Thimble type chip removing device and method for corrugated paper die cutting units

A thimble-type, corrugated paper technology, used in transportation and packaging, metal processing, sending objects, etc., can solve the problems affecting the normal progress of the corrugated cardboard die-cutting process, uneven width of the gap, affecting the quality of die-cutting, etc., to ensure normal Efficient operation, flexible and convenient use, quick and timely removal of paper scraps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

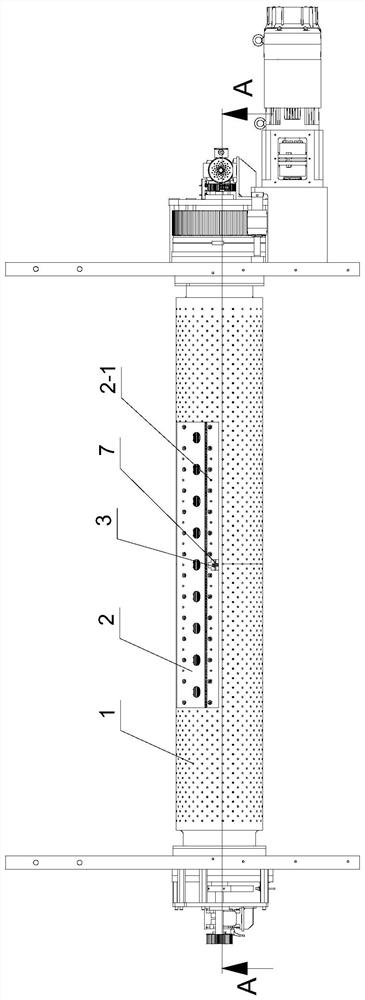

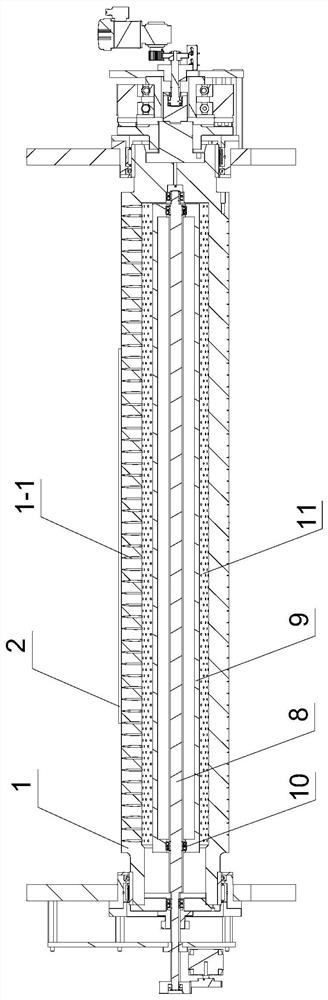

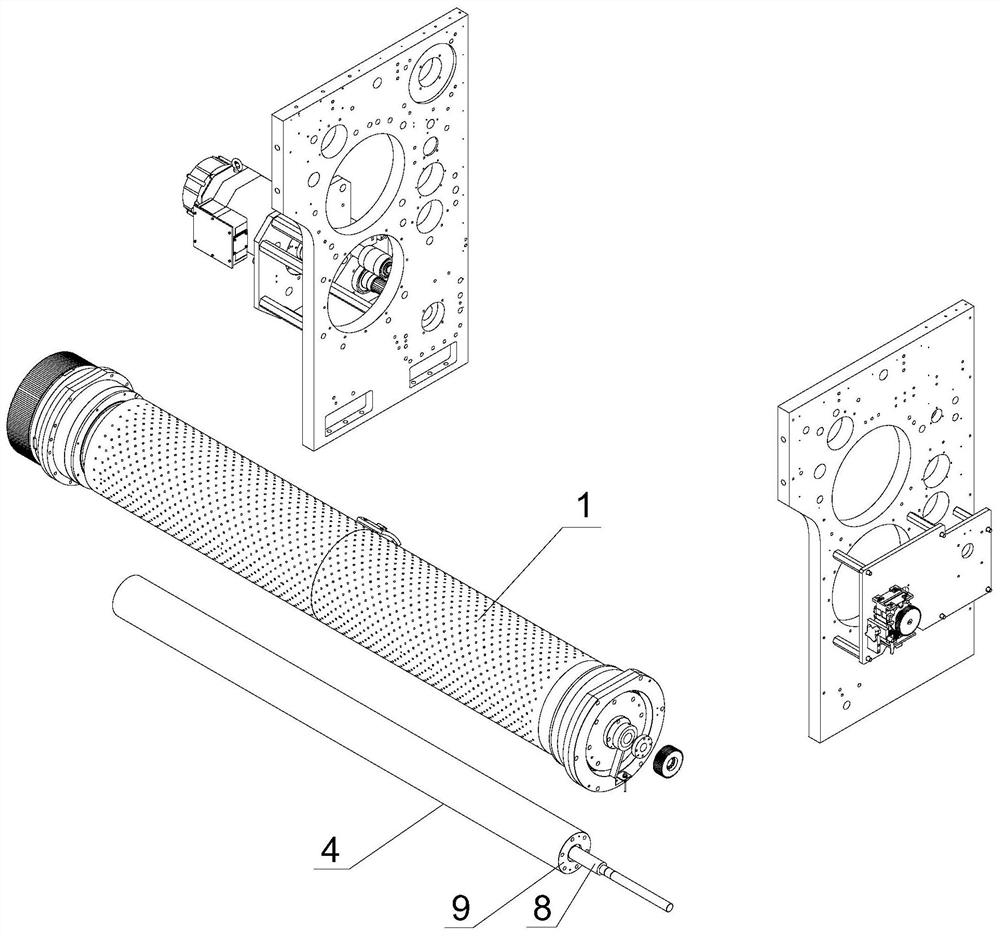

[0031] In this embodiment, a kind of thimble type chip removal device for corrugated paper die-cutting unit, such as Figure 1 to Figure 3 As shown, including die-cutting roller 1, descaling needle ( Figure 1 to Figure 3Not shown), the fixed plate 2, the shrapnel 3 and the eccentric mechanism 4, a plurality of first through holes 1-1 are distributed on the die-cutting roller, the surface of the die-cutting roller is provided with a fixed plate, and the fixed plate is provided with the first through hole 1-1. The second through hole 2-1 with the same holes, and a shrapnel is arranged above the second through hole, and one side of the shrapnel is hinged on the fixed plate; the eccentric mechanism is set in the die-cutting roller, and the desquamation needle is set in the first through hole. And the bottom of each desquamation needle is in contact with the surface of the eccentric mechanism; the number of first through holes is greater than or equal to the number of desquamation...

Embodiment 2

[0037] This embodiment is a thimble-type chip removal device for a corrugated paper die-cutting unit. Compared with Embodiment 1, the difference is that the eccentric mechanism includes a wheel shaft, an eccentric wheel, and a thimble cylinder arranged in sequence from the inside to the outside. There are multiple eccentric wheels, and each eccentric wheel is located in the thimble cylinder, and the two ends of the thimble cylinder are respectively connected to the wheel shaft through bearings. There is a space for the desquamation needle to move between the outer surface of the thimble cylinder and the inner surface of the die-cutting roller. The bottom of the needle is in contact with the outer surface of the thimble barrel. In this structure, the thimble cylinder moves synchronously with the die-cutting roller, and under the action of the bearing, it moves relative to the eccentric wheel and the wheel shaft, so that the width of the descaling needle's activity space changes ...

Embodiment 3

[0039] A kind of thimble-type chip removal method for corrugated paper die-cutting unit of this embodiment can be realized by the thimble-type chip removal device described in embodiment 1 or embodiment 2, such as Figure 4 to Figure 7 As shown, specifically: during the rotation of the die-cutting roller, the descaling needle, the fixed plate and the shrapnel rotate synchronously with the die-cutting roller, and move relative to the eccentric mechanism; when the die-cutting roller is in the die-cutting state, the desquamation The needle shrinks in the first through hole on the die-cutting roller, and the shrapnel covers the second through hole on the fixed plate; The hole and the second through hole are gradually ejected, and the shrapnel is pushed away, and the waste paper or paper scraps are removed by the shrapnel; when the desquamation is completed, the desquamation needle gradually shrinks, and the die-cutting roller enters the die-cutting state in a cycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com