System for continuously measuring permeability of sintered mixture and measuring method thereof

A technology of sintering mixture and air permeability, which is applied in the field of metallurgical sintering, can solve the problem that the sintering mixture cannot be continuously measured online, and achieve the effect of convenient operation, simple system structure and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

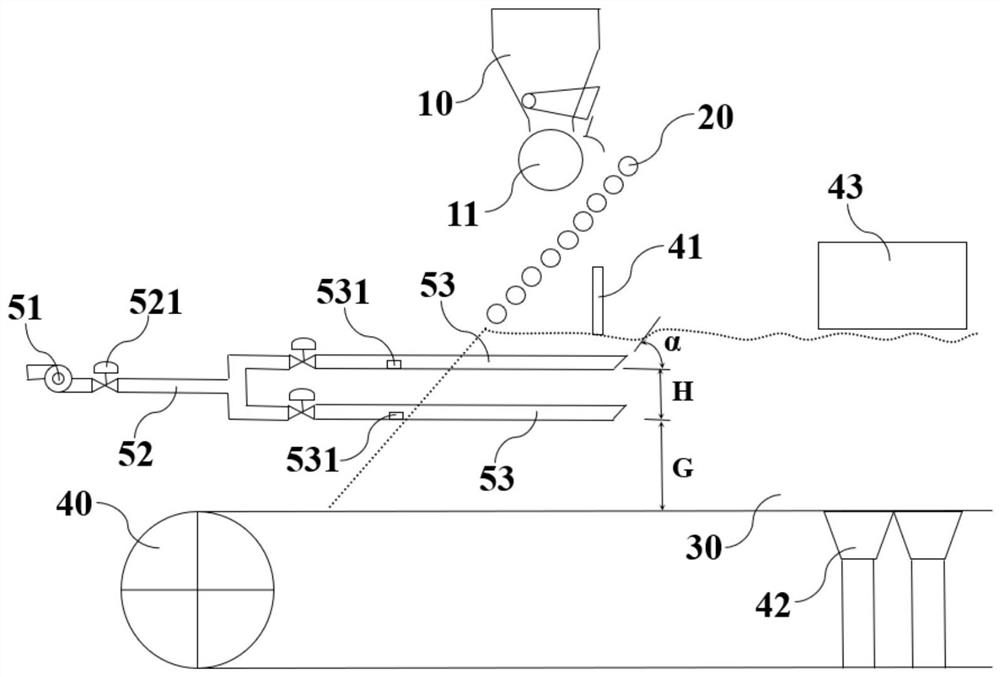

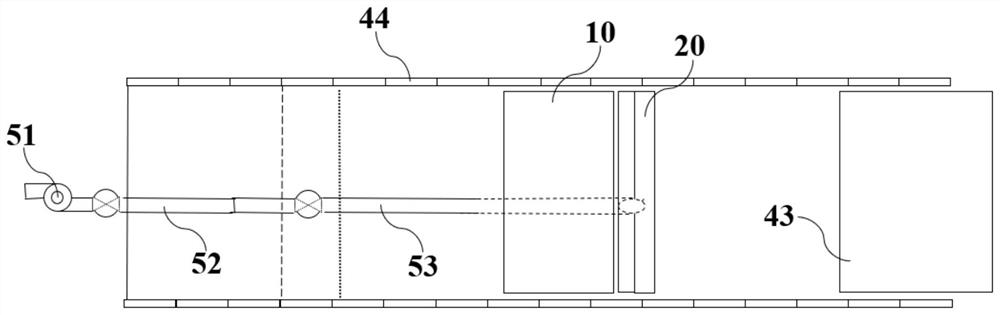

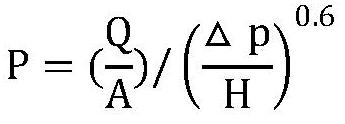

[0035] A system for continuously measuring the air permeability of the sintering mixture in this embodiment includes a mine tank 10, a distributor 20, and a sintering machine, wherein the sintering machine includes a sintering trolley, a monolithic board 41, a fan 42, an ignition furnace 43, and a fence 44 , combined with figure 1 and figure 2 , the mine tank 10 is used to store the mixed material 30, and the mixed material 30 is sent to the distributor 20 through the feeder 11 at the bottom of the mine tank 10, and the mixed material 30 is evenly transported to the sintering trolley by the distributor 20, and the whole Under the action of the material plate 41, the uniformity of the height of the mixture 30 is ensured.

[0036] It is worth noting that the distributor 20 of this embodiment adopts a nine-roller distributor, and the distributor 20 is installed obliquely, and under the action of the star wheel 40 of the sintering trolley, the mixture 30 is evenly distributed on...

Embodiment 2

[0051] A system for continuously measuring the gas permeability of the sintering mixture in this embodiment is basically the same as that in Embodiment 1. Furthermore, in this embodiment, the air outlet of the branch pipe 53 is arranged obliquely, and its inclination direction faces the platform of the sintering trolley, such as figure 1 As shown, the inclination angle is α, and 0<3α≤35°, which can be 10°, 15°, 20°...25° or 35°.

[0052] Preferably, the inclination angle α is 35°.

[0053] Since the mixture 30 is distributed to the table top of the sintering trolley by the distributor 20, the mixture falls onto the table from above, and one end of the branch pipe 53 is inserted into the mixture 30, the present embodiment controls the inclination The size of the angle and the angle of inclination make the mixture 30 pile up on the table surface, it will not have an effect on the air outlet of the branch pipe 53, thereby reducing the impact on the detection results as much as po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com