Rotor turning machine

A turning and rotor technology, applied in the field of rotors, can solve the problems of low production efficiency and low turning precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

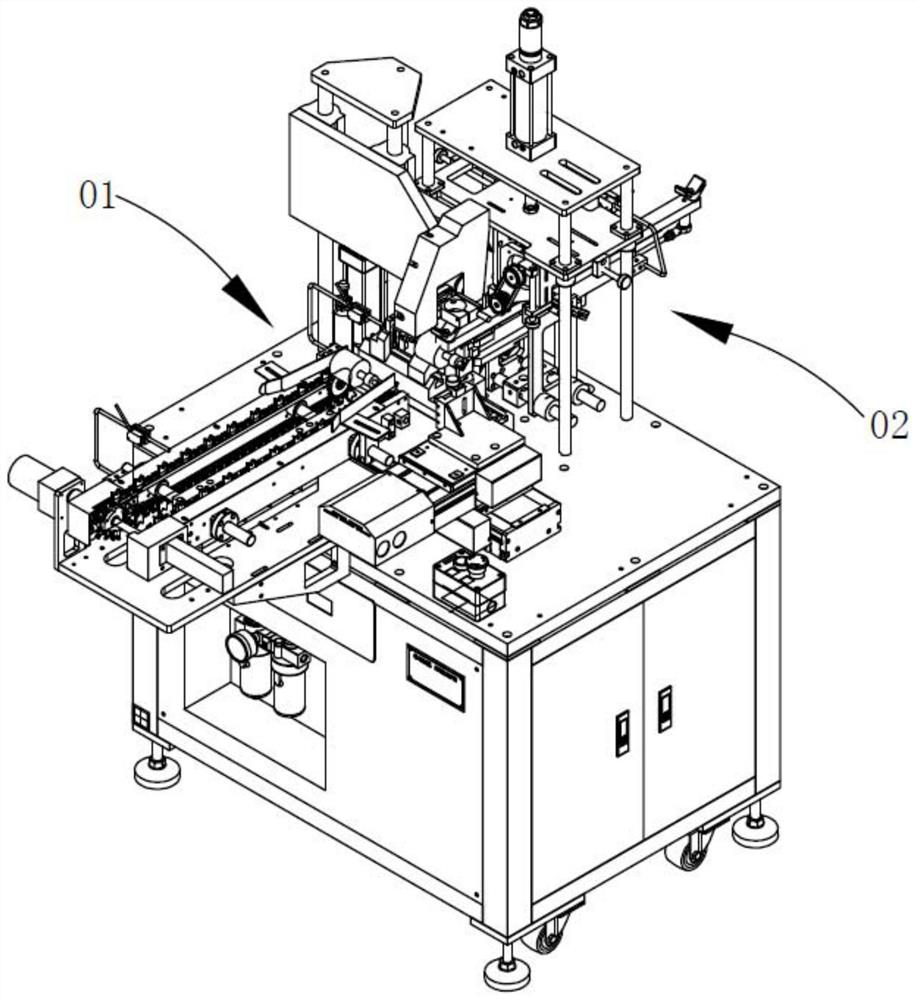

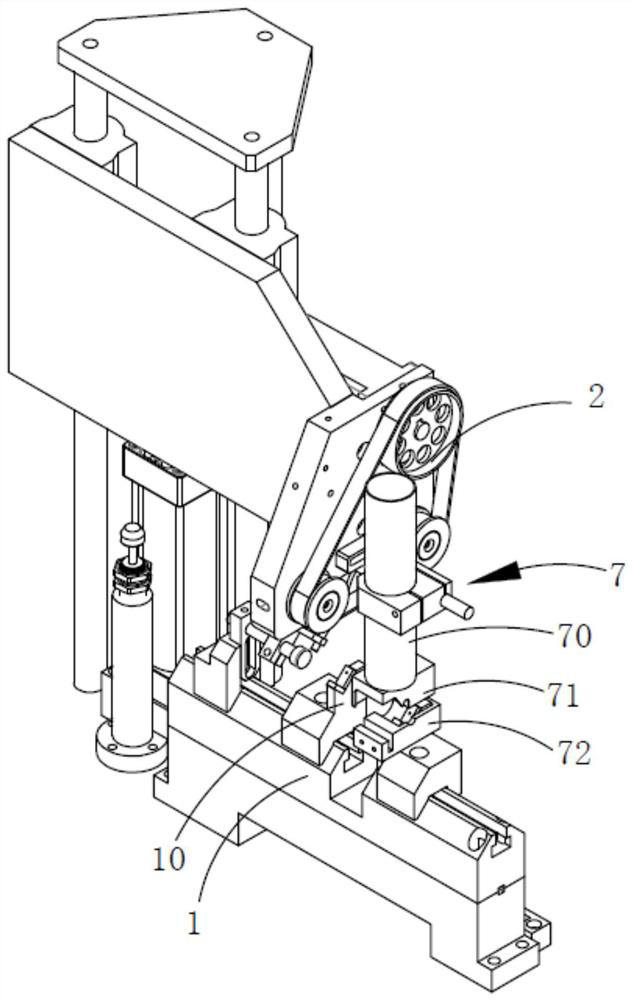

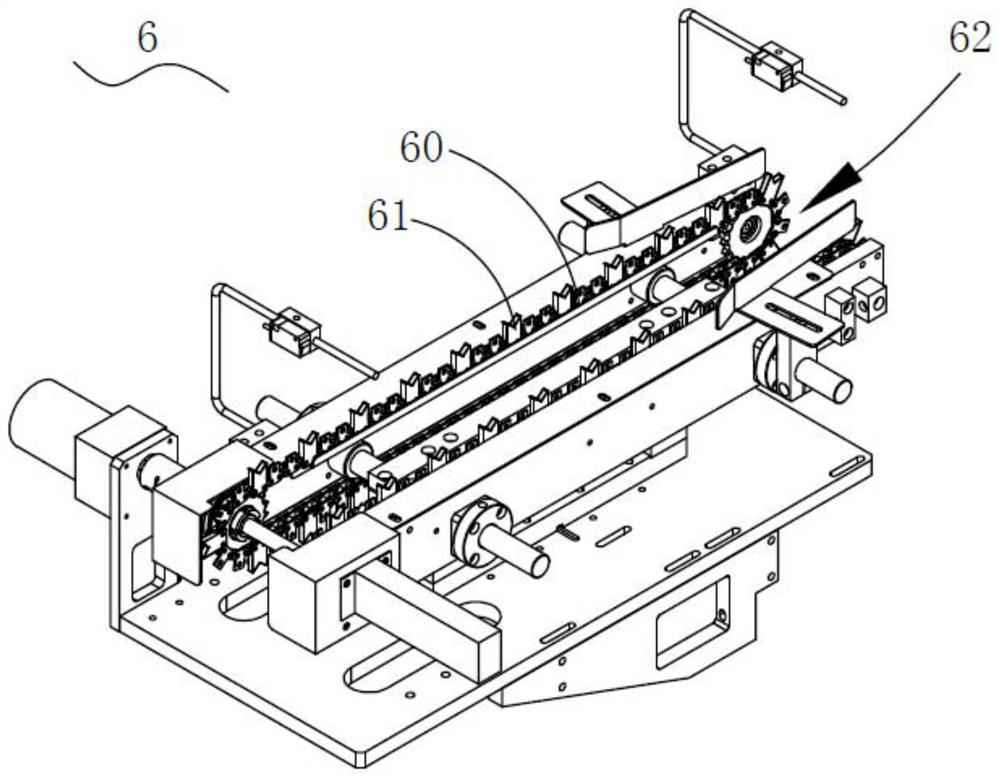

[0021] Such as Figures 1 to 6 As shown, a rotor turning machine provided by the present invention includes a turning station 01 and a copper sand cleaning station 02. The turning station 01 is provided with a turning seat 1 for carrying the rotor, and a first Pressing arm pulley mechanism 2 and turning tool module 3 for turning the rotor surface, copper sand cleaning station 02 is provided with copper sand cleaning mechanism 4, and between turning station 01 and copper sand cleaning station 02 is provided with reciprocating material transfer Mechanism 5 is used to transfer the rotor in the turning station 01 to the copper sand cleaning station 02. The first pressing arm pulley mechanism 2 is provided with a pressing arm, a pulley mechanism installed on the front end of the pressing arm and a mechanism for driving the pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com