Multi-effect evaporator in the production of liquid glucosamine

A glucosamine and multi-effect evaporation technology, applied in the field of multi-effect evaporation devices, can solve the problems of small effective contact area, affecting steam efficiency, and low evaporation efficiency, so as to increase contact area, improve heating efficiency, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

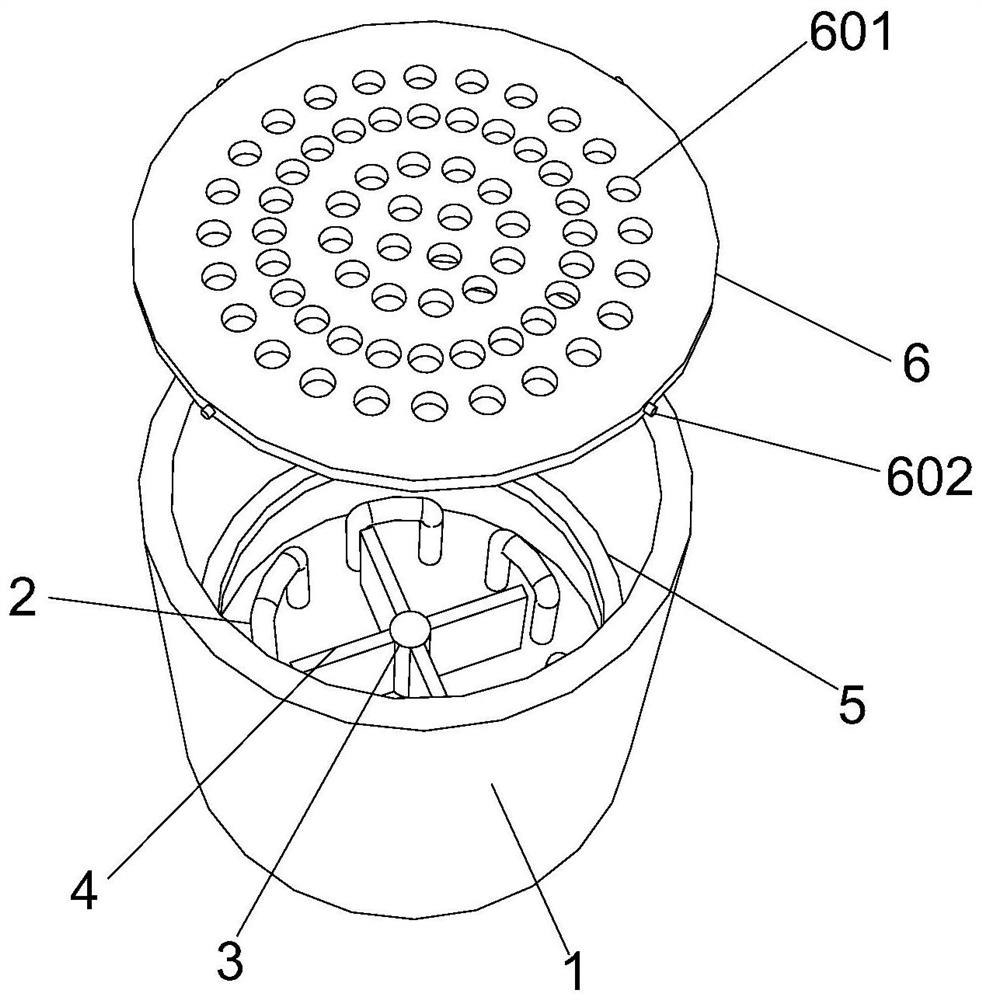

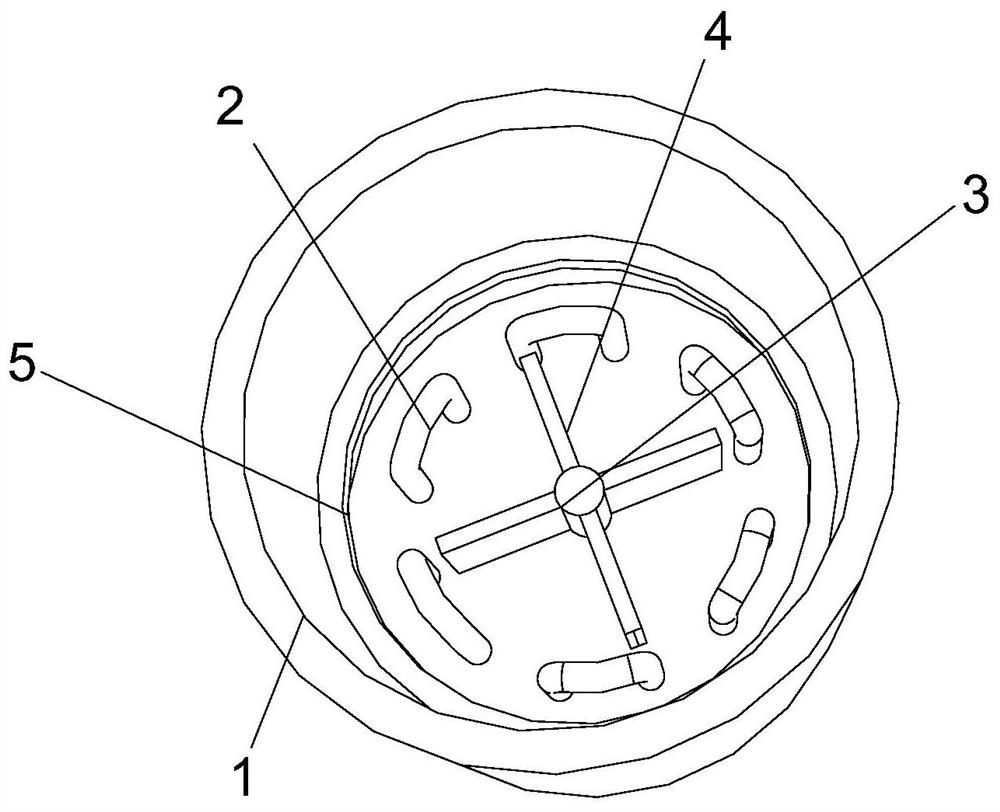

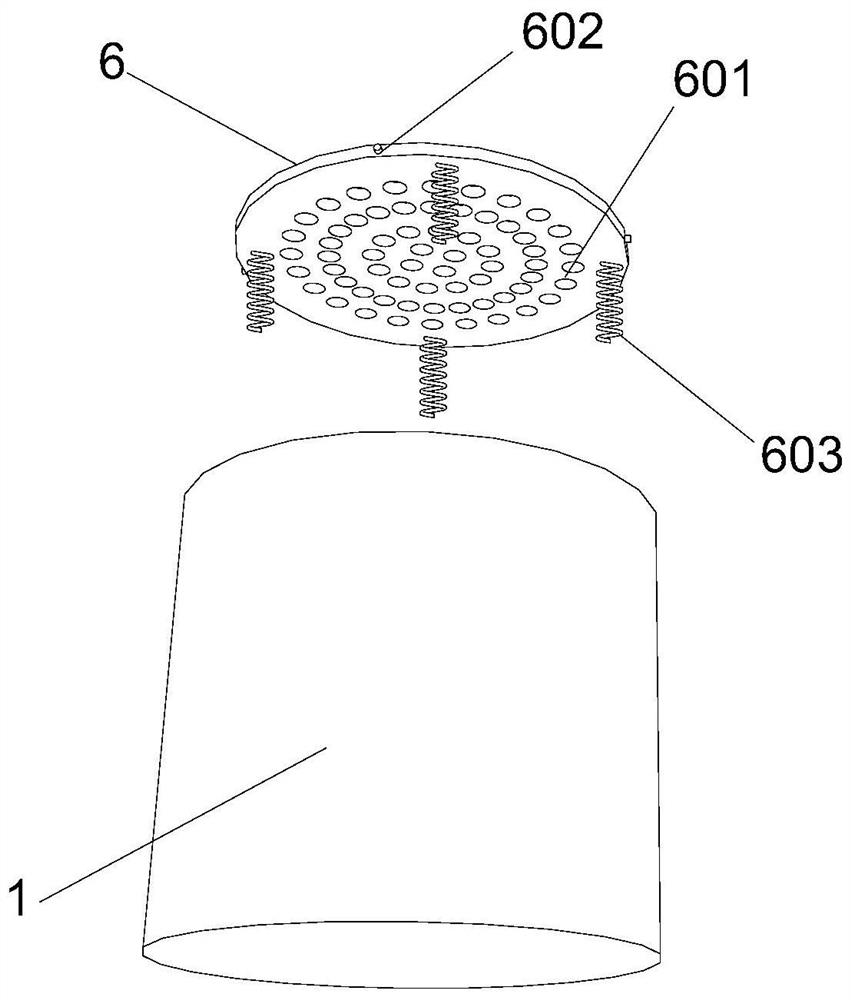

[0028] Embodiment: the multi-effect evaporation device in the production of liquid glucosamine, such as Figure 1-Figure 7 As shown, it includes an evaporating cylinder 1, which is a cylindrical cylinder. The inner low end of the evaporating cylinder 1 is ring-shaped and fixedly installed with a circle of heating tubes 2. The heating tube 2 is an arched ring and the heating tube 2 The lower end extends to the lower end of the evaporating cylinder 1 and is fixed by a nut. The lower end of the heating tube 2 is electrically connected to the external power control device through a wire. A rotating shaft 3 is installed vertically in the middle of the inner bottom of the evaporating cylinder 1. The rotating shaft 3 is a long cylindrical rod, the lower end of the rotating shaft 3 is connected to the inner bottom of the evaporating cylinder 1 through a bearing and the lower end of the rotating shaft 3 extends through the bottom plate of the evaporating cylinder 1 to the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com