Automatic end cover locking mechanism for centrifugal mould

A locking mechanism and automatic technology, applied in the direction of coating, etc., can solve the problems of increased mold collection load, rear side panel extrusion recoil, mold material adhesion, etc., to improve the rotation dexterity and sealing degree, Improve the qualified quantity and project speed, and improve the effect of anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

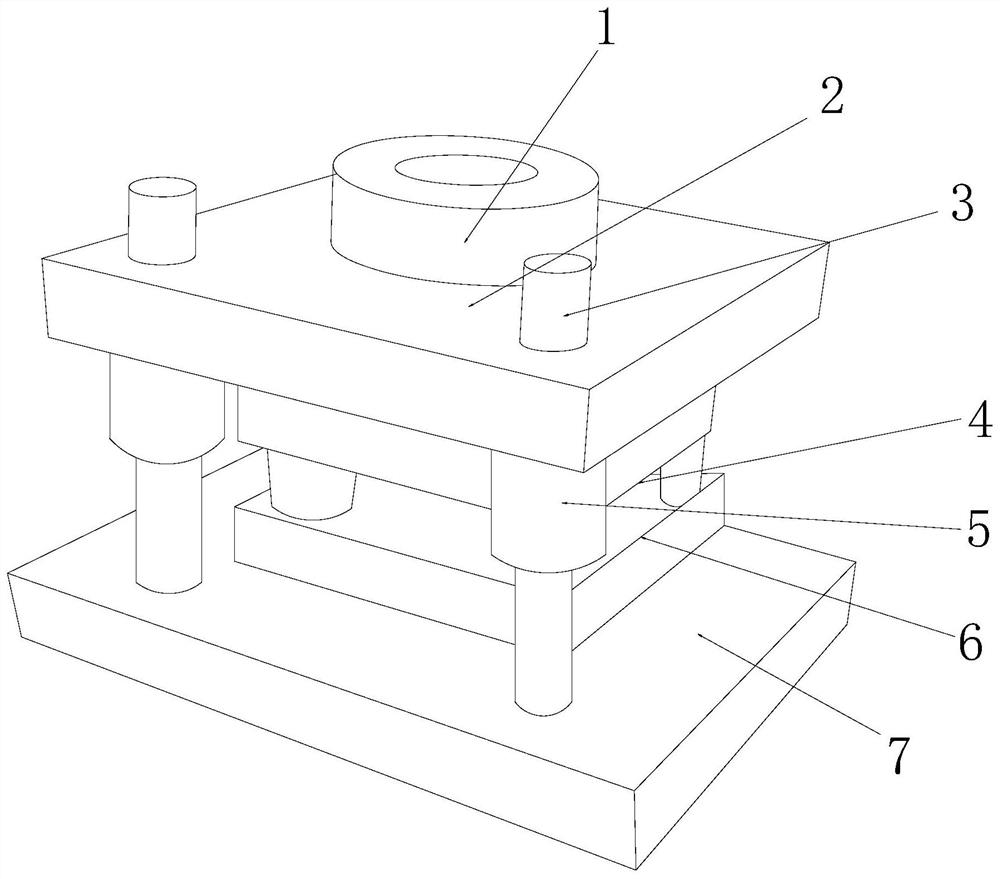

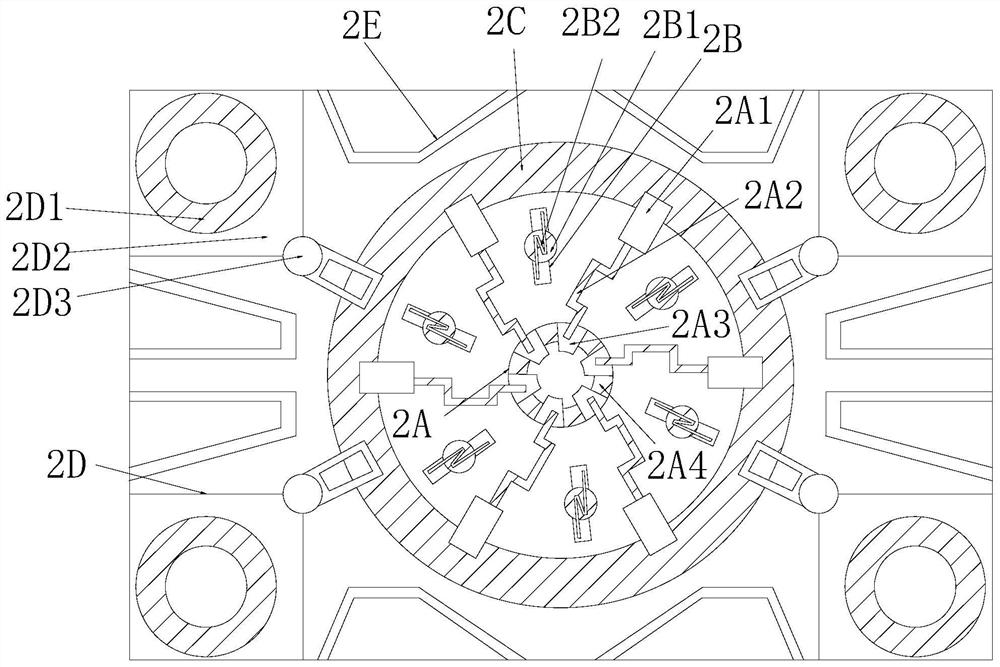

[0032] see Figure 1-Figure 6, the present invention provides a centrifugal mold automatic end cover locking mechanism, its structure includes: locking frame ring block 1, parting locking panel 2, pin rod 3, upper mold groove plate 4, beam sleeve 5, release The mold base 6, the liner plate 7, the parting locking panel 2 is mechanically connected with the mold locking frame ring block 1 and the axes are collinear, and the pin rods 3 are provided with two and respectively vertically penetrate the parting lock Tighten the left and right ends of the front side of the panel 2, the pin rod 3 and the beam sleeve 5 adopt an interference fit and the axes are collinear, and the upper mold groove plate 4 is mechanically connected with the demoulding base 6 and is parallel to each other, so The demoulding base 6 is close to the top surface of the liner plate 7 and is on the same level, and the upper mold groove plate 4 is close to the bottom surface of the parting locking panel 2 and is o...

Embodiment 2

[0039] see Figure 1-Figure 6 , the present invention provides a centrifugal mold automatic end cover locking mechanism, other aspects are the same as embodiment 1, the difference is:

[0040] see figure 2 , the attached sheet buckle frame 2D is composed of a buckle block ring 2D1, a square plate 2D2, and a short buckle frame 2D3. The buckle block ring 2D1 is installed inside the square plate 2D2 and is in the same vertical position. On the straight side, the square plate 2D2 is buckled together with the buckle short frame 2D3, and the corners of the square plate 2D2 are cushioned by the buckle block ring 2D1 to form a clamping effect to ensure the protection of the pins. The completeness and fluency of interspersed.

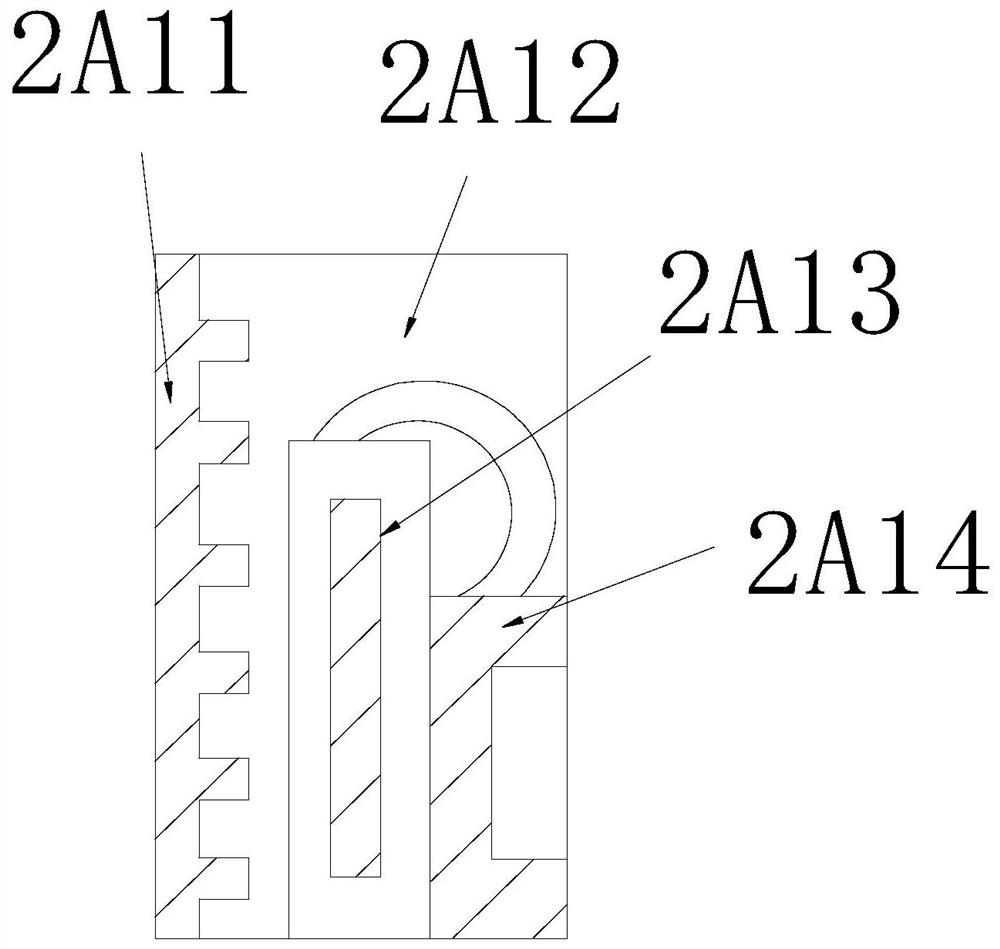

[0041] see Image 6 , the buckle block wheel ring 2D1 is composed of a seal ring 2D11, an elliptical pad gradient block 2D12, and a buckle column block 2D13. The gradient block 2D12 and the buckle column block 2D13 are installed inside the sealing ring 2D11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com