Rib plate framework concrete cast-in-place slab

A concrete and cast-in-place slab technology, applied in the field of concrete cast-in-place slabs, can solve problems such as heavy workload, affecting project progress, and tediousness, and achieve the effects of improving bending bearing capacity, saving manpower and time, and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

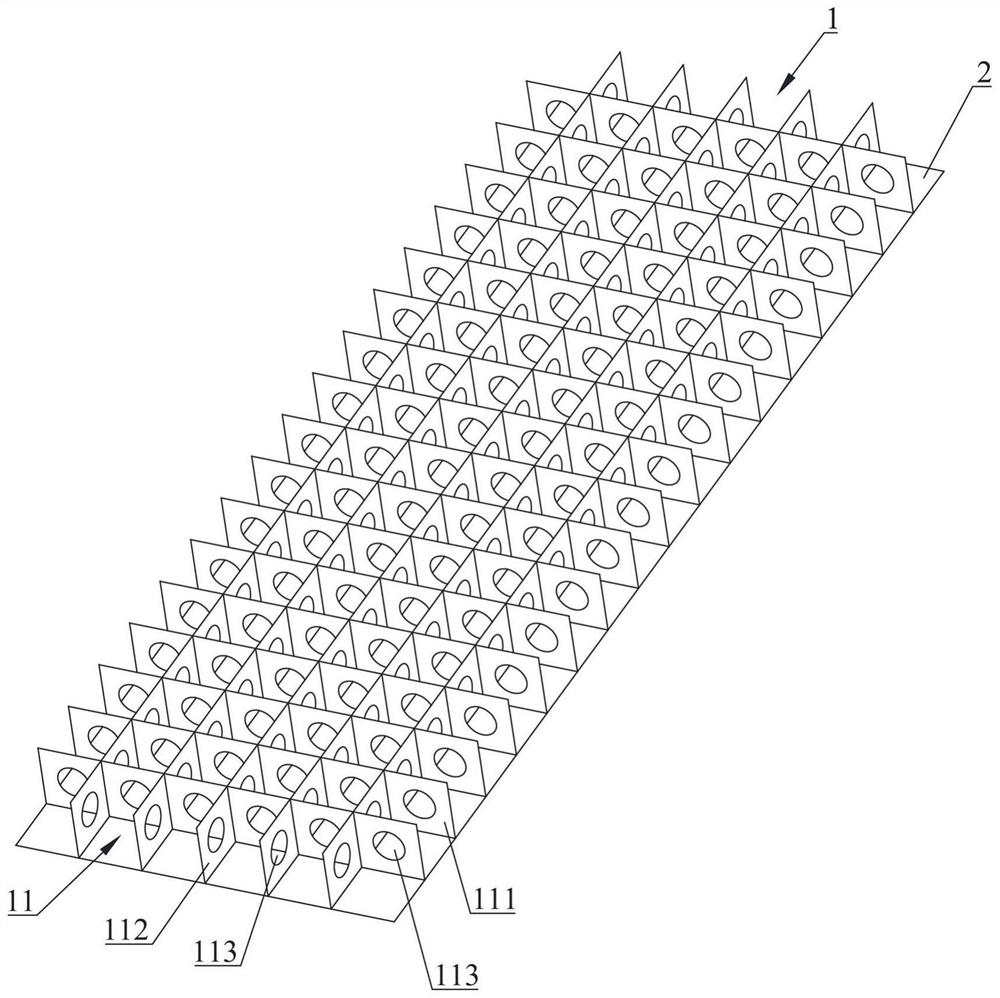

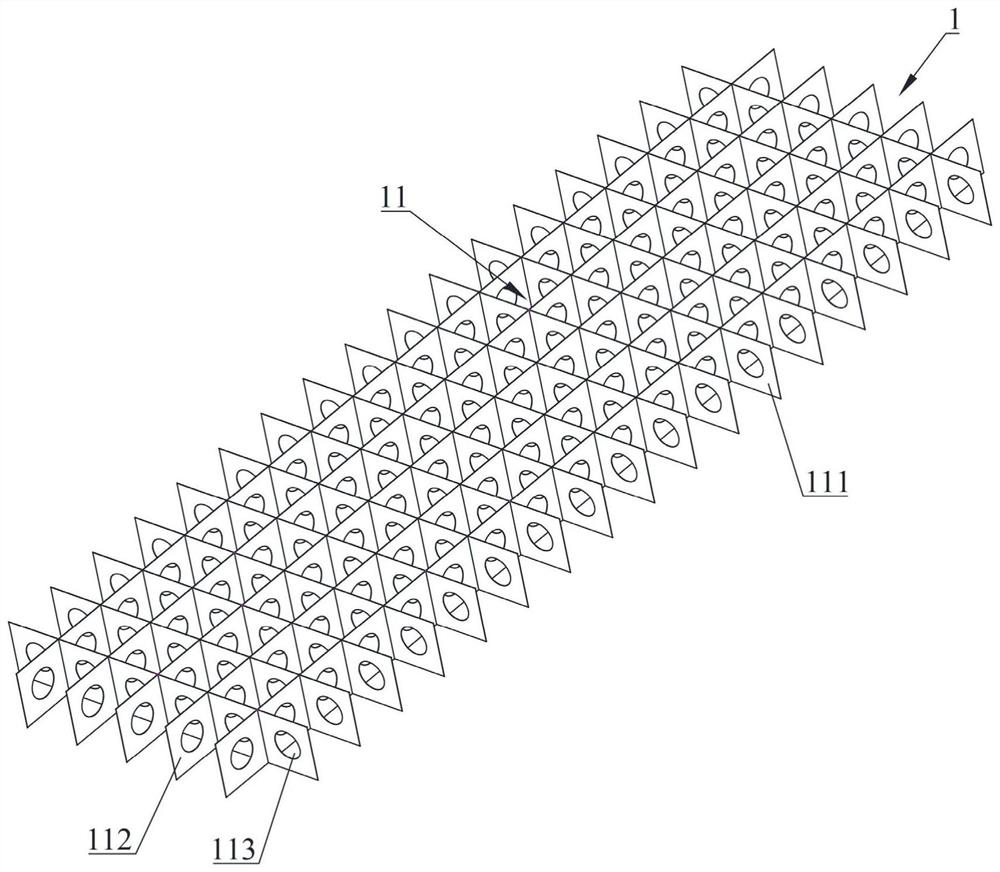

[0037] see Figure 1-3 As shown, the rib frame concrete cast-in-situ slab provided by the embodiment of the present invention includes a rib frame 1 , a bottom plate 2 and concrete 3 .

[0038] see figure 1 and figure 2 As shown, the rib frame 1 includes a plurality of transverse ribs 111 and a plurality of longitudinal ribs 112, wherein, in a preferred embodiment, the plurality of transverse ribs 111 are arranged in parallel and at intervals, and the plurality of longitudinal ribs 112 Parallel spacing between settings. A plurality of transverse ribs 111 and a plurality of longitudinal ribs 112 are criss-crossed to form a plurality of pouring units 11 . In some embodiments, the casting unit 11 may have a square cross section, that is, the distance between adjacent transverse ribs 111 is the same as the distance between adjacent longitudinal ribs 112 . There is a connecting channel 113 between adjacent casting units 11 to communicate with two adjacent casting units 11 , an...

Embodiment 2

[0047] see Figure 5 As shown, the second embodiment provides a more preferable connection structure between the transverse ribs 111 and the longitudinal ribs 112. In one embodiment, the lower side of the longitudinal ribs 112 is provided with a plurality of lower interlocking grooves 1121 at intervals. The distance between two adjacent lower interlocking grooves 1121 is the same as the distance between two corresponding adjacent transverse ribs 111, so that the two adjacent transverse ribs 111 can be inserted into two adjacent lower ribs. Embedding lock groove 1121 . The upper side of the transverse rib 111 is provided with a plurality of upper interlocking grooves 1111 at intervals, and the distance between two adjacent upper interlocking grooves 1111 is the same as the distance between the corresponding two adjacent longitudinal ribs 112 . The two adjacent longitudinal ribs 112 can be inserted into the two adjacent upper interlocking grooves 1111 .

[0048] In one embodim...

Embodiment 3

[0053] On the basis of any rib-skeleton concrete cast-in-place slab described in Embodiment 1 and Embodiment 2, this embodiment 3 provides a rib-skeleton concrete cast-in-situ slab with a connecting part 4, which is convenient for adjacent The connection between rib-frame concrete cast-in-place slabs or the connection between rib-frame concrete cast-in-place slabs and load-bearing beams. In one embodiment, see Figure 6 and Figure 7 As shown, a plurality of connecting parts 4 are arranged on the side of the rib-frame concrete cast-in-place slab, and after pouring concrete, at least a part of each connecting part 4 protrudes from the rib-plate skeleton concrete cast-in-place slab.

[0054] In some embodiments, the connection part 4 can be a structure such as a straight steel bar, a U-shaped steel bar, a straight-line plate or a U-shaped plate, and its uniform end is fixedly connected to the rib frame 1, and the other end protrudes from the rib frame to cast in-situ concrete. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com