A metal layered composite plate pass rolling forming method

A technology of pass rolling and clad plate, which is applied in the field of metal layered clad plate preparation, can solve the problems of low shear bond strength, uncoordinated rolling extension, aluminum overflow, etc., so as to improve the interface bond strength and reduce the impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

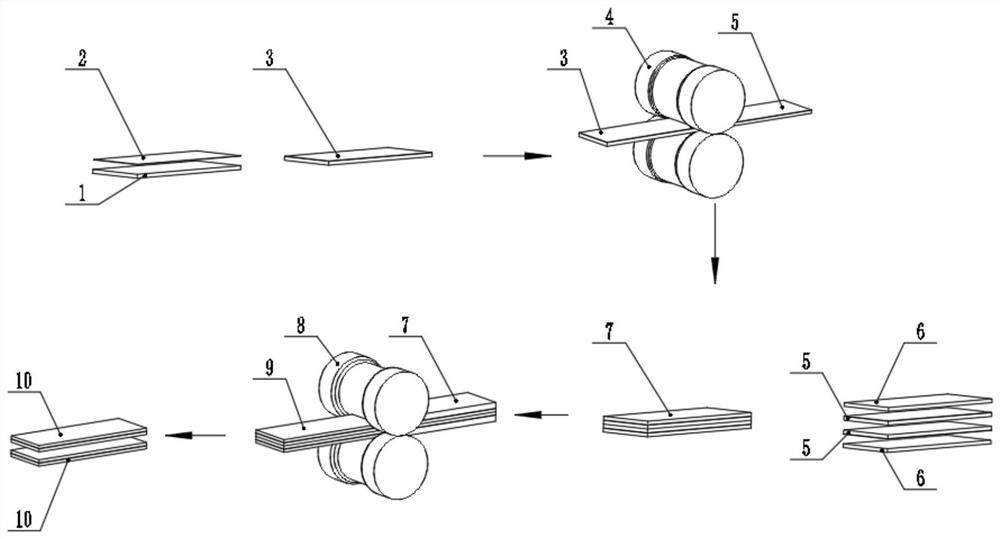

[0032] refer to figure 1 As shown, this embodiment provides a metal layered composite plate pass rolling forming method for preparing Q235 / 1060 / 3003 layered composite plate, specifically including:

[0033] S1. Prepare the steel plate 1 to be clad and the aluminum plate 2 to be clad and perform surface treatment:

[0034]Prepare a piece of steel plate 1 to be clad with a length x width x height of 3000 x 400 x 10mm and a material of Q235, anneal the steel plate 1 to be clad at 600° C. for 2 hours and then air cool it to remove the oil and dirt on the surface to be clad in the steel plate 1 to be clad. Oxide film, clean the surface to be compounded of the steel plate 1 to be compounded with acetone and alcohol, and then use a grinder to polish the surface to be compounded of the steel plate 1 to be compounded. × Width × height is 3000 × 400 × 0.2mm, the industrial pure aluminum plate of material is 1060 is used as the aluminum plate 2 to be compounded, the aluminum plate 2 to ...

Embodiment 2

[0044] refer to figure 1 As shown, this embodiment provides a metal layered composite plate pass rolling forming method for preparing Q235B / 1050 / 5083 layered composite plate, specifically including:

[0045] S1. Prepare the steel plate 1 to be clad and the aluminum plate 2 to be clad and perform surface treatment:

[0046] Prepare a piece of steel plate 1 to be clad with a length x width x height of 6000 x 500 x 40 mm and a material of Q235B, anneal the steel plate 1 to be clad at 600° C. for 2 hours, and then air cool it to remove oil and dirt on the surface to be clad in the steel plate 1 to be clad. Oxide film, clean the surface to be compounded of the steel plate 1 to be compounded with acetone and alcohol, and then use a grinder to polish the surface to be compounded of the steel plate 1 to be compounded. × Width × height is 6000 × 500 × 2mm, the industrial pure aluminum plate of material is 1050 is used as the aluminum plate 2 to be compounded, the aluminum plate 2 to b...

Embodiment 3

[0056] refer to figure 1 As shown, this embodiment provides a metal layered composite plate pass rolling forming method for preparing 304 / 1060 / 6061 layered composite plate, specifically including:

[0057] S1. Prepare the steel plate 1 to be clad and the aluminum plate 2 to be clad and perform surface treatment:

[0058] Prepare a piece of steel plate 1 to be clad with a length×width×height of 12000×100×20mm and made of 304 stainless steel, anneal the steel plate 1 to be clad at 600°C for 2 hours, and then air-cool it to remove oil stains on the surface to be clad in the steel plate 1 to be clad and oxide film, clean the surface to be compounded of the steel plate 1 to be compounded with acetone and alcohol, and then use a grinder to polish the surface to be compounded of the steel plate 1 to be compounded. The length × width × height is 12000 × 100 × 1mm, and the industrial pure aluminum plate with a material of 1060 is used as the aluminum plate 2 to be compounded. The alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com