Heater for semiconductor graphite thermal field and heating method thereof

A technology for semiconductors and heaters, applied in chemical instruments and methods, crystal growth, and self-melting liquid pulling methods, etc., can solve problems such as thread and thread hole damage, bolts are not easy to disassemble, etc., to improve stability and avoid repetition The effect of removing bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

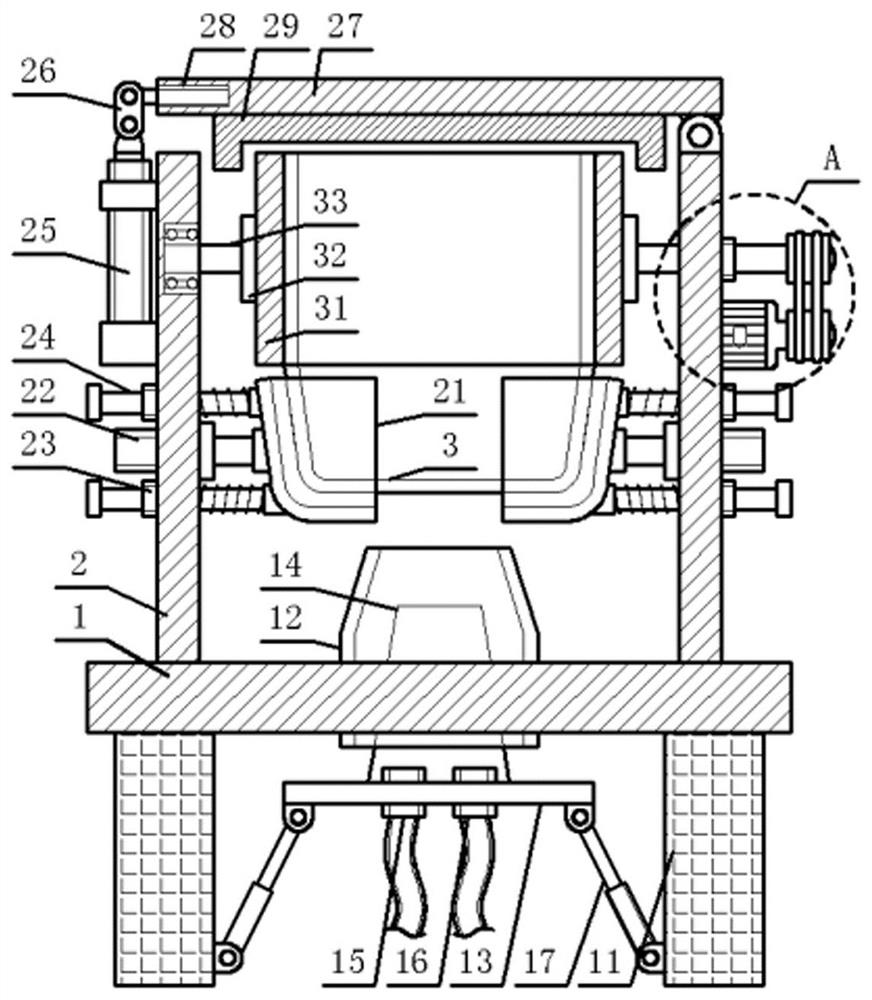

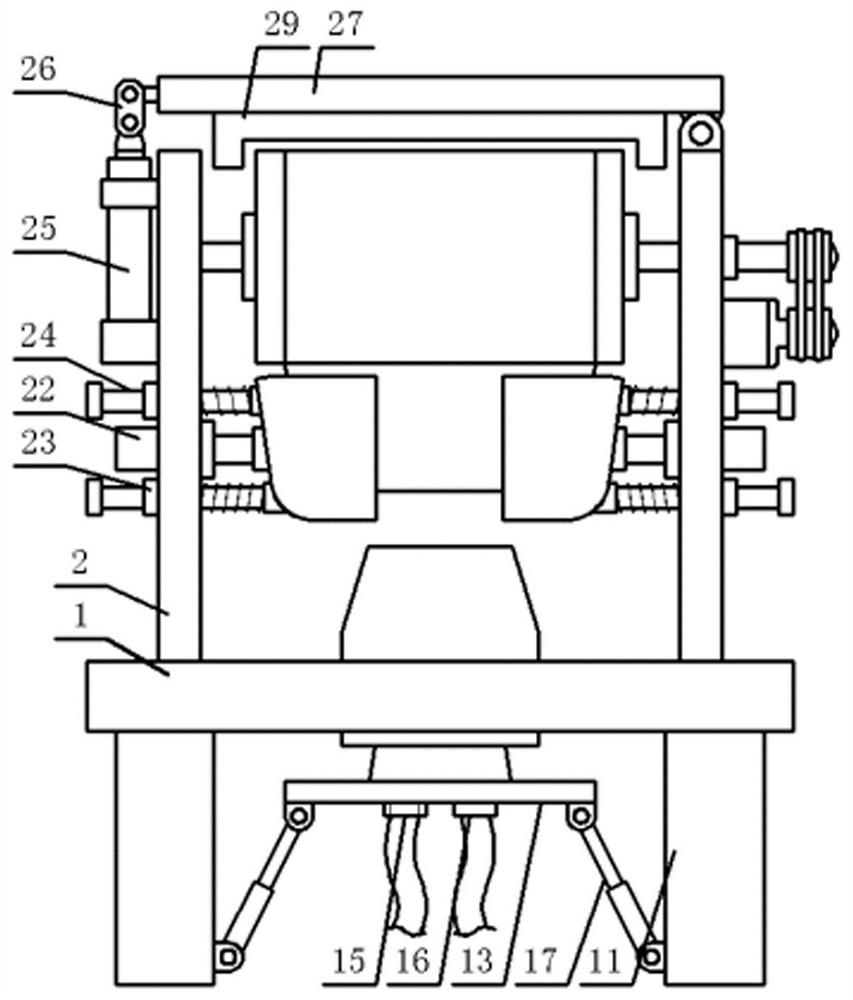

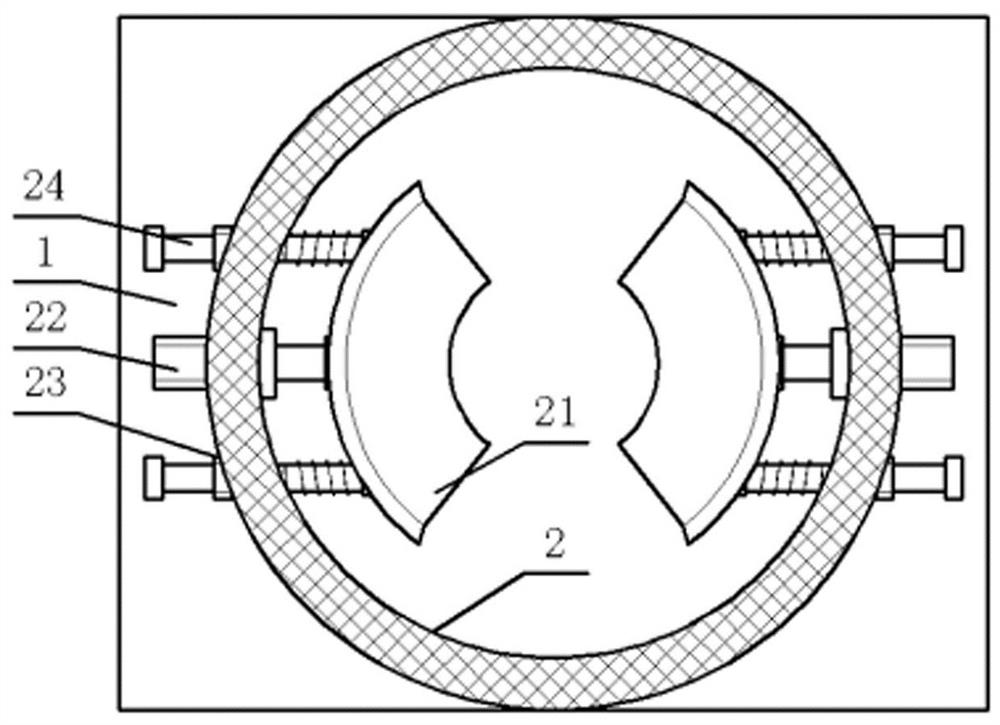

[0031] Embodiment 1: In order to solve the problem that the bolt is difficult to disassemble and improve the stability of crucible heating, a heater for the semiconductor graphite thermal field is proposed in this embodiment, see Figure 1-4 , including a base plate 1, an ignition mechanism, a clamping mechanism, a drive mechanism, and a hinge mechanism. The base plate 1 is a rectangular plate placed horizontally and horizontally. The four corners of the bottom surface of the base plate 1 are provided with support columns 11, which are located at the support Between the columns 11, an ignition mechanism is provided on the bottom surface of the bottom plate 1; the top surface of the bottom plate 1 is provided with an outer cylinder 2 placed vertically and the top surface is open, and the inner top of the outer cylinder 2 is provided with a crucible 3 placed vertically, A pair of clamping mechanisms are provided on the outer cylinder 2 on both sides of the bottom of the crucible ...

Embodiment 2

[0036] Example 2: see Figure 5 , in the present embodiment, the present invention also proposes the heating method of the heater that semiconductor graphite thermal field is used, comprises the following steps:

[0037] Step 1, the hinged cylinder 17, clamping telescopic cylinder 22, drive motor 36, fixed telescopic cylinder 25, and positioning telescopic cylinder 28 are electrically connected to the external power supply through the external power line in turn; pour the graphite material to be heated into the crucible 3;

[0038] Step 2, after the graphite material is poured in, the crucible 3 is controlled to slightly swing and oscillate back and forth through the driving mechanism, and the driving motor 36 is controlled to start, and the motor shaft of the driving motor 36 drives the driving belt 38 to rotate synchronously through the first pulley 37, and then passes through the second The belt pulley 39 drives the driving shaft 34 to rotate in the drum 35, and then drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com