Multifunctional bionic HA particles loaded curcumin prodrug micro-nano composite material, preparation method and application thereof

A multifunctional, composite material technology, applied in chemical instruments and methods, pharmaceutical science, phosphorus compounds, etc., can solve the problem of drug loading rate of only about 2-3%, and achieve enhanced anti-cancer effect, growth inhibition, excellent Bone-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation of curcumin nanometer prodrug comprises the steps:

[0045] (1) mPEG-modified SA with a molecular weight of 550: Weigh 8 g of mPEG 550 , 1.6 g of succinic anhydride, and 0.56 g of p-toluenesulfonic acid were placed in a flask, under nitrogen environment protection, and reacted at 80° C. for 3 h. The finished product was dissolved in 30ml of dichloromethane, filtered to get the filtrate, and then recrystallized repeatedly with 160mL of anhydrous ether at -5°C, freeze-dried to obtain the mPEG product modified with SA (mPEG 550 -SA);

[0046] (2) mPEG 550 -SA modified curcumin: take the mPEG product (mPEG) modified with SA described in step (1). 350 -SA) 2.7g, curcumin (0.54g), N,N'-dicyclohexylcarbodiimide (1.4g), 4-dimethylaminopyridine (0.1g), triethylamine (0.1mL) In an ultra-dry dichloromethane solution (50ml), under a nitrogen protection environment for 12h, filter the reacted solution to remove the precipitate, then mix the filtrate with 250mL an...

Embodiment 2

[0048] The preparation of composite micro-nano particles comprises the following steps:

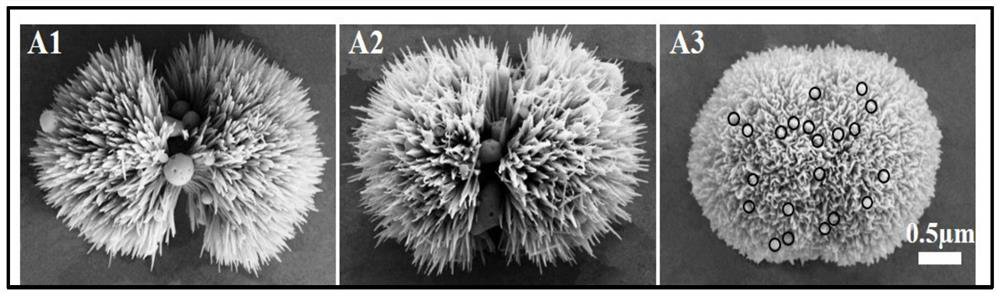

[0049] (1) Preparation of hydroxyapatite powder with hierarchical structure: 4 mM diammonium hydrogen phosphate was prepared, and the pH was adjusted to 6 to obtain solution a. Add calcium nitrate to solution a, the molar volume ratio of calcium nitrate to solution a is 6.6:1 mmol / L, stir well to obtain solution b. Then 1 mmol sodium citrate was added to solution b and stirred vigorously, and the mixture was transferred to a polytetrafluoroethylene-lined autoclave, and reacted at 180 °C for 3 h. The resulting precipitate was centrifuged and freeze-dried to prepare HA particles. The HA particles have a relatively high hollow structure with a specific surface area of up to 64.8m 2 / g.

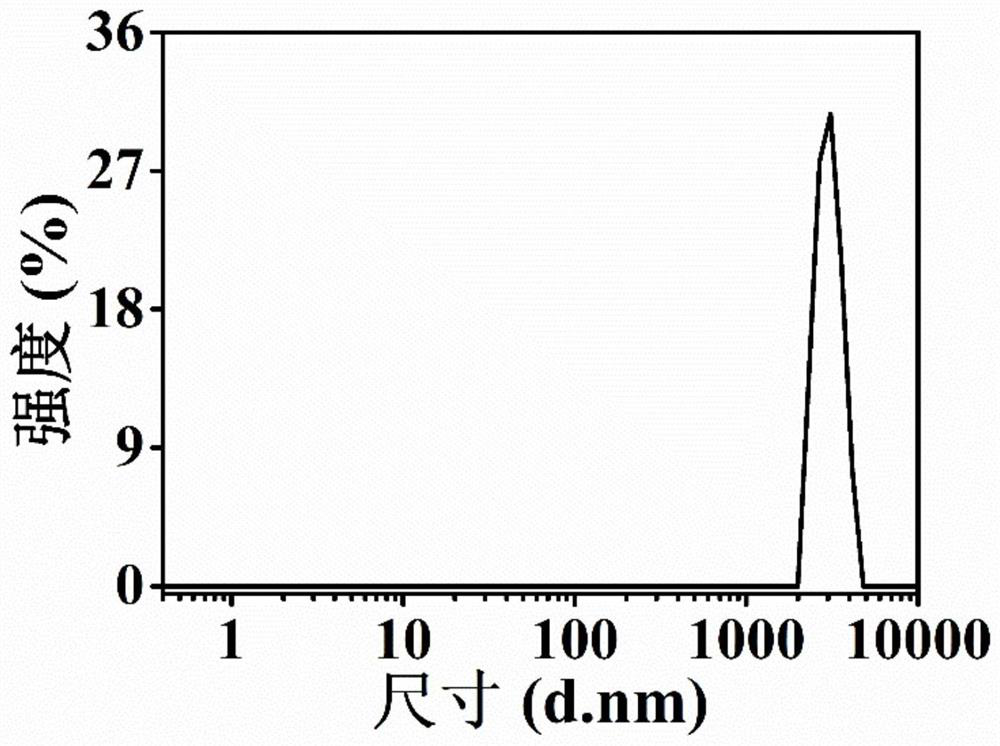

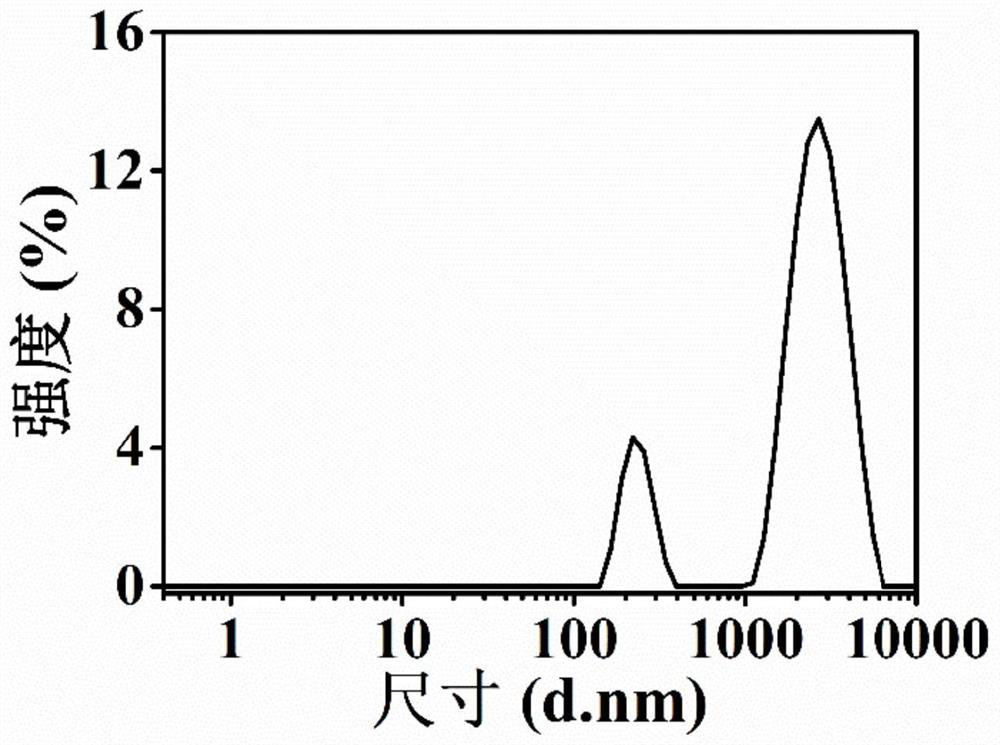

[0050] (2) Preparation of HA particle-loaded curcumin prodrug composite micro-nanoparticles: Weigh 20mg HA particles and 20mg grafted with mPEG prepared in Example 1 550 -The curcumin prodrug of SA was...

Embodiment 3

[0052] The preparation of composite micro-nano particles comprises the following steps:

[0053] (1) Preparation of biomimetic HA micro-nanoparticles: 6.0 mM diammonium hydrogen phosphate was prepared, and the pH was adjusted to 6 to obtain solution a. Add calcium nitrate to solution a, the molar volume ratio of calcium nitrate to solution a is 10:1mmol / L, stir well to obtain solution b. Then 1.5 mmol of sodium citrate was added to solution b and stirred vigorously, and the mixture was transferred to a polytetrafluoroethylene-lined autoclave, and reacted at 180 °C for 3 h. The resulting precipitate was centrifuged and freeze-dried to prepare HA particles. The HA particles have a relatively high hollow structure with a specific surface area of up to 74.8m 2 / g.

[0054] (2) Preparation of HA particle-loaded curcumin prodrug composite micro-nanoparticles: Weigh 20mg HA particles and 20mg grafted with mPEG prepared in Example 1 550 -The curcumin prodrug of SA was dissolved ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com