Raw material discharging device provided with anti-blocking structure and used for processing wood board

A wood and anti-blocking technology, which is applied in the direction of wood processing equipment, manufacturing tools, thin material processing, etc., can solve the problems of blockage of the discharge port, affecting work efficiency, and heavy workload, so as to prevent blockage and uneven feeding , to avoid the effect of carrying back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

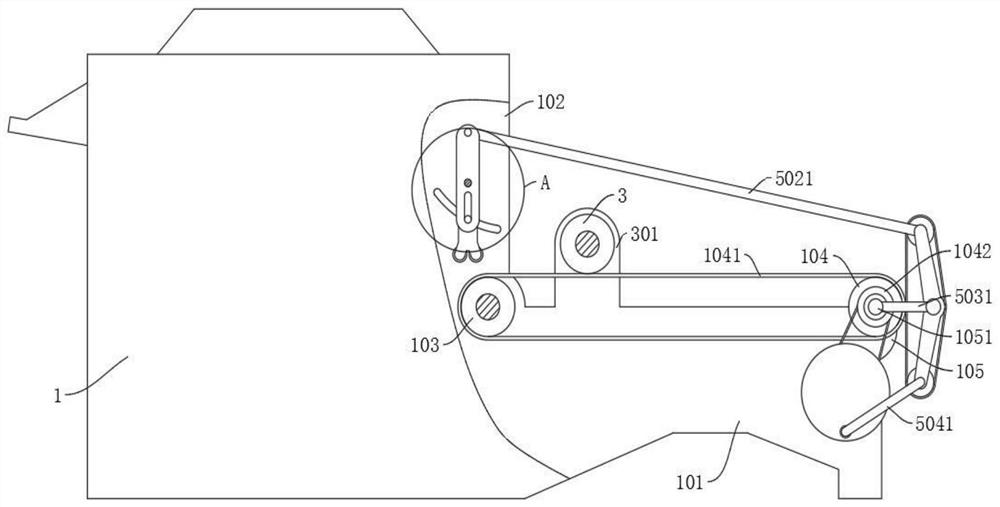

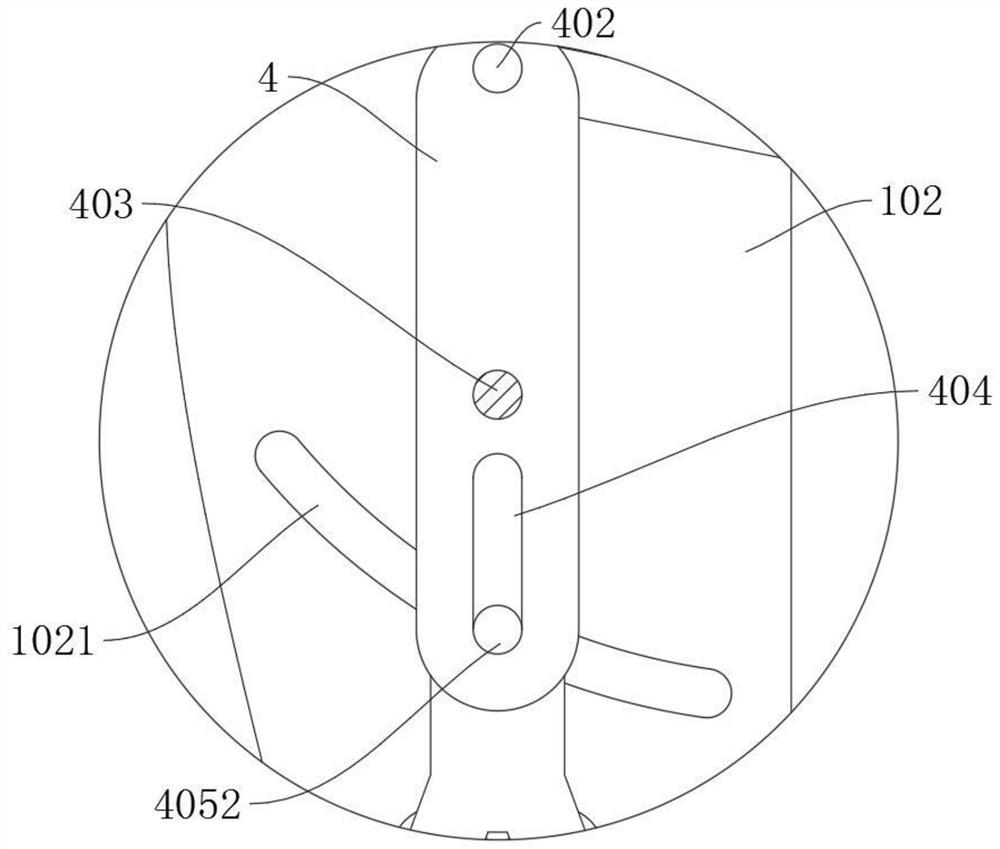

[0030] refer to Figure 1-6, a raw material blanking device for wood board processing with an anti-blocking structure, comprising a wood slicer body 1 and a material guide table 101 fixedly connected to the wood slicer body 1, the slicer body 1 is provided with a discharge port 102 , the discharge port 102 is fixedly connected with a positioning shaft 403, the positioning shaft 403 is rotatably connected with a sleeve rod 4, the sleeve rod 4 is fixedly connected with a fifth rotating shaft 402, the sleeve rod 4 is provided with a guide groove 404, and the sleeve rod 4 is provided with a guide groove 404. A swing rod 405 is slidingly connected, and a guide shaft 4052 is fixedly connected to the swing rod 405. The inner wall of the discharge port 102 is provided with an arc-shaped groove 1021, and the guide shaft 4052 runs through the guide groove 404 and is slidably connected in the arc-shaped groove 1021. The bottom of the swing rod 405 The pusher roller 4051 is connected in r...

Embodiment 2

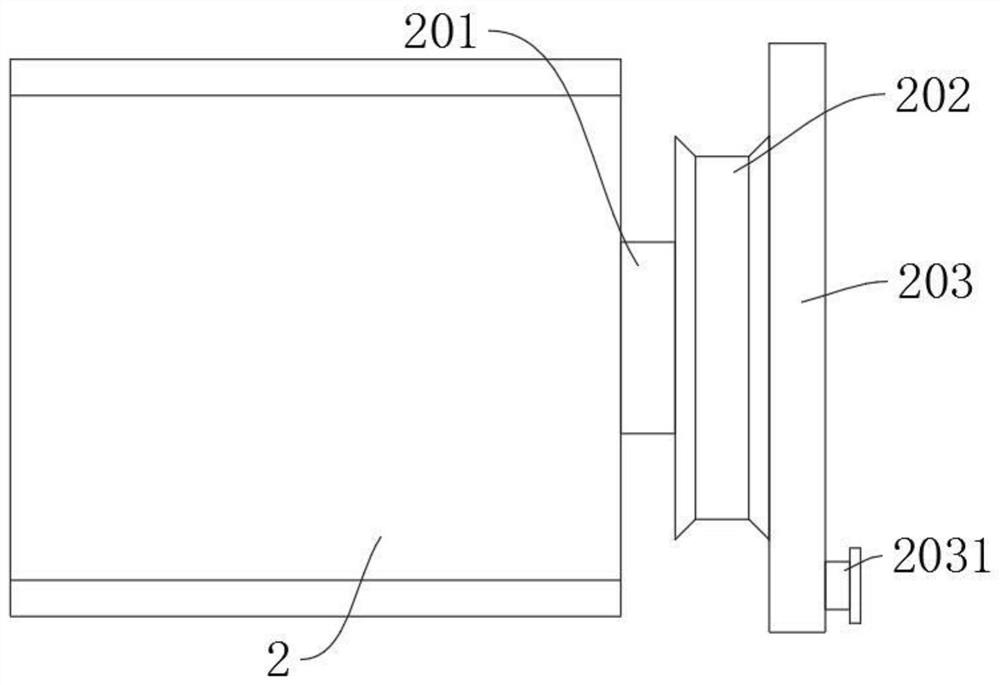

[0033] refer to figure 1 , is basically the same as Embodiment 1, furthermore, the conveying mechanism includes a first conveying roller 103 and a second conveying roller 104, the first conveying roller 103 is rotatably connected in the discharge port 102, and the second conveying roller 104 is fixedly connected in On the sixth rotating shaft 1051, the first conveying roller 103 and the second conveying roller 104 are rotationally connected by a conveying belt 1041, and the second conveying roller 104 is fixedly connected with a second pulley 1042, and the second pulley 1042 is connected to the first belt through a belt. The wheels 202 are rotated and connected, and the uniform rotation of the conveyor belt 1041 can ensure that the sliced wood is discharged at a uniform speed, preventing the subsequent stacking mechanism from being uneven.

Embodiment 3

[0035] refer to figure 1 with Figure 5 , which is basically the same as in Example 1, furthermore, the pressing mechanism includes a pressing roller 501 and an auxiliary belt 5011, the auxiliary belt 5011 is attached to the outer wall of the pressing roller 501, and the pressing roller 501 is rotatably connected to the arc-shaped plate 5 Above, the number of nip rollers 501 is specifically three groups, and the three groups of nip rollers 501 are evenly distributed on the arc-shaped plate 5, and the top of the guide table 101 is fixedly connected with the second mount 301, and the second mount 301 rotates An auxiliary roller 3 is connected, and the auxiliary roller 3 is attached to the conveyor belt 1041. The lowermost pressing roller 501 that constitutes the pressing mechanism mainly plays the function of cutting off the thin plate after sectioning. Under the intermittent action of the turntable 203, the thin plate can be effectively regularized And it is evenly stacked and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com