Sludge distribution filter pressing device

The technology of filter press plate and filter press is applied in the fields of filtration and separation, sludge treatment, water/sludge/sewage treatment, etc., which can solve the problems of low mud cake speed, large floor space and small processing capacity, etc. Achieve the effect of high mud removal efficiency and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

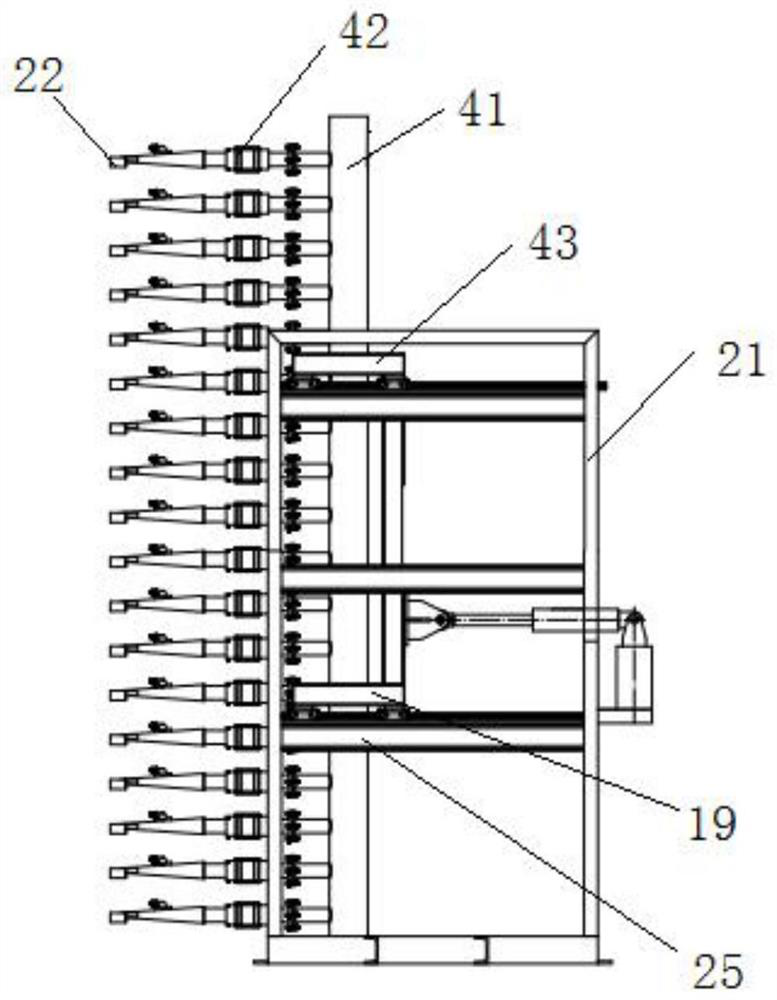

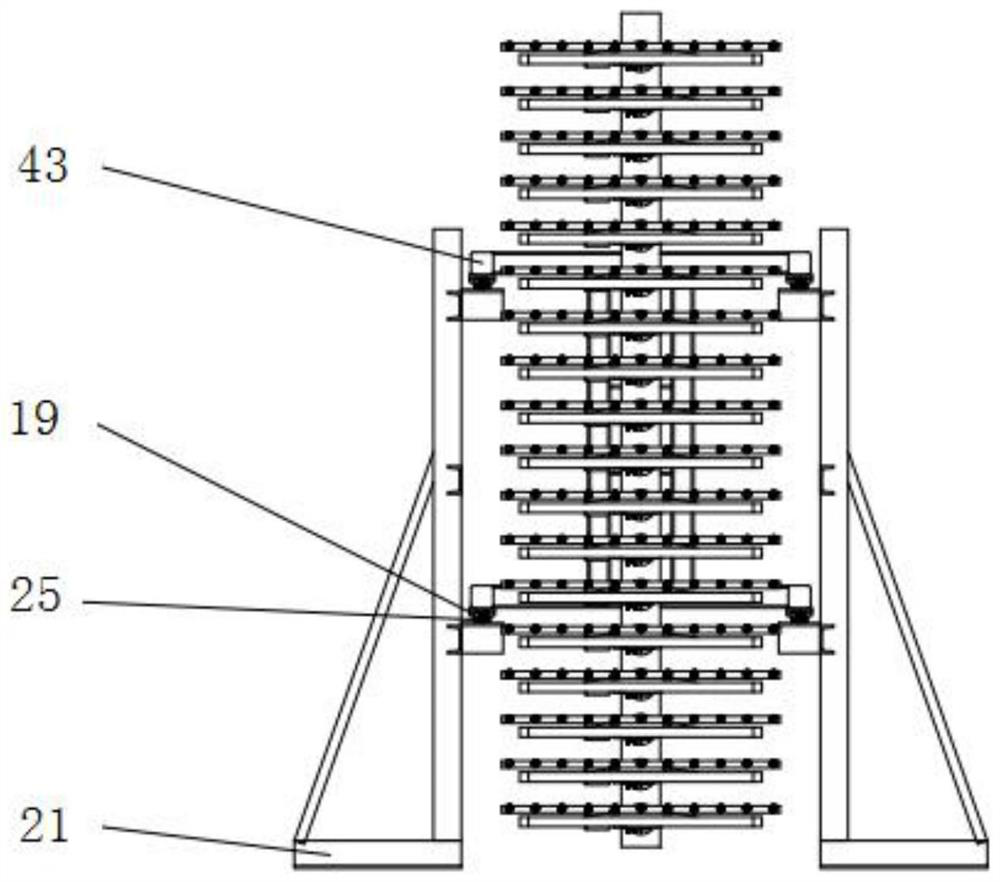

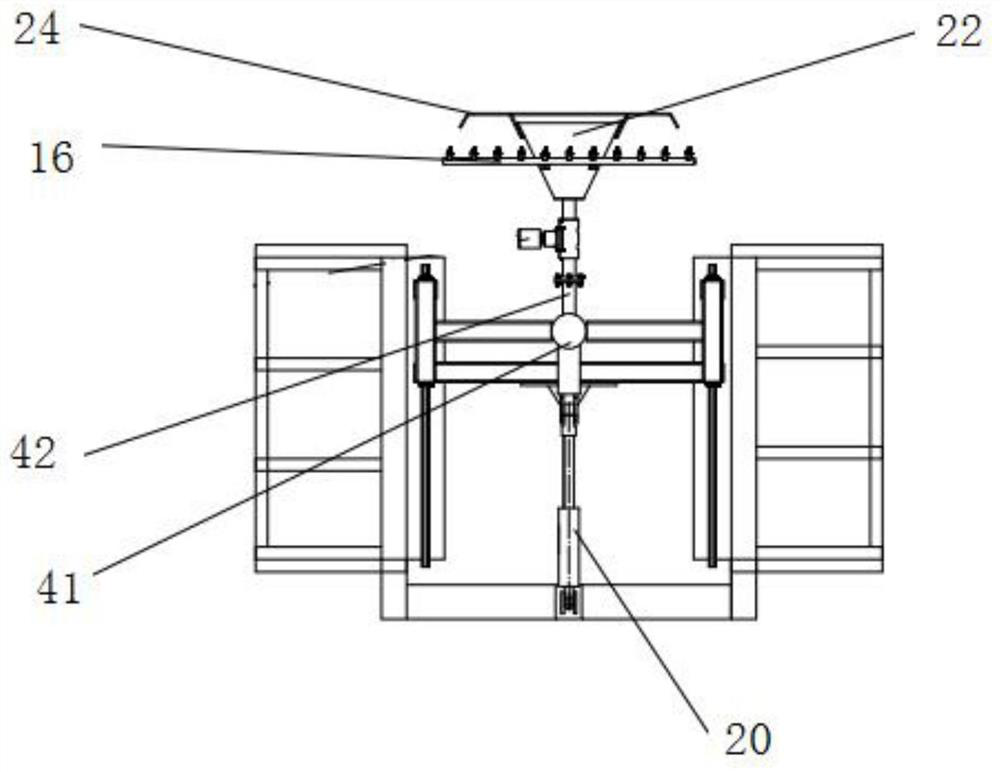

[0061] One, the present invention provides a kind of cloth mud press filter device, such as Figure 4-5As shown, it includes a mud distribution machine and a filter press set beside its mud distribution nozzle 22, including a filter press assembly, a lifting mechanism and a press 1. The filter press and the mud distribution machine are two pieces of equipment that work together. When each filter plate 15 of the filter press is opened, the mud distribution nozzle 22 advances horizontally between each filter plate 15 to start the mud distribution; When the machine is about to start the filter press action, the mud distribution nozzle 22 retreats horizontally to stop the mud distribution, and the filter press plates 15 are combined to filter the materials distributed between the filter press plates 15 . The materials to be treated can be sewage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com