A Vacuum Auxiliary Nozzle Mechanism for Air-jet Textile Machine

An auxiliary nozzle and vacuum technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of wasting more time, complicated replacement of nozzles, fine-tuning nozzles, etc., and achieve the effect of preventing air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

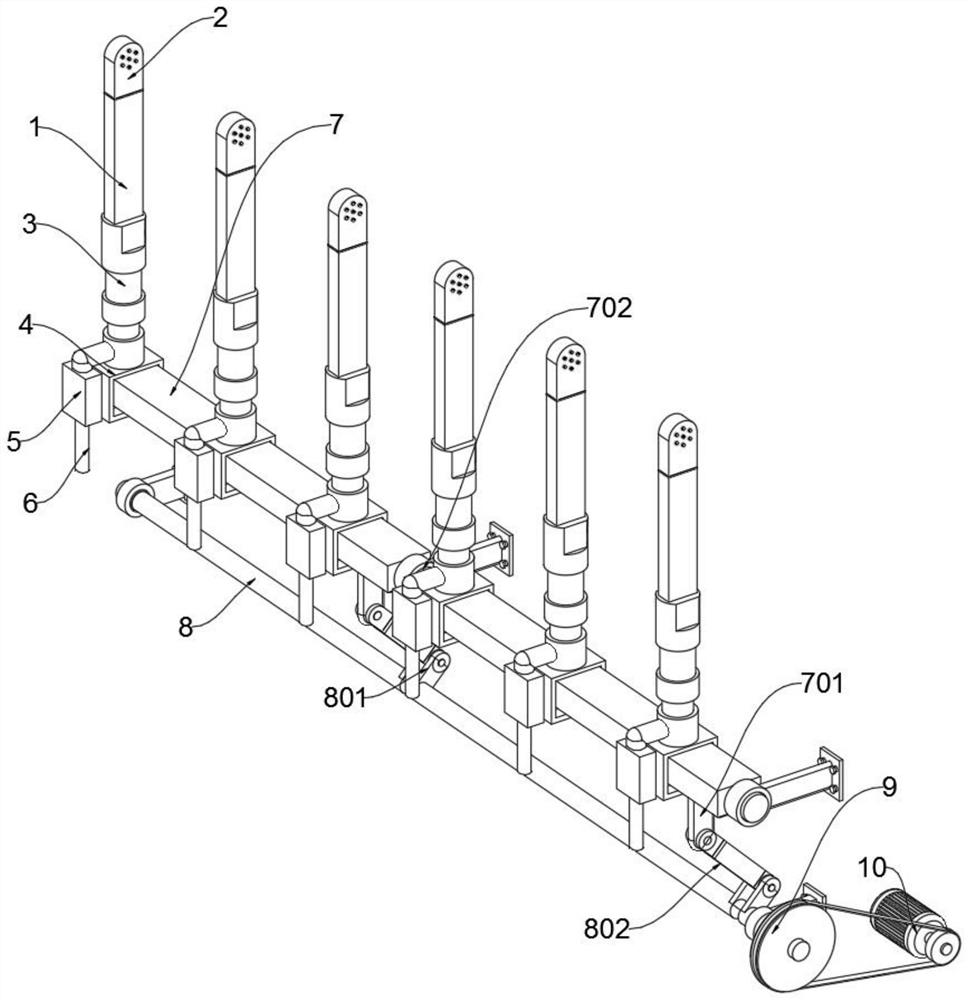

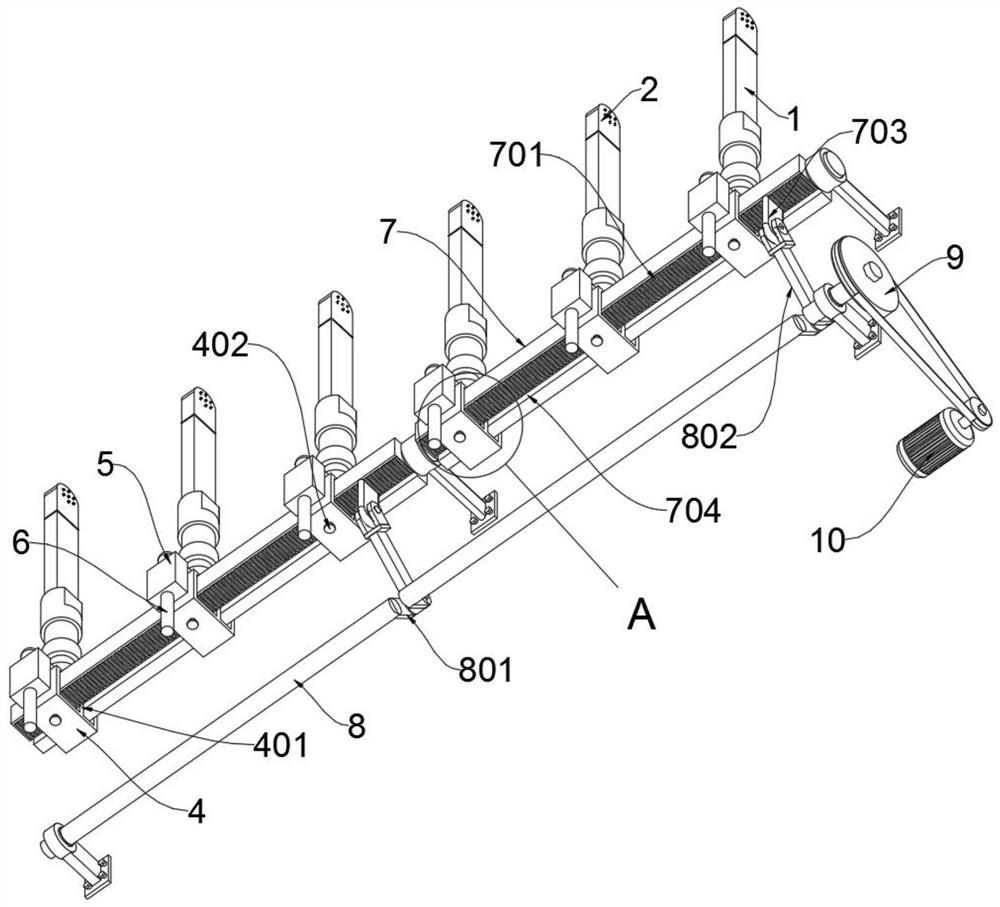

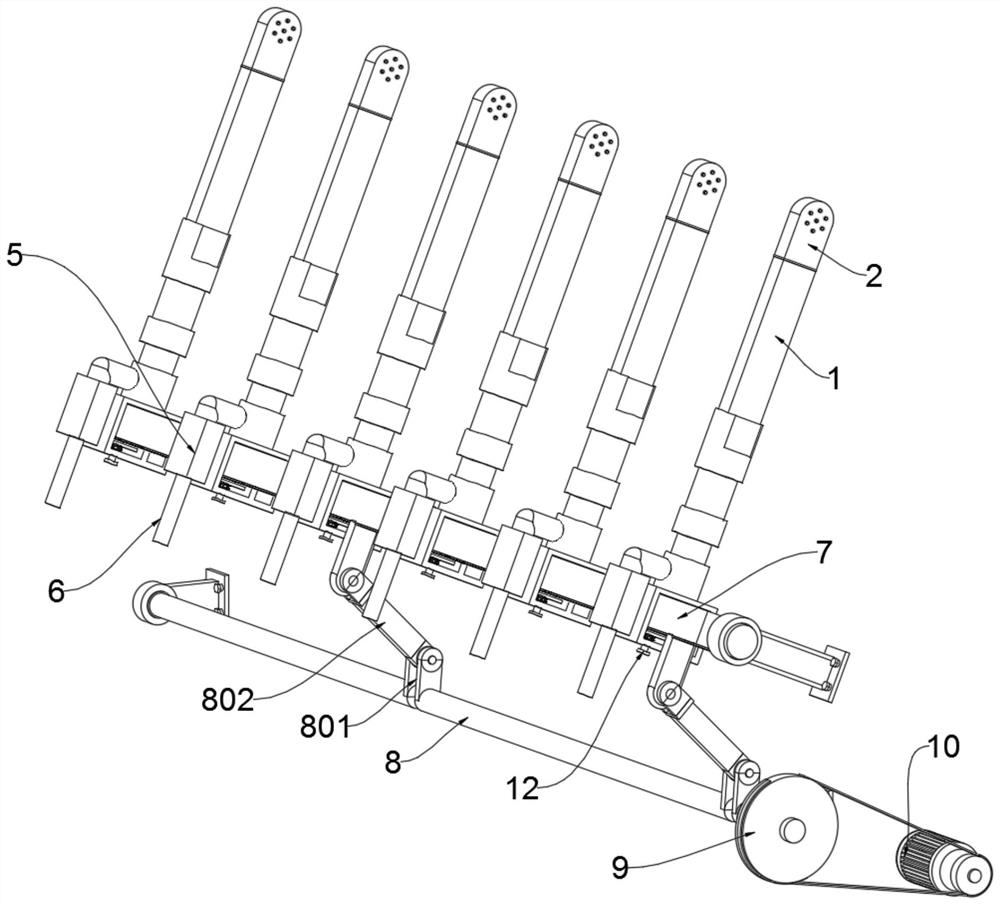

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034]The present invention provides a vacuum auxiliary nozzle mechanism for an air-jet textile machine, which includes a lower auxiliary nozzle 1, an air delivery seat 3, a slider seat 4, a rotating base 7, a crankshaft 8, a driving device 10, an isolation mechanism 11, and a locking plate 12 The upper part of the lower auxiliary nozzle 1 is movably connected with the upper auxiliary nozzle 2; the air delivery seat 3 is fixedly connected under the lower auxiliary nozzle 1, and the air delivery seat 3 is connected with the output end of the pneumatic control valve 5; the input end of the pneumatic control valve 5 The intake pipe 6 is fixedly connected; the slider seat 4 is fixedly connected to the lower end of the air delivery seat 3; the slider seat 4 is slidably connected to the rotating base 7; the top of the crankshaft 8 is movably connected to the rocker 703 below the rotating base 7; The output end of the drive d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com