Automatic health inspection method and system for complex equipment based on intelligent scheduling

A technology of automatic inspection and intelligent scheduling, applied in transmission systems, instruments, electrical components, etc., to achieve the effect of fast and effective fault handling, rich functions, and loss avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

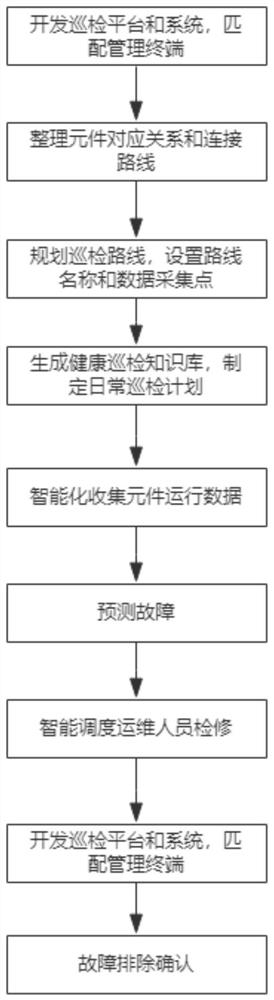

[0030] see figure 1 , a complex equipment health automatic inspection method and system based on intelligent scheduling, characterized in that: comprising the following steps;

[0031] S1. Use the Internet of Things technology to develop the "complex equipment health automatic inspection platform", and at the same time develop the complex equipment health automatic inspection system that matches the "complex equipment health automatic inspection platform", and equip it with the complex equipment health automatic inspection system Matching PC management terminal and mobile management terminal;

[0032] S2. Understand and analyze the equipment information of complex equipment that needs to be intelligently dispatched and managed, and sort out the correspondence and connection routes between the components of complex equipment;

[0033] S3. According to the corresponding relationship between the components of the complex equipment and the connection route, plan the inspection ro...

Embodiment 2

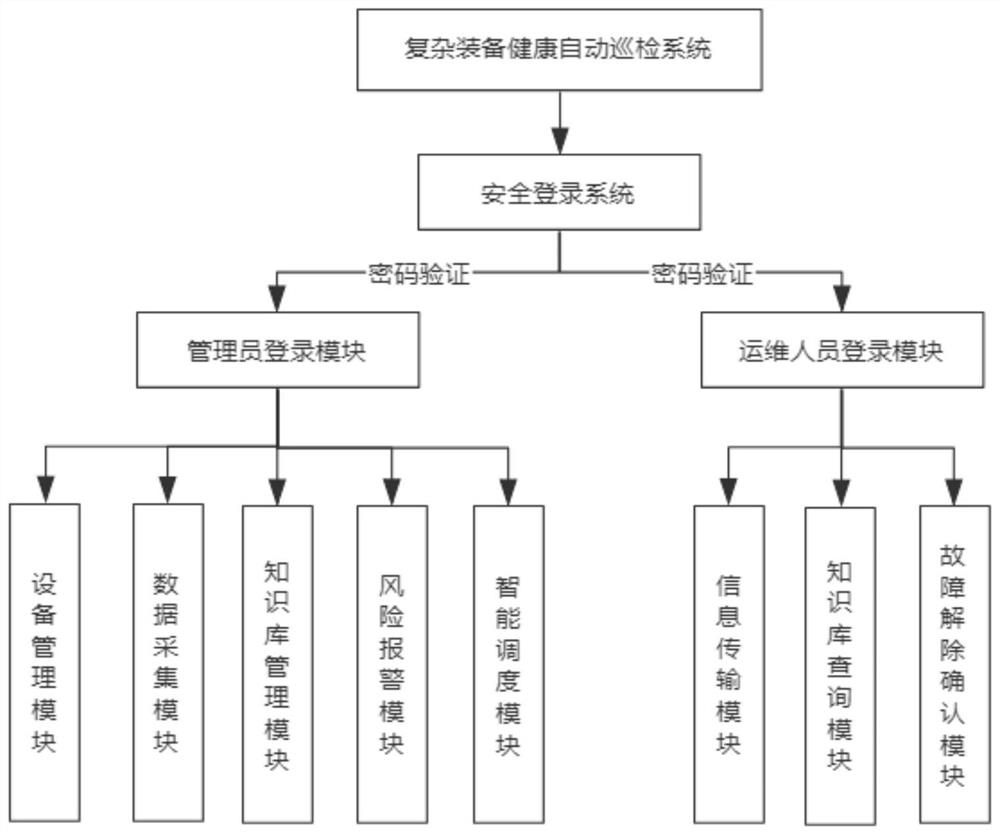

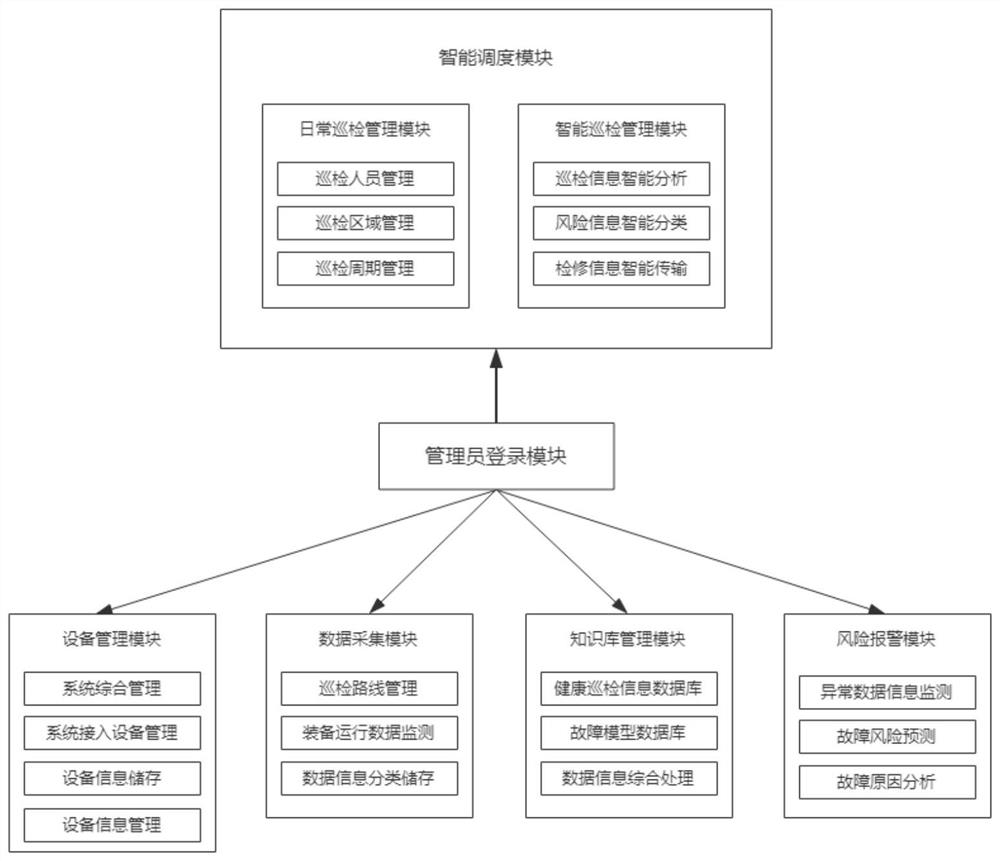

[0042] see Figure 2-3 , based on Example 1, but the difference is that the complex equipment health automatic inspection system mentioned in S1 matches the complex equipment health automatic inspection method based on intelligent scheduling, and the complex equipment health automatic inspection system includes Security login system, a password verification unit is linked to the security login system. The installation login system includes an administrator login module and an operation and maintenance personnel login module. The administrator login module includes a device management module, a data acquisition module, a knowledge base management module, a risk The alarm module, the intelligent scheduling module, and the operation and maintenance personnel login module are connected with an information transmission module, a knowledge base query module and a fault removal confirmation module.

[0043] The device management module is linked with a system comprehensive management...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com