Diamond anvil cell heating gasket and preparation method thereof

A diamond anvil and heating pad technology, applied in the direction of ohmic resistance heating, heating element materials, electric heating devices, etc., can solve the problems of large temperature gradient and difficult temperature measurement, achieve pressure stability, inhibit oxidation damage, avoid The effect of test error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A kind of diamond anvil heating gasket of the present invention, its structure and characteristics are as follows Figures 11 to 14 Shown: Metal rhenium sheet 7 is insulated from metal steel sheet I1 by mica sheet III6 and mica sheet IV8 in the middle of U-shaped metal steel sheet I1; metal rhenium sheet 7 is bent into U-shaped metal steel sheet I1 The U-shaped bend is filled with high-temperature-resistant insulating cement 10; the metal rhenium sheet 7 and the U-shaped metal steel sheet I1 are connected and conducted with the heating body metal platinum 11 in the heating body filling hole, and the heating body metal platinum Prepare the sample cavity 13 in 11; the metal rhenium sheet 7 and the metal steel sheet Ⅰ1 bent into a U shape are respectively drawn out by the metal copper wire 14; the indentation of the U-shaped metal steel sheet Ⅰ1 is pressed with di Aluminum insulation12.

[0050] combined with Figure 15 , 16 , the dimensions of each part in this embodim...

Embodiment 2

[0065] combined with Figure 1-12 The preparation process of the present invention is explained.

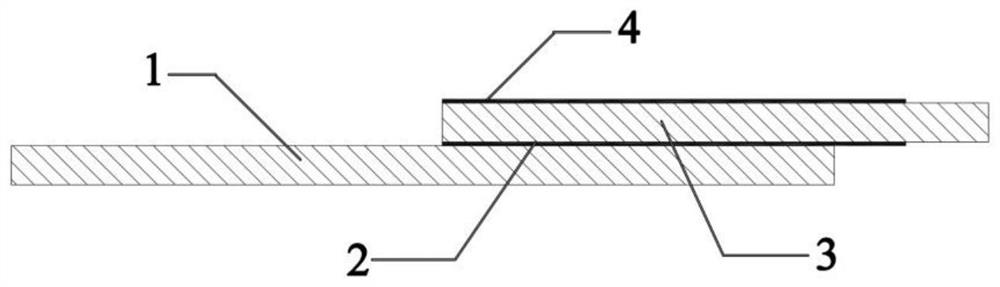

[0066] In the first step, the prepared mica sheet I2 is placed on the metal steel sheet I1, then the metal steel sheet II3 is placed on the mica sheet I2, and a layer of mica sheet II4 is placed on the metal steel sheet II3 again, such as figure 1 shown;

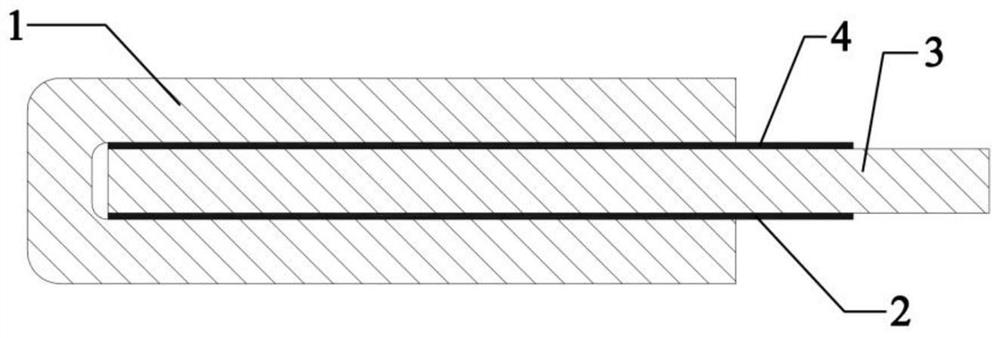

[0067] The second step: bend the metal steel sheet Ⅰ1 in the laminated body obtained in the first step to the stacked side, and make the metal steel sheet Ⅰ1, mica sheet Ⅰ2, mica sheet Ⅱ4 and metal steel sheet Ⅱ3 in the laminated body tightly fit, such as figure 2 shown;

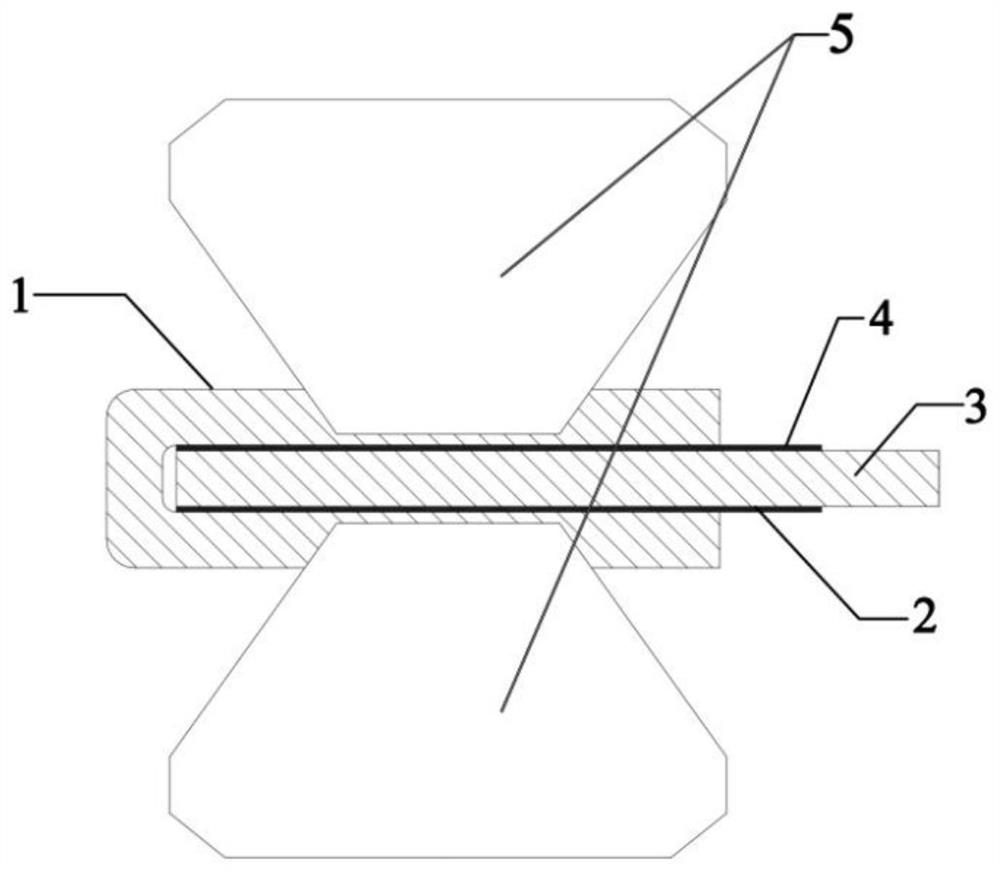

[0068] Step 3: If image 3 As shown, the laminated body obtained in the second step is placed on a diamond with a diameter of 0.5 mm anvil surface to carry out indentation pre-compression in the middle of the anvil 5, and the obtained laminated body with indentation wraps mica sheet I2, mica sheet II4 and metal The structure of steel sheet Ⅱ3, such as ...

Embodiment 3

[0077] A DC power supply is used to supply and heat a diamond anvil heating pad of the present invention. On the maximum output gear of the DC power supply used, under the conditions of a voltage of 3V and a current of 9.5A, the inside of the pressure chamber can achieve a stable temperature of up to 1620K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com