Reusable electric explosion valve

A valve and electric explosion technology, applied in valve details, cocks including cut-off devices, engine components, etc., can solve problems such as poor performance of aerospace power plants, poor economy of aerospace power systems, failures, etc., to improve repeatability. The number of times of use, the wide range of applicable pressures, and the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

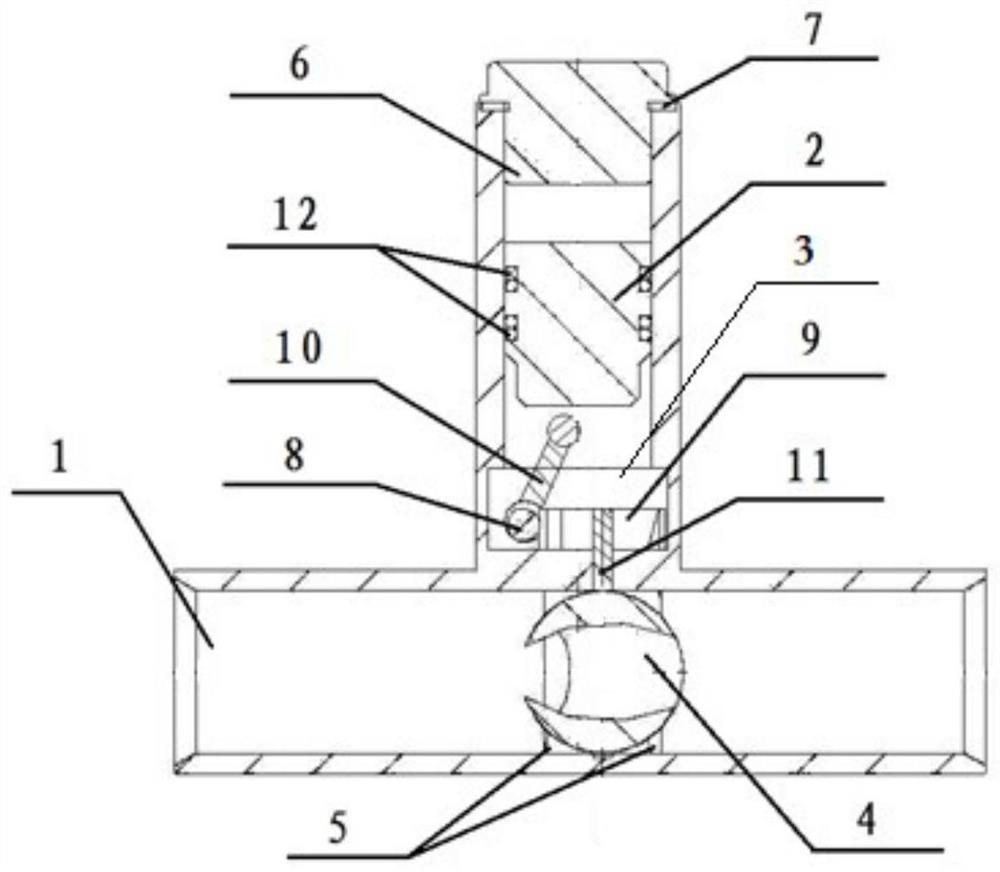

[0022] The reusable electric explosion valve will be further described below in conjunction with the accompanying drawings.

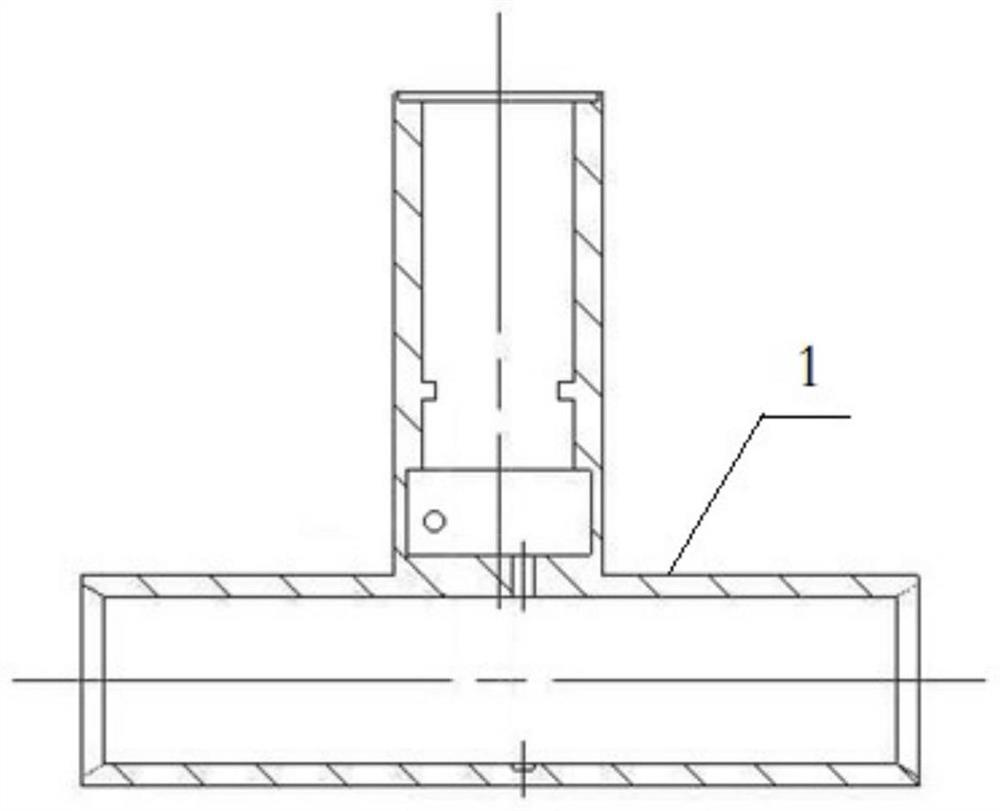

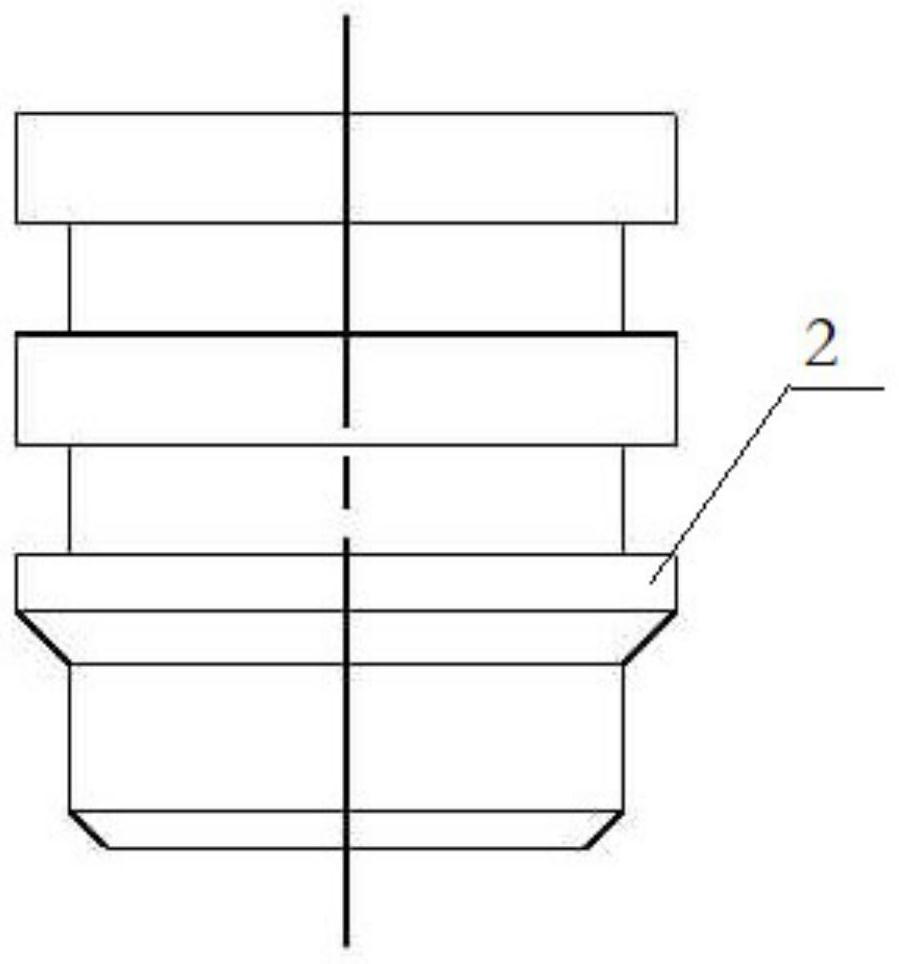

[0023] This reusable electric explosion valve, such as figure 1 , a reusable electric explosion valve, including: a housing 1, a piston 2, a transmission mechanism 3, a valve ball 4, a sealing rubber ring 5, an igniter 6, a gasket 7, and a rubber ring 12. The piston 2 is placed at the upper end of the casing 1, the front end of the piston 2 is connected with the transmission mechanism 3, the tail end of the piston 2 is connected with the igniter 6 through glue, and there is an apron 12 between the piston 2 and the casing 1, which is used to prevent the igniter 6 from igniting produced impurities. The igniter 6 is mounted on the upper end of the casing 1 and sealed by a gasket 7 . The transmission mechanism 3 is installed and fixed in the housing 1 , and the transmission mechanism 3 is connected with the valve ball 4 .

[0024] Such as Figure 4 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com