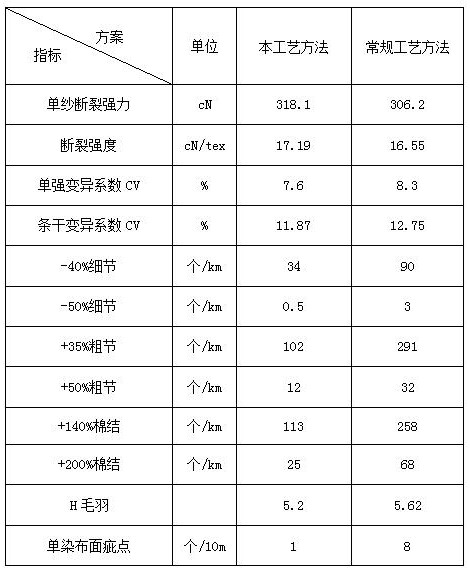

Image

Examples

Embodiment Construction

[0009] 1. Preparation of polyester / cotton blended single-dyed yarn with a linear density of 18.5tex and a JC / T blending ratio of 50 / 50:

[0010] 1. Cotton distribution:

[0011] The principle of cotton fiber matching: choose 3.5 grade cotton.

[0012] The principle of cotton distribution emphasizes quality first, overall arrangement, overall consideration, guaranteeing key points, looking forward and backward, keeping a steady flow, thoroughly understanding both ends, and rational allocation; On the basis of many varieties of production, according to different quality requirements, it can not only ensure the use of cotton for key varieties, but also make overall arrangements; looking ahead is to fully consider the situation of raw cotton in stock, semi-finished products in the workshop, and raw cotton procurement to ensure supply; It is to prolong the use period of each batch of raw cotton as much as possible, and strive to achieve multi-mark production, at least 6-8 marks; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com