Efficient water washing tank

A washing box, high-efficiency technology, applied in high-pressure cleaning, liquid/gas/steam removal with squeeze rollers, textile material carrier treatment, etc., can solve the problems of reduced cleaning effect and efficiency, unstable fabric transmission, large water resource consumption, etc. Problems, to achieve the effect of strengthening rinsing, improving the effect, and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

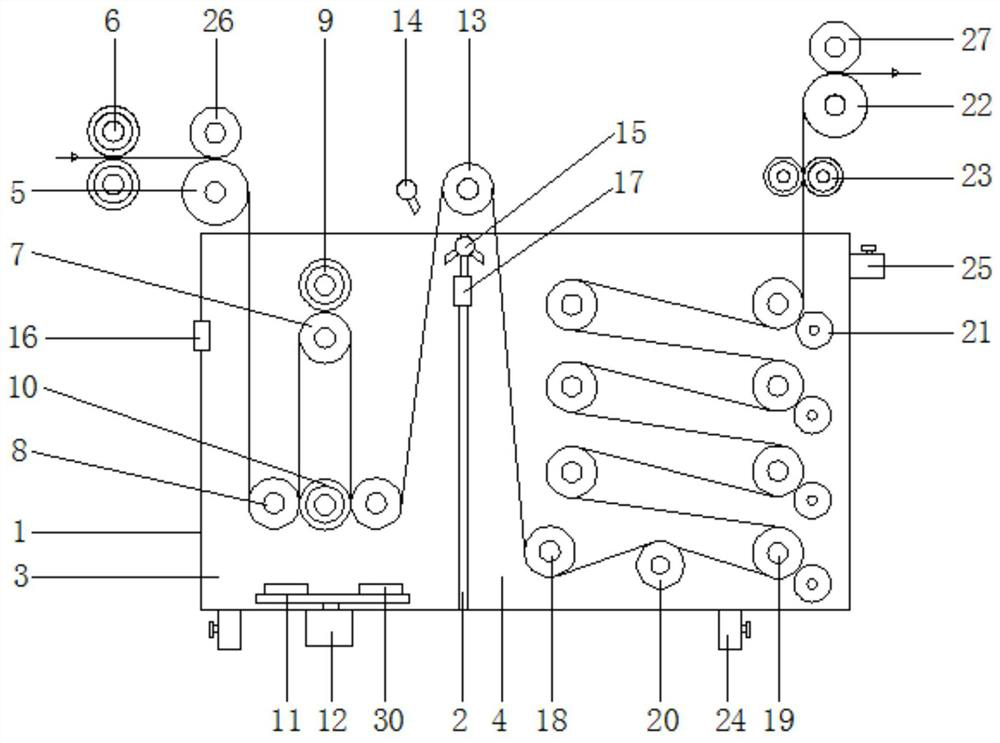

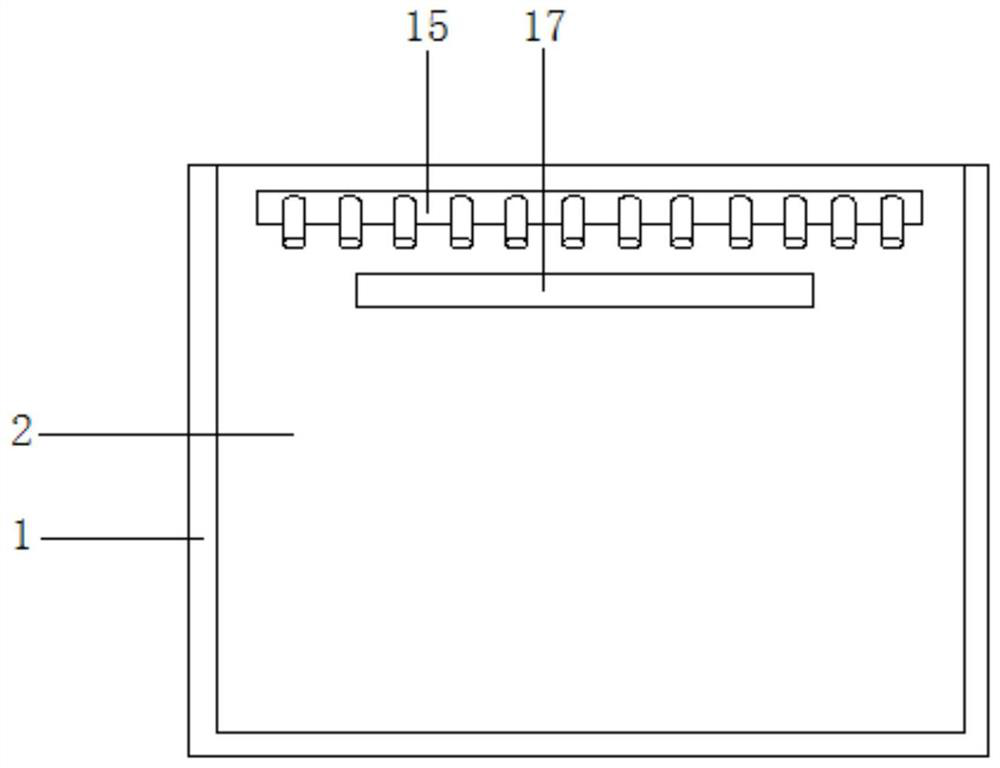

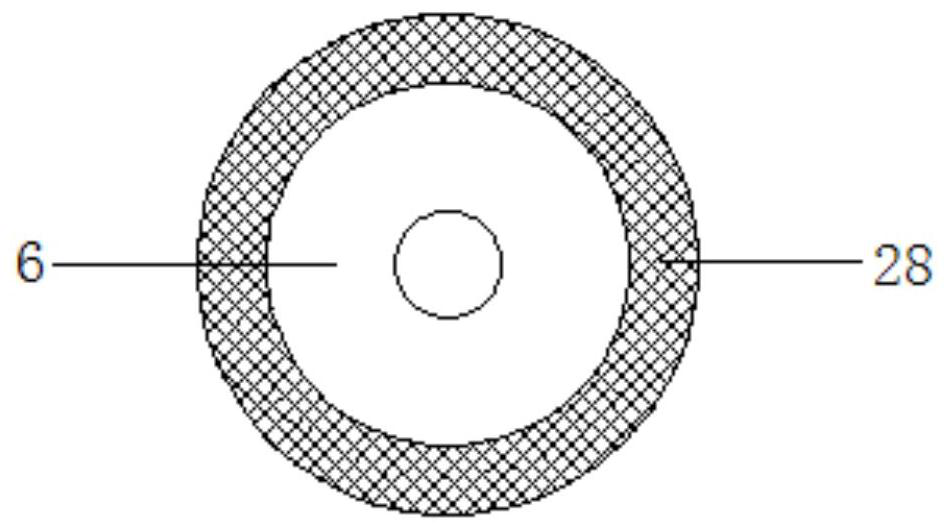

[0027] see Figure 1-Figure 7 As shown, the present invention provides a technical solution: a high-efficiency washing box, including a box body 1, the inner cavity of the box body 1 is connected with a vertical partition 2, and the left and right sides of the vertical partition 2 are respectively formed with The pre-washing box 3 and the rinsing box 4 can pre-wash the fabric, remove the dirt on the surface of the fabric, and then fully rinse to make the cleaning cleaner. The top of the pre-washing box 3 is connected with a feed guide roller rotating on the left side 5. There are two dust removal rollers 6 on the left side of the feed guide roller 5, and the dust removal rollers 6 are bonded and connected to remove floating dust and debris on the surface of the fabric, reducing the burden of pre-washing. The top and bottom of the inner chamber of the pre-washing box 3 are respectively rotatably connected with an upper cloth guide roller 7 and a lower cloth guide roller 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com