Full-automatic solid-liquid separation system suitable for sludge treatment

A sewage treatment system and solid-liquid separation technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. High labor costs and other issues, to achieve the effect of reduced floor area and high mud output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

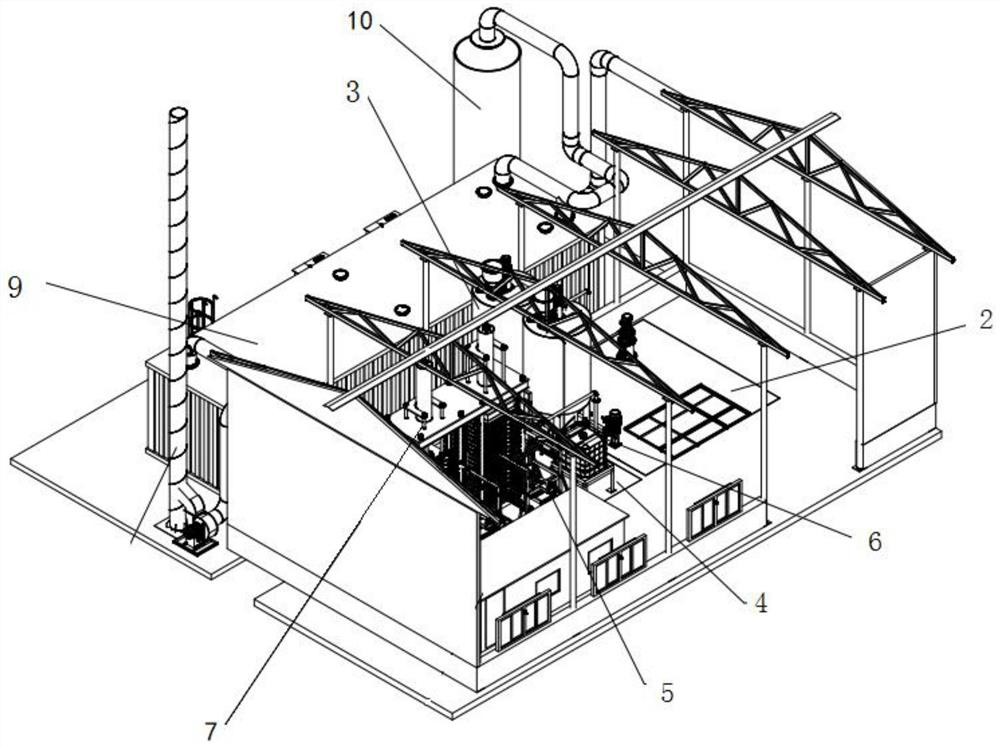

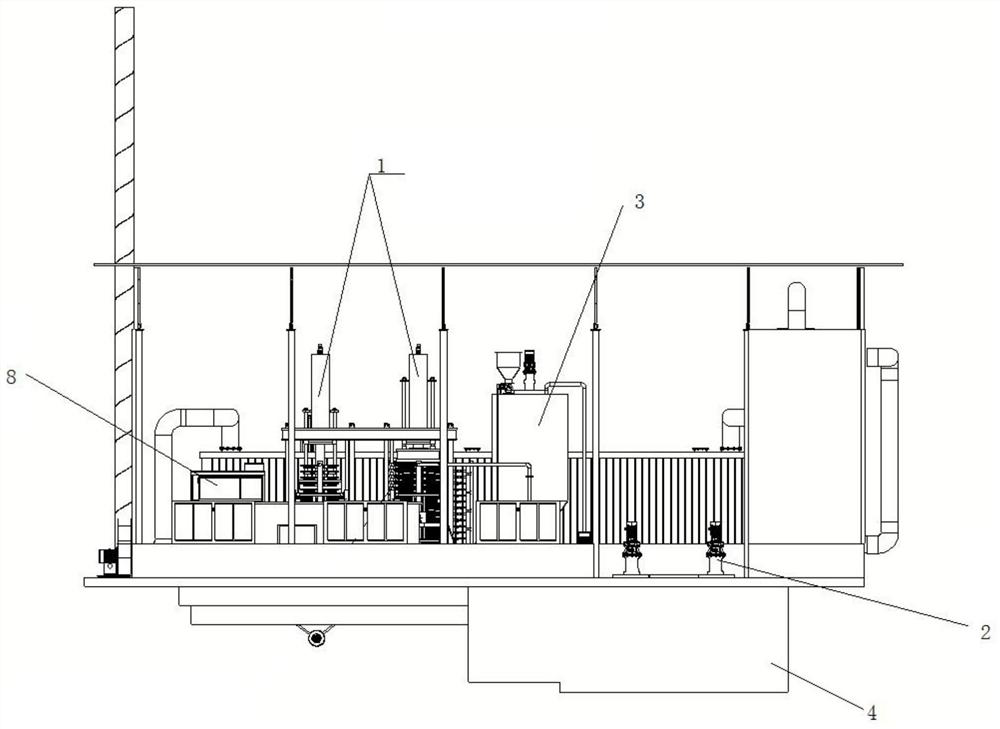

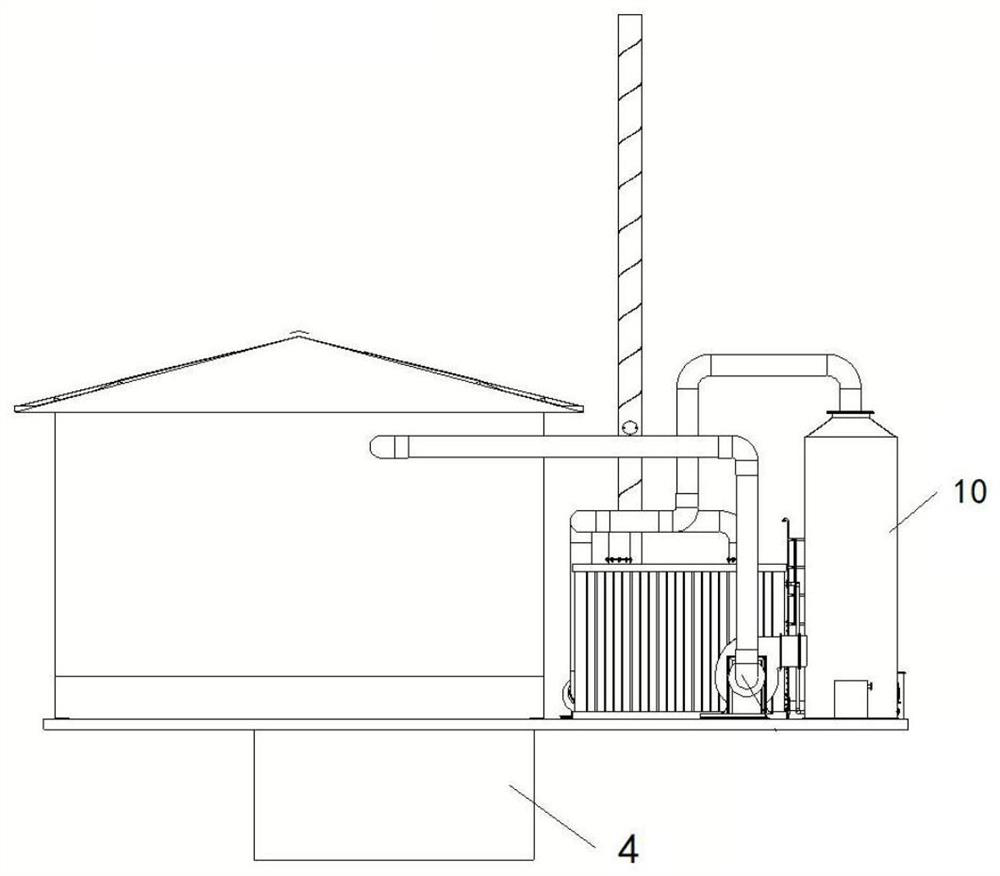

[0071] 1. The present invention provides a fully automatic solid-liquid separation system suitable for sludge treatment, such as Figure 1-3 As shown, it includes a material pretreatment system, a mud distributor 5 and a filter press 7; it may also include a mud cake collection system, a sewage treatment system and / or an air suction and biological deodorization device 9.

[0072] 1. The material pretreatment system includes a sludge mixing bin 2 and a conditioning tank 3, and may also include an automatic conditioning agent feeding device 6. Among them, the sludge mixing bin 2 is used to receive the materials to be processed. The source of the materials to be processed can be transported to the sludge mixing bin 2 by a solid-liquid transport vehicle, or directly at the site where various types of sludge need to be processed. The built-in pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com