Scald instrument and using method

An instrument and digital technology, applied in the field of scald instrument, can solve the problems of poor consistency and repeatability, inability to accurately manufacture scald models, etc., achieve good accuracy, and solve the effect of rapid and uncontrolled temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A scald instrument and a method for manufacturing burn wounds:

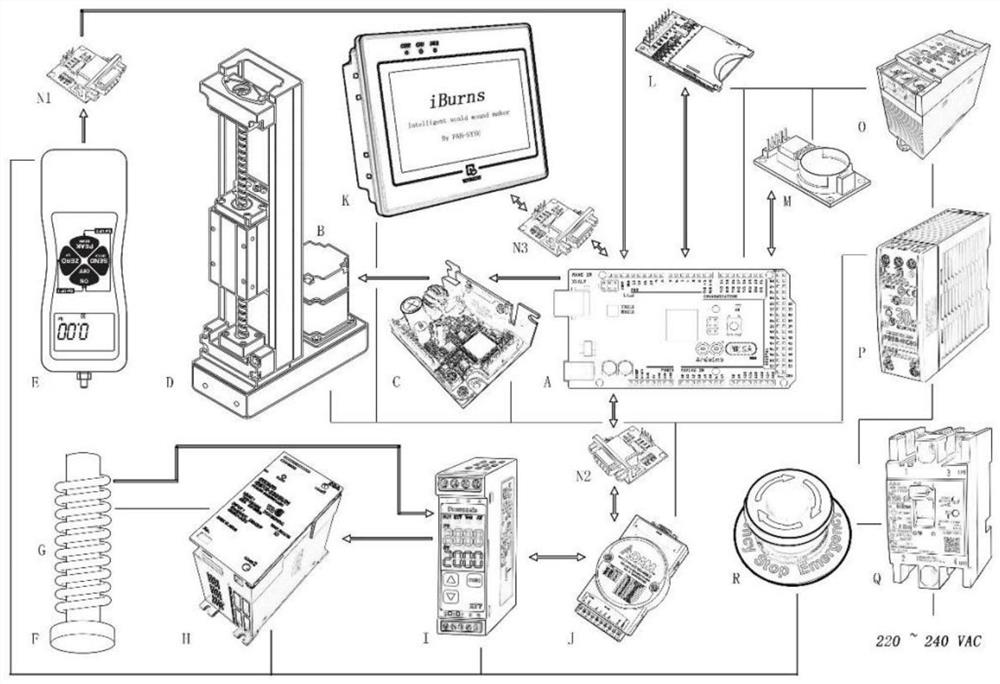

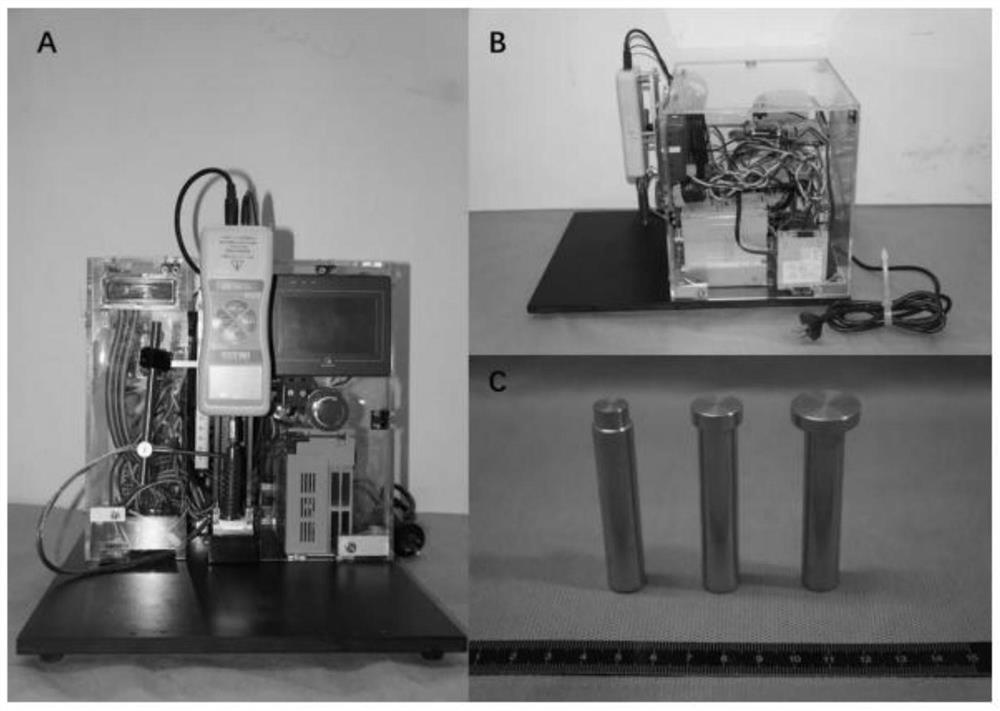

[0043] As attached figure 1 As mentioned, the entire automatic scald instrument is built with Arduino Mega2560 as the control center, including:

[0044] The human-computer interaction interface composed of Weinview MT6050i touch screen is used to input information, set parameters, display operation and detection information;

[0045] The actuator is composed of Oriental Motor Vexta BLHM015K-50 stepper motor and its driver, and IKO TU40C26A Z-axis precision positioning table (electric cylinder), which is used to control the rising and falling of the heating head and adjust the heating head applied to the animal Pressure

[0046] Pressure detection system composed of IMADA DS2-200N dynamometer;

[0047] Heating and temperature monitoring and control system, by OMRONG3PX-220EUN Power Controller single-phase power regulator, NAiS KT7 digital thermostat, 300W rated power hot runner with thermocouple heating tube and cu...

Embodiment 2

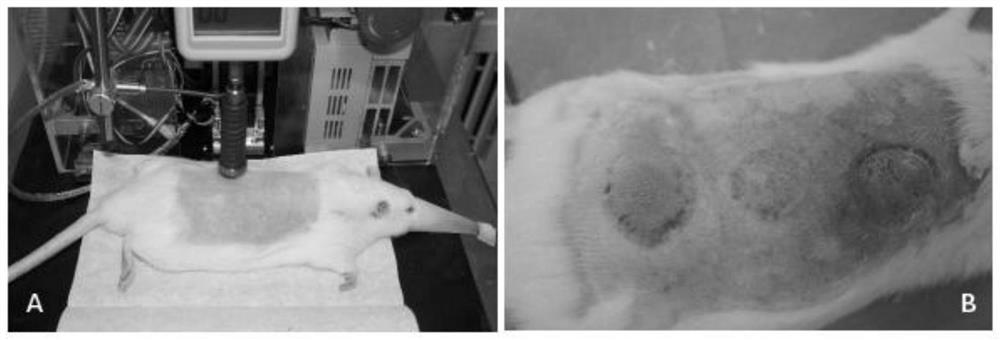

[0056] Example 2 is an animal experiment on the scald wound made by the apparatus of Example 1:

[0057] (1) Animal handling and modeling steps

[0058] As attached image 3 As shown, 6-week-old SPF male SD rats (220-240g) were selected for the experiment, provided by the Experimental Animal Center of Sun Yat-sen University. In the first part, 27 rats were included. According to the results of the preliminary experiment, 3 different burn temperature groups were set: 60℃, 80℃, 100℃ (the number of animals included in each group was n=9), and each temperature group was divided into 3 Pressure value group: 0.6N, 0.8N, 1.0N (the number of animals included in each pressure value n=3), the animals were randomly assigned. The burn time is uniformly set to 10s, and the diameter of the ironing head is uniformly 20mm. In the second part, two additional animals under 60℃, 0.6N, 10s conditions and two under 80℃, 0.8N, 10s conditions were added to test the consistency of shallow scald modeling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com