Extraction method, detection method and extraction device for flavors and fragrances in food

An extraction method and a technology of flavors and fragrances, applied in the field of chemical detection, can solve the problems of long time, complicated and cumbersome extraction steps, and affect the purification effect, and achieve high recovery rate, thorough stratification, and good signal response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

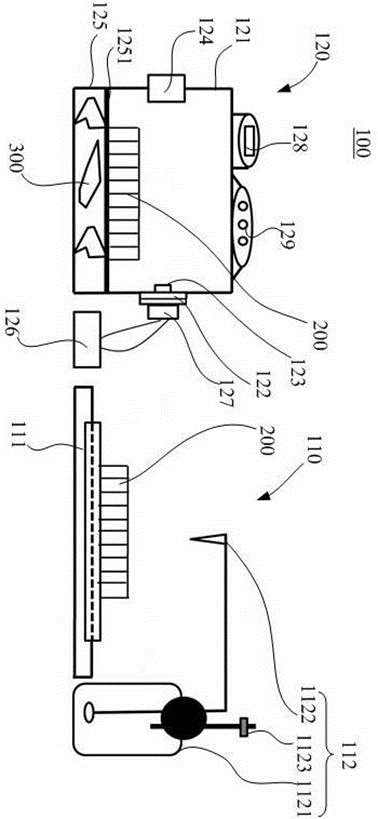

Method used

Image

Examples

Embodiment 1

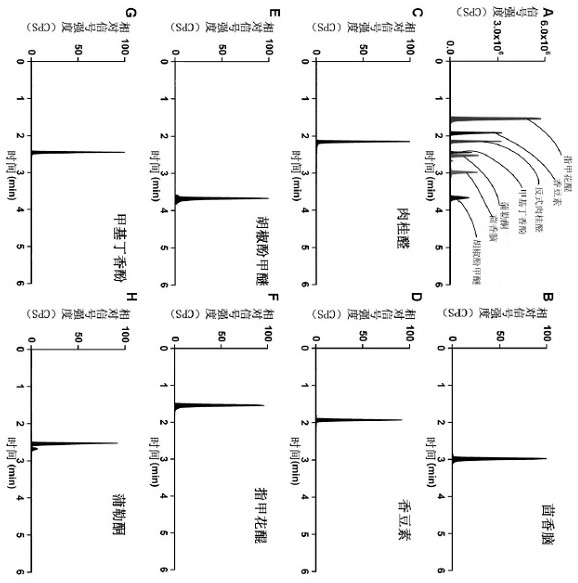

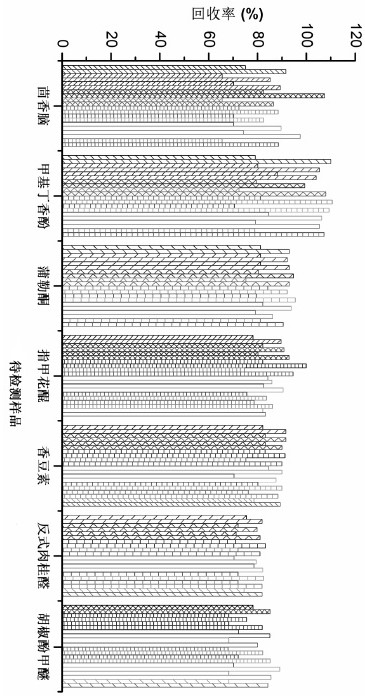

[0114] Embodiment 1, 10 green tea samples are carried out to add standard recovery experiment

[0115] 1 g of 10 green tea samples were placed in colorimetric tubes, and 7 kinds of flavors and fragrances were added to each colorimetric tube to carry out the spike recovery experiment. The spiked concentration was 20 mg / kg, and the spiked volume was 50 μL.

[0116] The 10 samples were extracted by the manual extraction and purification method and the extraction equipment 100 of the present invention, and the recovery rate comparison experiment was carried out, and a total of 140 groups of experiments were performed.

[0117] Using the traditional method: add acetonitrile-water solution (volume ratio: 4:1) to the sample, dilute to 10mL, take 500μL in a centrifuge tube, dilute to 5mL with acetonitrile, add purifying agent (20mg anhydrous magnesium sulfate, 5mgPSA and 5mgGBC), vortexed for 1min, centrifuged at 8000rpm for 1min, took 1mL of the organic phase, filtered it through a 0...

Embodiment 2

[0121] Embodiment 2, carry out standard addition recovery experiment to 10 sterilized milk samples

[0122] 1 g of 10 green tea samples were placed in colorimetric tubes, and 7 kinds of flavors and fragrances were added to each colorimetric tube to carry out the spike recovery experiment. The spiked concentration was 20 mg / kg, and the spiked volume was 50 μL.

[0123] The 10 samples were extracted by the manual extraction and purification method and the extraction equipment 100 of the present invention, and the recovery rate comparison experiment was carried out, and a total of 140 groups of experiments were performed.

[0124] Using the traditional method: acetonitrile-water solution (volume ratio: 4:1) was adjusted to 10 mL, 500 μL was placed in a centrifuge tube, and the volume was adjusted to 5 mL with acetonitrile, and the purification agent (20 mg anhydrous magnesium sulfate, 5 mg PSA and 5 mg GBC) was added, and vortexed Rotate and mix for 1 min, centrifuge at 8000 rpm ...

Embodiment 3

[0128] Example 3 Carry out standard addition recovery experiment on 5 infant milk powder samples

[0129] For 5 infant milk powder samples, take 2 g and place them in colorimetric tubes respectively, and add the standards of 7 kinds of flavors and fragrances (20 mg / kg, 50 μL) to each colorimetric tube respectively. The solution was subjected to spike recovery experiments.

[0130] The 5 samples were extracted by manual extraction and purification method and the extraction equipment 100 of the present invention, and the recovery rate comparison experiment was carried out, a total of 70 groups of experiments.

[0131] Using the traditional method: dilute to 10 mL with methanol-water solution (4:1 volume ratio), take 500 μL into a centrifuge tube, dilute to 5 mL with methanol, add 40 mg of anhydrous magnesium sulfate, 5 mg of PSA and 5 mg of GBC, vortexed for 1 min, centrifuged at 10,000 rpm for 3 min, took 1 mL of the supernatant, and tested it on a 0.22 μm nylon membrane.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com