Rehmannia glutinosa polysaccharide/xenogeneic calcined allo-bone composite bone repair material

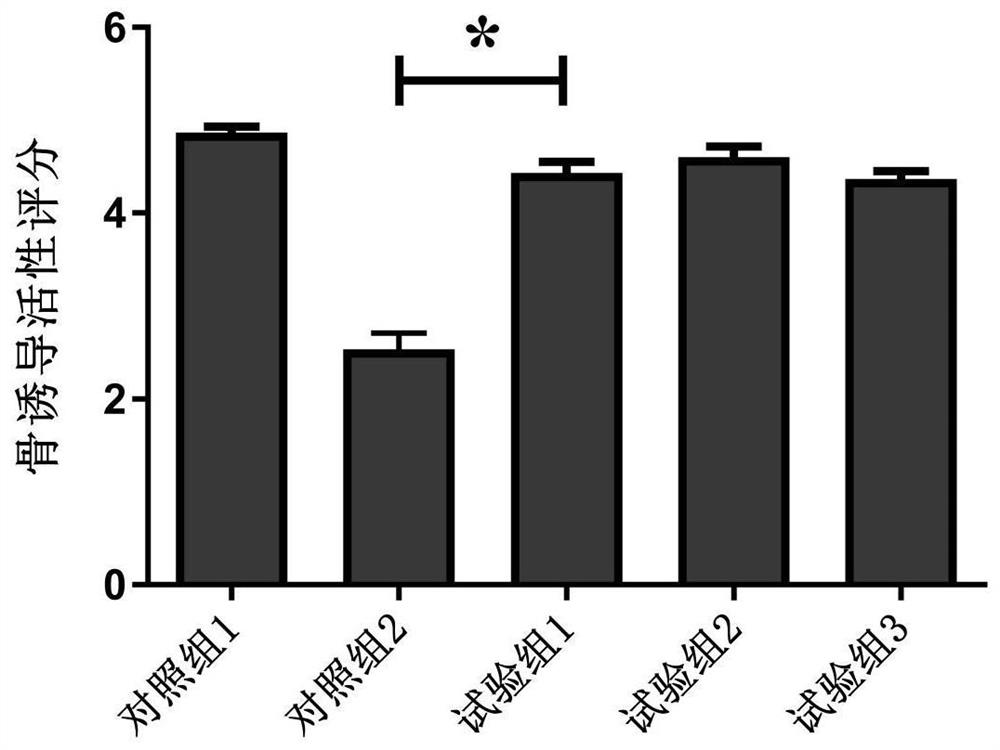

A technology of rehmannia polysaccharide and calcined bone, which is applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of insufficient osteoinductive activity, achieve excellent osteogenesis effect, key technology control, and promote bone formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

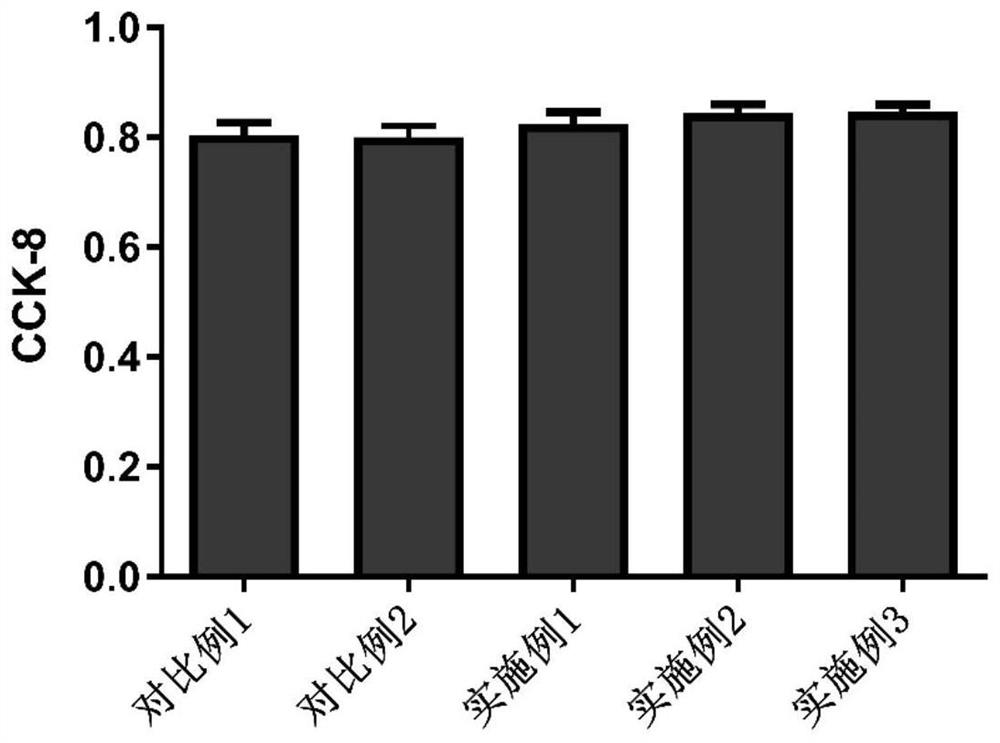

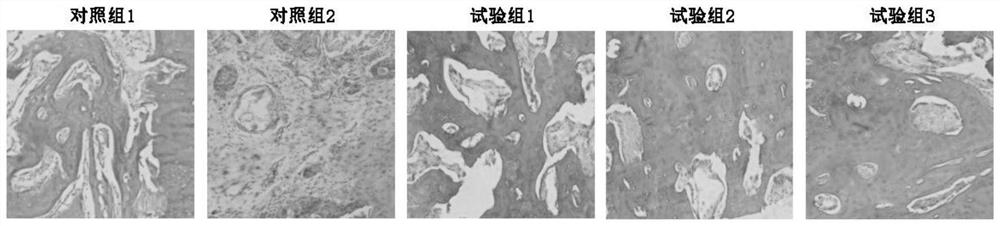

Examples

Embodiment 1

[0028] The rehmannia polysaccharide / heterogeneous calcined bone composite bone repair material of this embodiment:

[0029] 1. Preparation of heterogeneous calcined bone scaffold materials

[0030] The bilateral femurs of adult cattle were taken, and the cancellous bone part of the femoral epiphysis was sawed off, and other tissues attached to the bone were peeled off, and then cut into 4×4×4mm bone pieces with a cutting machine and washed; the washed The final bone was soaked in 0.5mol / L NaOH solution for 1 h, ultrasonically cleaned with purified water for 3 times, each time for 8 min, and then the bone was immersed in 3% H 2 o 2 Solution for 20 minutes, ultrasonic cleaning with purified water for 3 times, each time for 8 minutes; put the treated bone into boiling water, boil for 1 hour to remove part of the protein and lipid, dry the bone overnight after cooling, put the dried bone Put it into a muffle furnace for calcination, control the temperature and slowly raise the t...

Embodiment 2

[0038] The rehmannia polysaccharide / heterogeneous calcined bone composite bone repair material of this embodiment:

[0039] 1. Preparation of heterogeneous calcined bone scaffold materials

[0040] The bilateral femurs of adult cattle were taken, and the cancellous bone part of the epiphysis of the femur was sawed off, and other tissues attached to the bone were peeled off, and then cut into 5×5×5mm bone pieces with a cutting machine and washed; the washed The final bone was soaked in 0.5mol / L NaOH solution for 3h, ultrasonically cleaned with purified water for 3 times, each time for 10min, and then the bone was immersed in 3% H 2 o 2 Solution for 25 minutes, ultrasonic cleaning with purified water for 3 times, each time for 10 minutes; put the treated bone into boiling water, boil for 1.5 hours to remove part of the protein and lipid, after the bone is cooled, dry overnight, and dry the bone Put it into a muffle furnace for calcination, control the temperature and slowly in...

Embodiment 3

[0048] The rehmannia polysaccharide / heterogeneous calcined bone composite bone repair material of this embodiment:

[0049] 1. Preparation of heterogeneous calcined bone scaffold materials

[0050] The bilateral femurs of adult cattle were taken, and the cancellous bone part of the femoral epiphysis was sawed off, and other tissues attached to the bone were peeled off, and then cut into 6×6×6mm bone pieces with a cutting machine and washed; the washed The final bone block was soaked in 0.5mol / L NaOH solution for 3h, ultrasonically cleaned with purified water for 3 times, each time for 15min, and then the bone block was immersed in 3% H 2 o 2 solution for 45 minutes, ultrasonically cleaned with purified water for 3 times, each time for 15 minutes; put the treated bone into boiling water, boil for 2 hours to remove part of the protein and lipid, dry the bone overnight after cooling, put the dried bone in Put it into a muffle furnace for calcination, control the temperature and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com