Guide roller mechanism for pavement laying and withdrawing

A technology of pavement laying and guiding rollers, which is applied in the direction of roads, roads, road repairs, etc., can solve problems such as skewing and easy deviation of paving vehicles, and achieve the effects of simple structure, low cost and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

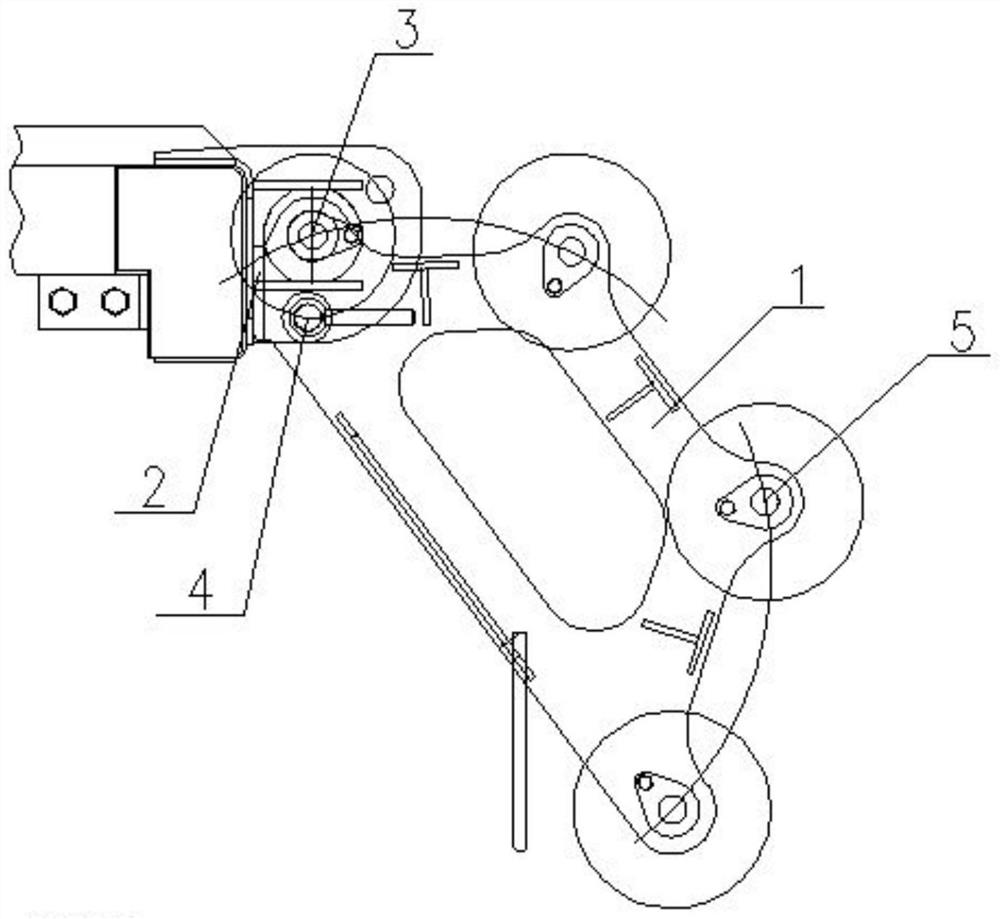

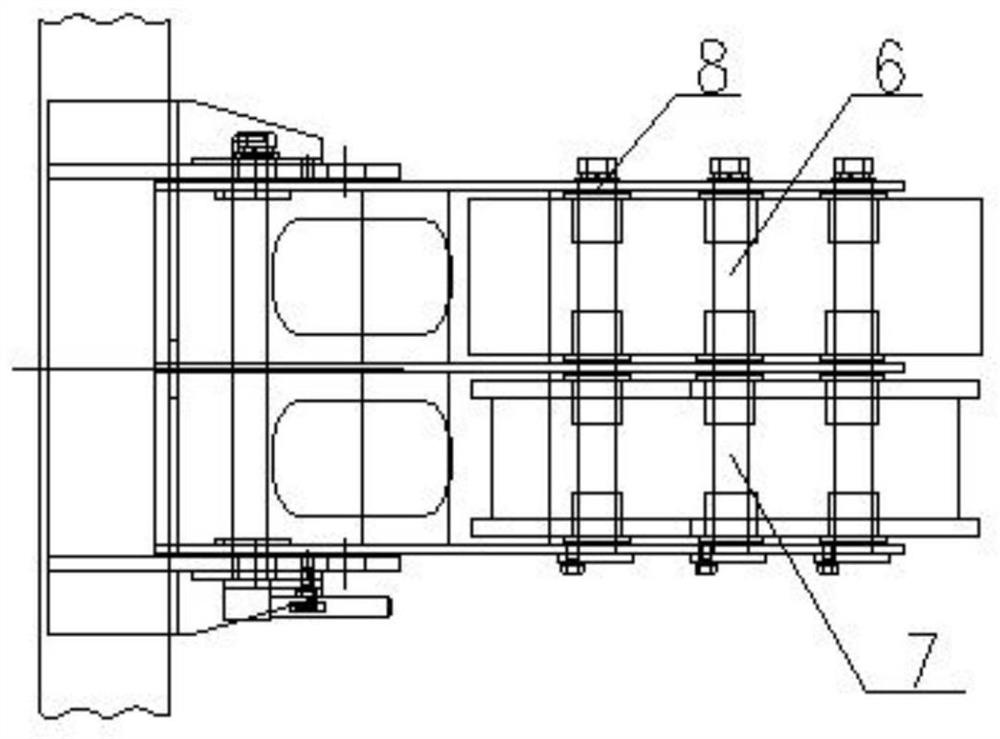

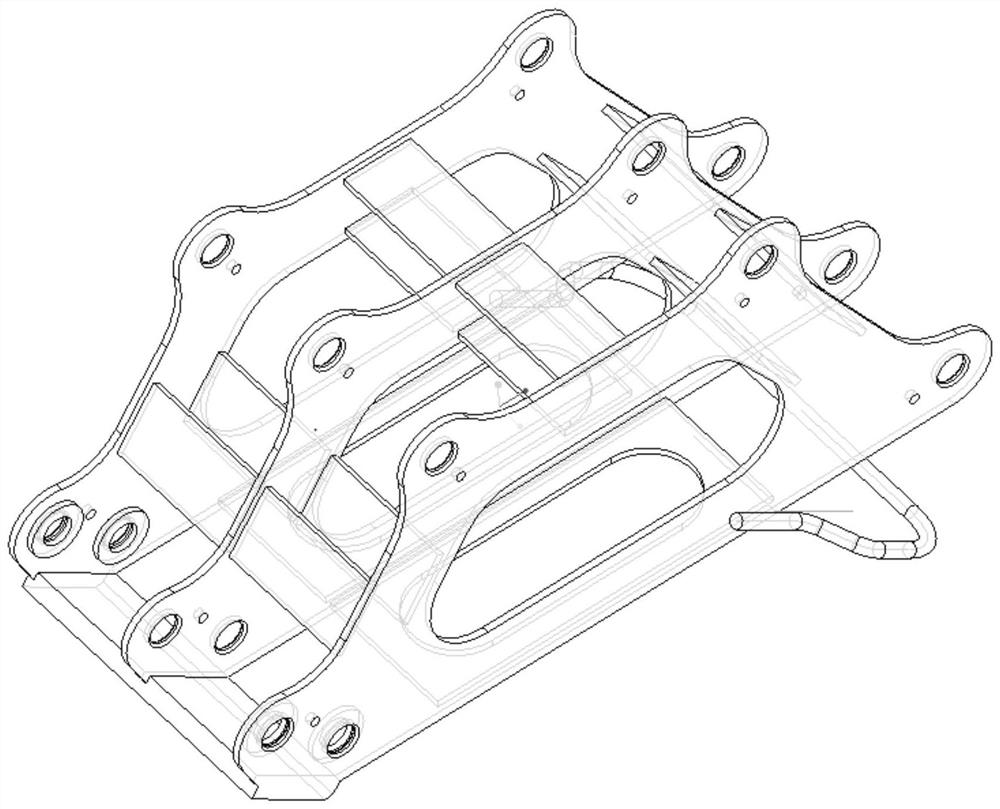

[0026] This embodiment provides a guide roller mechanism for pavement laying and withdrawing, see the attached Figure 1-2 , including: roller support 1, fixed support 2, rotating shaft 3, pin shaft 4, wheel shaft 5, roller 6, guide wheel 7 and bushing 8;

[0027] The fixed support 2 is a U-shaped frame; the bottom plate of the U-shaped frame is fixed on the tail beam of the road laying vehicle by welding; the two side plates of the U-shaped frame are processed with the same connection hole A and limit hole A and the limit hole B; the distance between the center of the limit hole A and the limit hole B and the center of the connection hole A is 75mm, and the distance between the center of the limit hole A and the limit hole B and the connection hole A The angle formed between the lines connecting the centers of the circles is 128°;

[0028] See attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com