Stirring method of adsorption tank

A stirring method and adsorption tank technology, which is applied in the field of biomedicine, can solve problems such as prolonged operation time, clogged filter plates, and gel deformation, so as to ensure product yield and quality, prevent filter plate clogging, and protect gel form. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

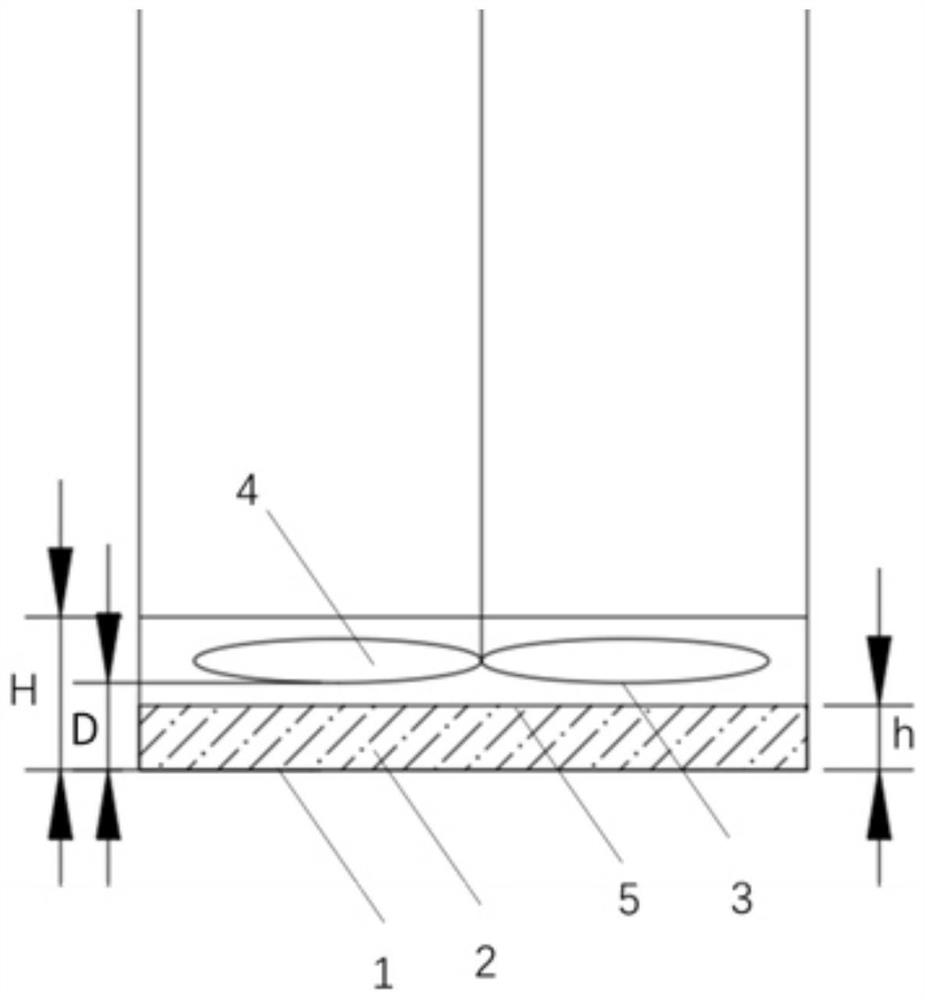

[0043] A stirring method for an adsorption tank, said method comprising (I) adjusting the stirring height according to the amount of gel and (II) selecting a stirrer 4, determining stirring parameters, and stirring;

[0044] The adjustment method of described stirring height comprises the steps:

[0045] (1) According to the amount of plasma absorbed by the gel 1000kg, use 1.5g of gel per kg of plasma, and determine the amount of gel M to be 1500g;

[0046] (2) Determine the minimum expansion ratio K of the gel in the solution m , including the following steps:

[0047] (21) The solution used for gel treatment includes swelling solution, equilibrium solution, washing solution, eluent, regeneration solution and preservation solution, and the swelling solution is 0.075mol / L sodium chloride solution,

[0048] Balance liquid is 0.08mol / L sodium chloride, 0.015mol / L sodium citrate, pH7.2±0.1,

[0049]The washing solution is 0.18mol / L sodium chloride, 0.015mol / L sodium citrate, p...

Embodiment 2

[0065] A stirring method for an adsorption tank, said method comprising (I) adjusting the stirring height according to the amount of gel and (II) selecting a stirrer 4, determining stirring parameters, and stirring;

[0066] The adjustment method of described stirring height comprises the steps:

[0067] (1) According to the amount of plasma absorbed by the gel 1500kg, use 1.2g of gel per kg of plasma, and determine the amount of gel M to be 1800g;

[0068] (2) Determine the minimum expansion ratio K of the gel in the solution m , including the following steps:

[0069] (21) The solution used for gel treatment includes swelling solution, equilibrium solution, washing solution, eluent, regeneration solution and preservation solution, and the swelling solution is 0.075mol / L sodium chloride solution,

[0070] Balance liquid is 0.08mol / L sodium chloride, 0.015mol / L sodium citrate, pH7.2±0.2,

[0071] The washing solution is 0.18mol / L sodium chloride, 0.015mol / L sodium citrate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com