A high-efficiency cooling and heating system based on the combined operation of heat source towers and ice storage

A technology for a heating system and a heat source tower, applied in the field of high-efficiency cooling and heating systems, can solve the problems of restricting the application of heat source tower heat pump systems, large equipment footprint, and low energy efficiency of heat pump units, so as to improve energy utilization and equipment. The effect of high utilization rate and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

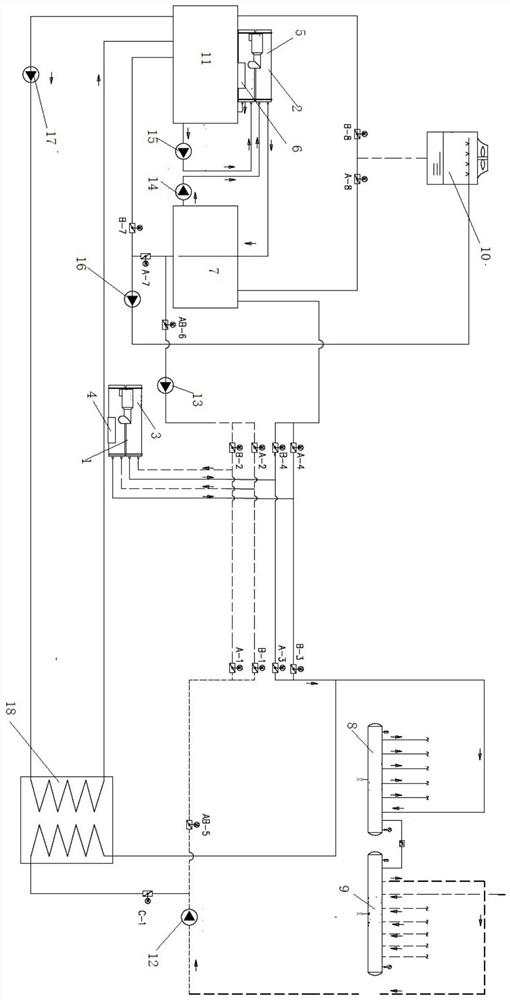

Embodiment 1

[0022] The first valve A-1, the third valve A-3, the fifth valve A-4, the seventh valve A-7, the ninth valve A-8, the eleventh valve A-2 are closed, and the second valve B-1 , the fourth valve B-3, the sixth valve B-4, the eighth valve B-7, the tenth valve B-8, the twelfth valve B-2 open, the thirteenth valve AB-5 and the fourteenth valve AB-6 is open and the fifteenth valve C-1 is closed.

[0023] The user-side water pump enters the first condenser 4 in the main heat pump unit 1 through the thirteenth valve AB-5 and through the second valve B-1, the water temperature rises from 40°C to 45°C, and then passes through the fourth valve B-3 Enter the water distributor 8 to provide 45°C hot water to the user, and the cooled 40°C hot water returned from the user side enters the water collector 9 and then enters the inlet of the user water pump 12 to complete the hot water cycle; the medium temperature water at 25°C passes through the first The fourteenth valve AB-6 enters the mediu...

Embodiment 2

[0026] The second valve B-1, the fourth valve B-3, the sixth valve B-4, the eighth valve B-7, the tenth valve B-8, the twelfth valve B-2 are closed, the first valve A-1 , the third valve A-3, the fifth valve A-4, the seventh valve A-7, the ninth valve A-8, the eleventh valve A-2 open, the thirteenth valve AB-5 and the fourteenth valve AB-6 is open and the fifteenth valve C-1 is closed.

[0027] The cold water at 12°C enters the user water pump 12 from the water collector 9, and then enters the first evaporator 3 in the main heat pump unit 1 through the thirteenth valve AB-5 and the first valve A-1. After the temperature drops to 7°C, it passes through The third valve A-3 enters the water separator 8, and the temperature of the cold water in the water separator 8 rises to 12°C after absorbing heat from the room and flows back to the water collector 9 to complete the cold water cycle; the medium temperature water at 30°C passes through the fourteenth valve AB-6 flows into the m...

Embodiment 3

[0030] The ice water source heat pump unit 2, the ice water circulation pump 15, the medium temperature circulation pump 14, and the tower water pump 16 open the seventh valve A-7 and the ninth valve A-9, and close other equipment and valves.

[0031] The cooling water at 30°C enters the second condenser 5 in the ice water heat pump unit 2 through the medium-temperature circulating water pump 14, and flows back to the medium-temperature water tank 7 after the temperature rises to 35°C, and the hot water at 35°C passes through the seventh valve A-7 Enter the tower water pump 16, and then flow into the cooling tower to dissipate heat. After the temperature drops to 30°C, it enters the medium temperature water tank 7; the cold water at 0°C enters the second evaporator 6 in the ice water source heat pump unit 2 through the ice water circulation pump 15, and part of the water It solidifies into ice and falls into the ice water tank 11 under the action of gravity and the action of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com