Preparation system of mine microorganism mineralized filling

A filling material and preparation system technology, applied in the preparation of test samples, etc., can solve the problems of low preparation efficiency, low test piece repeatability, large error, etc., achieve efficient preparation, enrich the theoretical basis, and eliminate experimental errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

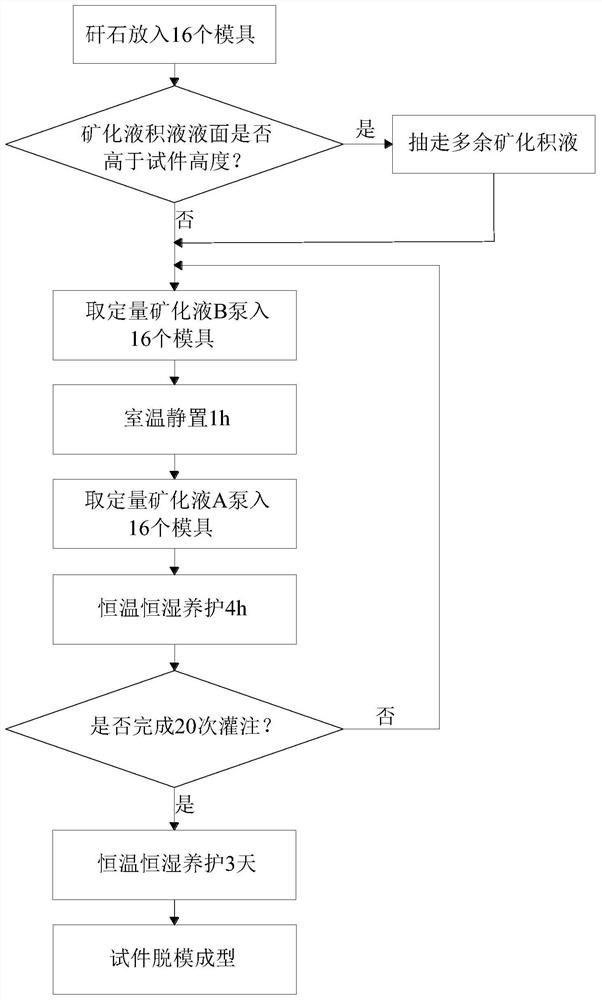

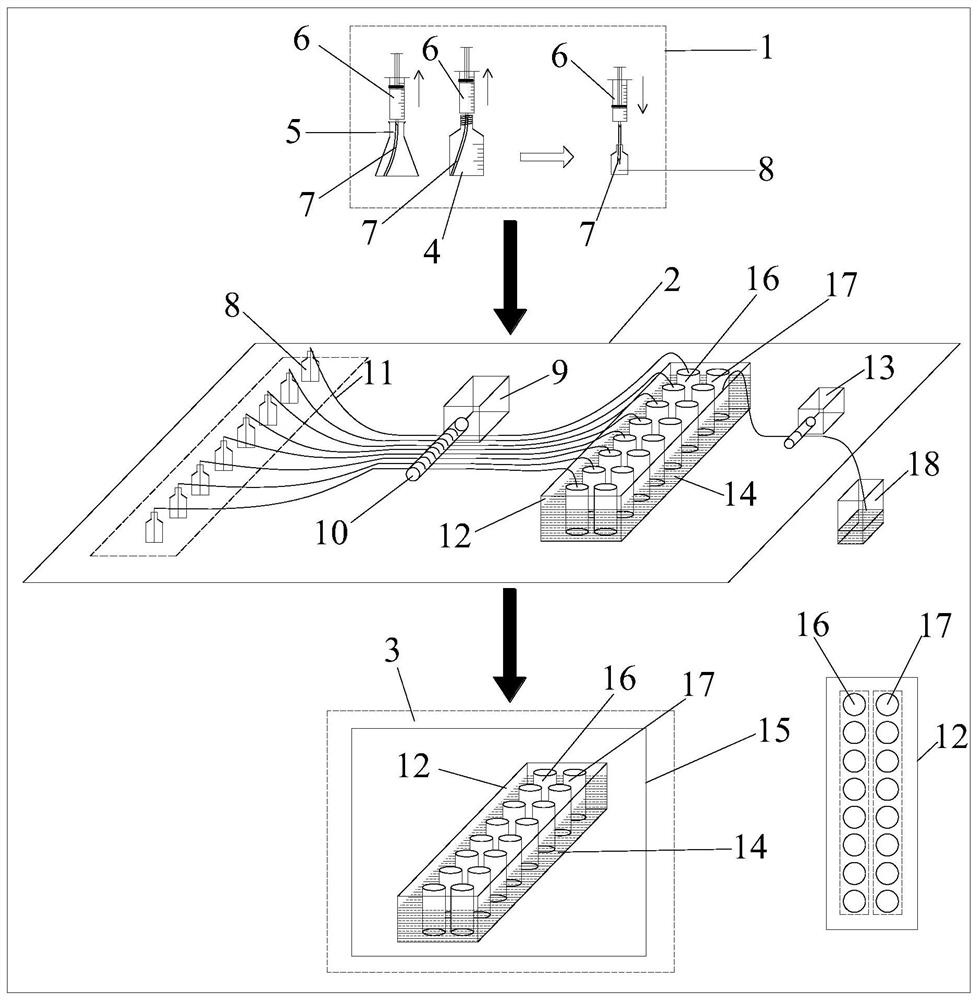

[0025] The present invention will be further described below in conjunction with the accompanying drawings. Taking the eight-channel-two-group test as an example, the following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0026] The preparation system for mine microbial mineralized filling materials includes three parts: manual liquid extraction-injection system 1, eight-channel mineralization liquid perfusion system 2, and material soaking-maintenance system 3.

[0027] The manual liquid extraction-injection system 1 and the eight-channel mineralization fluid perfusion system 2 are carried out in a fume hood.

[0028] The manual taking-injection system 1 is mainly composed of a 1L silk bottle 4, a 500ml Erlenmeyer bottle 5, a hand-held needleless syringe 6, a rubber hose 7, and a 50ml silk bottle 8. When performing manual extraction-injection, at first the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com