A kind of steel structure exterior wall dry hanging integrated board and installation method

A technology of steel structure and integrated board, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of easy corrosion, low efficiency, and affecting the transportation and installation of external wall hanging boards, and improve the connection strength and connection reliability , Improve construction efficiency and reduce the effect of assembly and disassembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

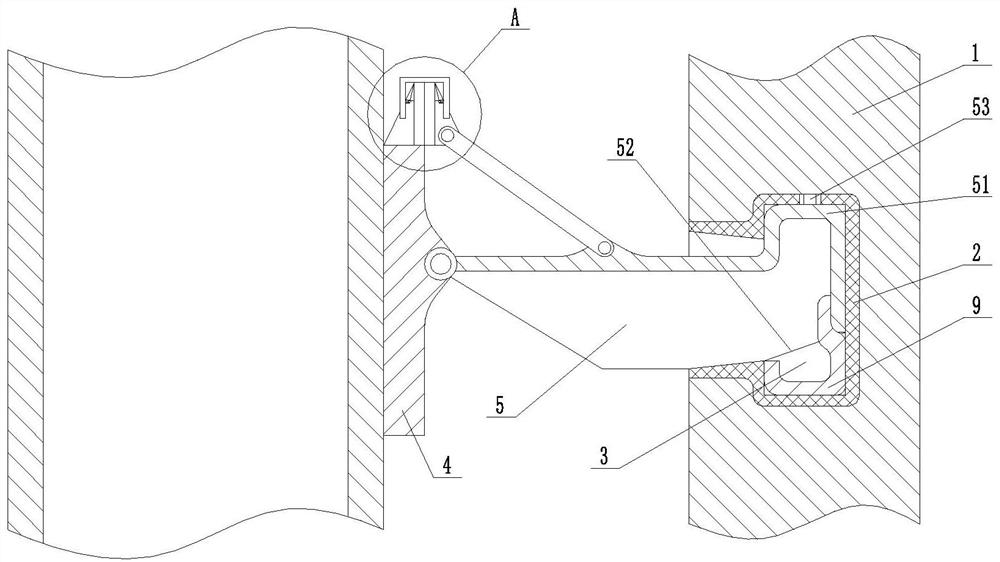

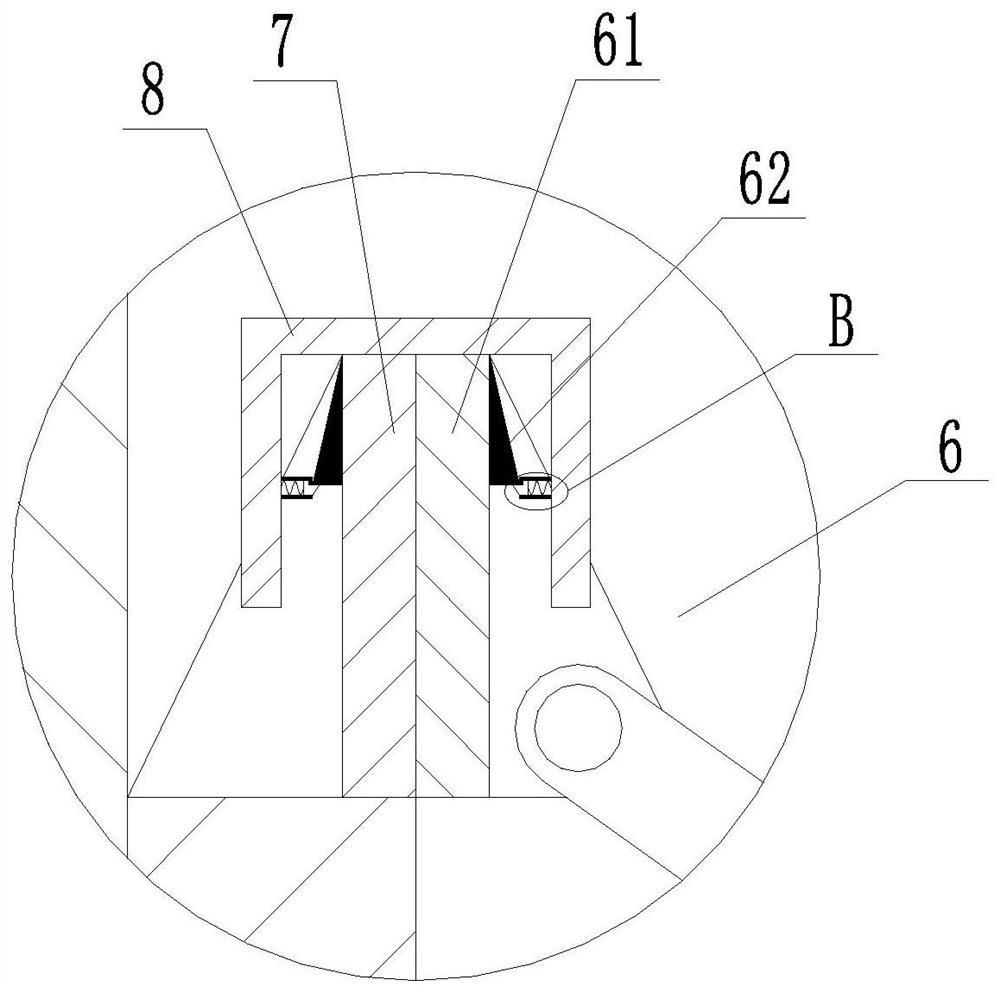

[0036] like figure 1 As shown, a steel structural exterior wall dry-mounted panel, including prefabricated outer wall hanging plate 1 and a connection assembly used therewith, a prefabricated beam 2 is embedded on one side of the steel structure, and the prefabricated beam 2 2 Prefably the inwardly recess, the recess, the connecting assembly includes the base 4, the connector 5, and the angular adjustment structure, the base 4 is fixed to the outer wall column of the steel structure by a bolt, and one end of the connecting member 5 rotates through the rotary shaft On the base 4, the other end of the connector 5 is provided with a convex portion 51 and the guide portion 52, and the angle adjustment structure is mounted on the base 4, and the connecting member 5 under the angular adjustment structure is entered into the mounting groove through the guide portion 52. 3 Match the connection with the mounting groove 3 by the convex portion 51.

[0037] Specifically, when used, the base ...

Embodiment 2

[0045] A mounting method for drying a steel structure exterior wall, including the following steps:

[0046] A. First fix the base 4 in the connection assembly on the outer wall column of the steel structure;

[0047] B. Subsequently, the preformed outer wall hanging plate 1 is lifted to the outer wall hanging plate 2 and the connector 5 rotation node is located at the same horizontal plane;

[0048] C. Adjusting the angle control unit 61 drives its own angle control unit 61 to move toward the position plate 7, the guiding portion 52 of the connector 5 during which the connecting member 5 is guiding the connecting member 5 to be gradually inserted into the mounting groove 3 in the end of the base 4. When the restricted plate 7 is bonded to the angle control unit 61, the boss portion 51 cooperates with the mounting groove 3 and the positioning member 53 at the top of the convex portion 51 is fitted to the through hole on the preformed beam 2;

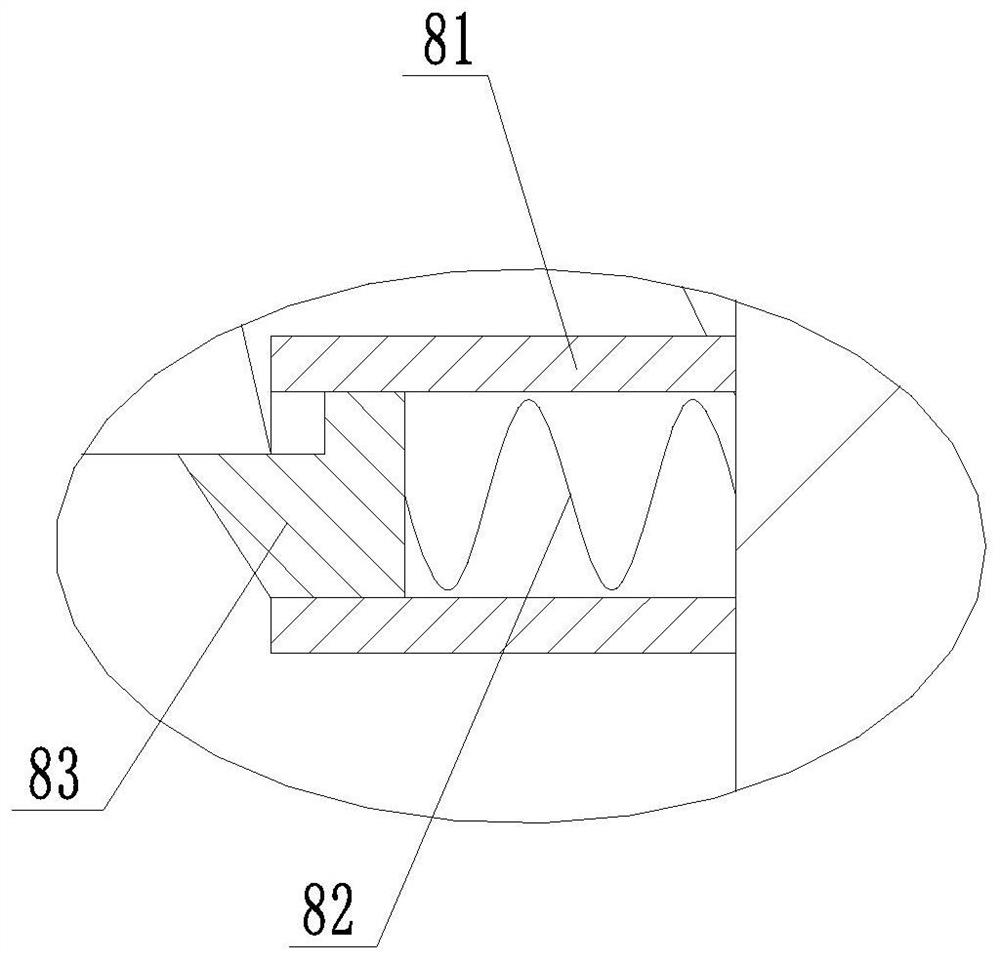

[0049] D. The locking member 8 is pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com