Cold correction method for thin-wall steel member

A correction method and technology for steel components, applied in the field of steel structure construction, can solve problems such as inability to correct, heavy workload, and inability to guarantee quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further illustrated below by specific examples.

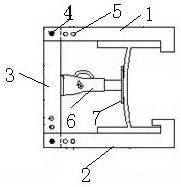

[0020] Such as figure 1 As shown, a cold correction method for thin-walled steel members, including

[0021] Step 1, making supporting tooling; including upper cross bar 1, lower cross bar 2, bottom bar 3, bolt 4, bolt hole 5, jack 6 and top plate 7;

[0022] in,

[0023] Both the upper cross bar 1 and the lower cross bar 2 are barb-shaped and are stuck on the component to prevent the lower flange of the component from moving upward when a force is applied to the component;

[0024] Bolt holes 5 are provided on the shafts of the upper cross bar 1 and the lower cross bar 2, and the bottom bar 3 is arranged between the upper cross bar 1 and the lower cross bar 2, and the bottom bar 3 is formed by inserting bolts 4 in different bolt holes 5. Make the opening between the upper crossbar 1 and the lower crossbar 2 adaptable to the width of different steel sections;

[0025] Step 2, erecting the jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com